EPS joogtada ah ee mashiinka maran

Gogoldhig

Qalabka EPS ee joogtada ah ee loo yaqaan 'preparance pre prephinc' ayaa loo shaqeeyaa si loo ballaariyo es eps-ka si loo isticmaalo cufnaanta, mashiinka si isdaba joog ah loogu sameeyo qaadashada ashyaa'da cayriinka ah iyo waxyaabaha la ballaariyey ee wax lagu ballaariyo oo la ballaariyo.

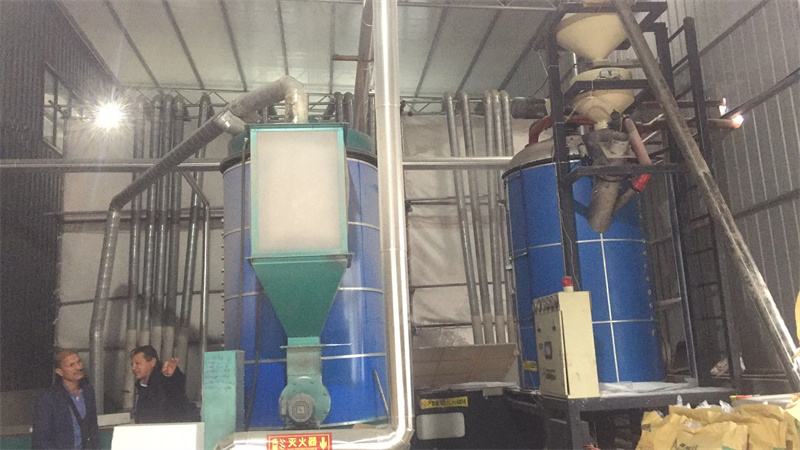

EPS Joogtada ah ee Mashiinka Pariamrance Preciarant oo leh conveyor daboolka, oo leh awood - aaladda ka baxsan aaladda ilaalinta. Xamuulka ballaarinta koowaad iyo kan labaad, qolka ballaarinta, gogosha jilicsan ee sariirta

Mashiinka joogtada ah ee loo yaqaan 'EPS joogtada ah ee mashiinka loo dulqaadanayo waa nooc ka mid ah mashiinka EPS ee la shaqeeya kontoroolka farsamada. EPS ceyriinka ayaa ugu horreysa waxaa laga buuxiyaa daboolka daboolka si loo ballaariyo xamuulka. Qeybta hoose ee xamuulka ayaa ah daboolka, si loogu dhaqaaqo sheyga xamuulka si loo ballaariyo qolka ballaarinta. Inta lagu gudajiro cagaar, caleenta cagaaran waxay si joogto ah ugu dhaqaaqdaa si ay u sameyso walxaha cufnaanta xitaa iyo labis. Qalabka ceyriinka ah u dhaqaaq qolka si joogto ah, ka dib markii uumiga, heerka shey si joogto ah u dhaqaaq, ilaa heerka maaddada ay ku timaaddo isku heer dekeda furitaanka ee dib-u-furista, ka dib waxbaa si otomaatig ah u qulqulaya. Furitaanka sii kordhashada dheecaanka ayaa ah, intaa sii dheeraadaan maaddada ay joogaan foosto, sidaa darteed hoose ee cufnaanta ayaa ah; Furitaanka dheecaanka dheecaanka ayaa ah, maaddada gaagaaban ee maaddada ku jirta foosto, sidaa darteed waxa kor u kaca cufnaanta ay tahay. Xakamaynta mashiinka sii socda ee sii wadida ah ee pre - mashiinka ballaarinta waa mid aad u fudud. Haddii cadaadiska uumiga uu deggan yahay ama uusan saameyn weyn ku yeelan cufnaanta ballaarinta. Sidaa darteed, mashiinkayaga sii socda ee sii socda ee ka hor - Si loo sameeyo cadaadiska uumi-baxa ee mashiinka xasilloon, waxaan u isticmaalnaa daboolka si aan ugu quudino sheyga xawaaraha yunifoonka, iyo cawska labiska iyo isku-darka labisku waa sida isku mid ah intii suurtogal ah.

EPS Styrofoam Mashiinka

| Wax | 10 | 1020 | |

| Qeybta ballaarinta | Dhexroor | Φ900mm | Φ1200mm |

| Mug | 1.2m³ | 2.2m³ | |

| Mugga la isticmaali karo | 0.8M³ | 1.5m³ | |

| Uumi | Gelitaan | DN25 | Dn40 |

| Isticmaal | 100 - 150kg / saac | 150 - 200KG / H | |

| Cadaadis | 0.6 - 0.8mpa | 0.6 - 0.8mpa | |

| Hawo isku buuqsan | Gelitaan | DN20 | DN20 |

| Cadaadis | 0.6 - 0.8mpa | 0.6 - 0.8mpa | |

| Biyo tuurid | Gelitaan | DN20 | DN20 |

| Wax dheeraadsin | 15G / 1 | 250kg / saacad | 250kg / saacad |

| 20G / 1 | 300kg / saacad | 300kg / saacad | |

| 25G / 1 | 350KG / H | 410kg / saacad | |

| 30g / 1 | 400kg / saacad | 500KG / H | |

| Khadka Gudbinta Qalabka | Dn100 | Φ150mm | |

| Awood | 10kw | 14.83kw | |

| Cucid | Ballaarinta koowaad | 12 - 30G / L | 14 - 30g / l |

| Ballaarinta labaad | 7 - 12G / L | 8 - 13G / L | |

| Guud ahaan cabirka | L * w * h | 4700 * 2900 * 3200 (mm) | 4905 * 4655 * 3250 (mm) |

| Culeys | 1600kg | 1800kg | |

| Dhererka Qolka ayaa loo baahan yahay | 3000mm | 3000mm | |

arrin