2020 Good Quality Eps Beads Reactor - EPS Raw Material Project – DONGSHEN

2020 Good Quality Eps Beads Reactor - EPS Raw Material Project – DONGSHENDetail:

Summary of EPS(Expandable PolyStyrene) raw material production

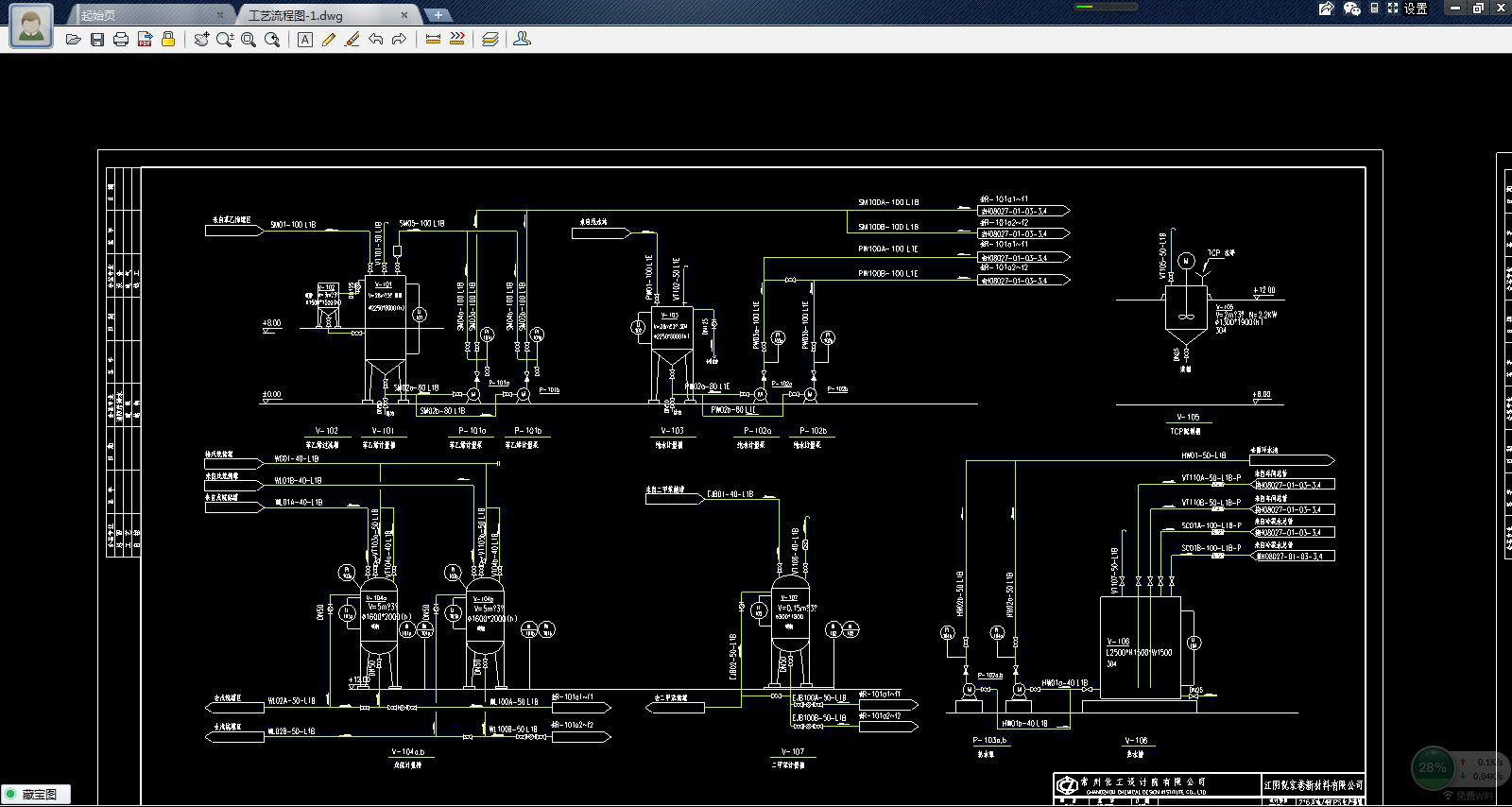

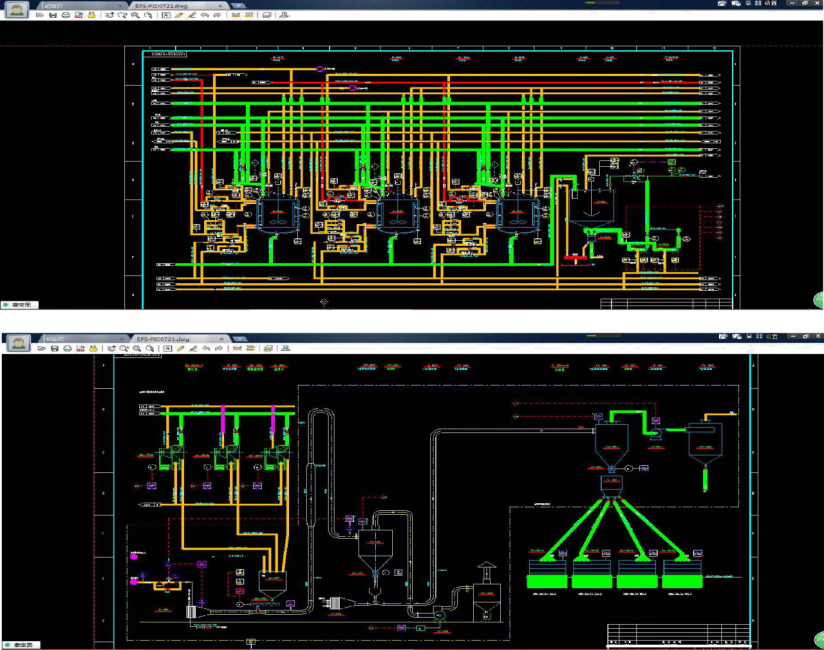

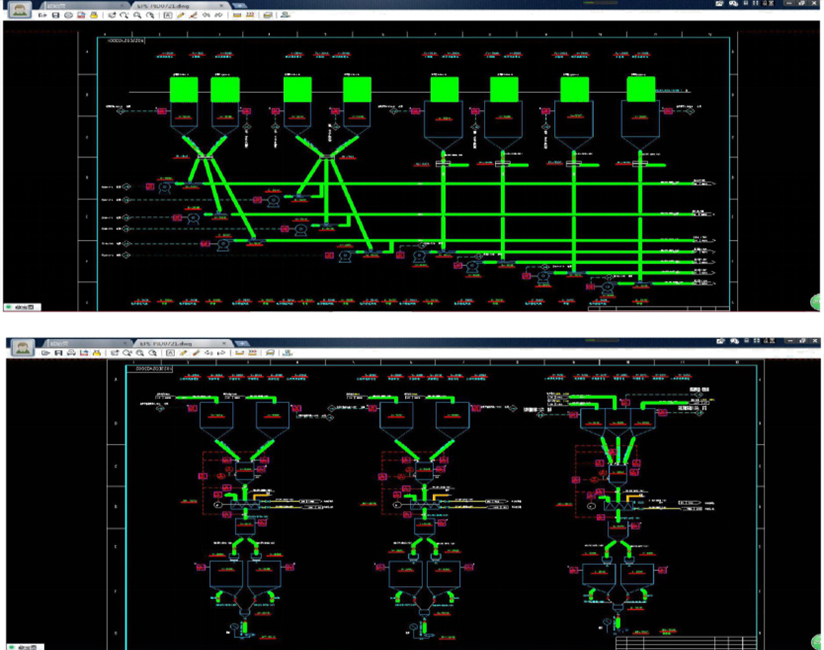

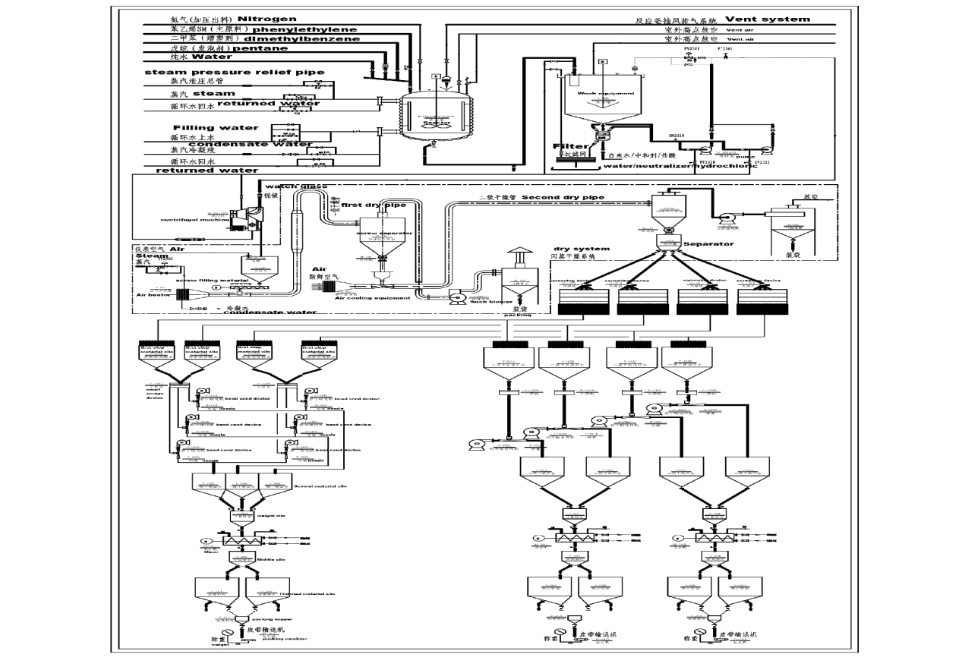

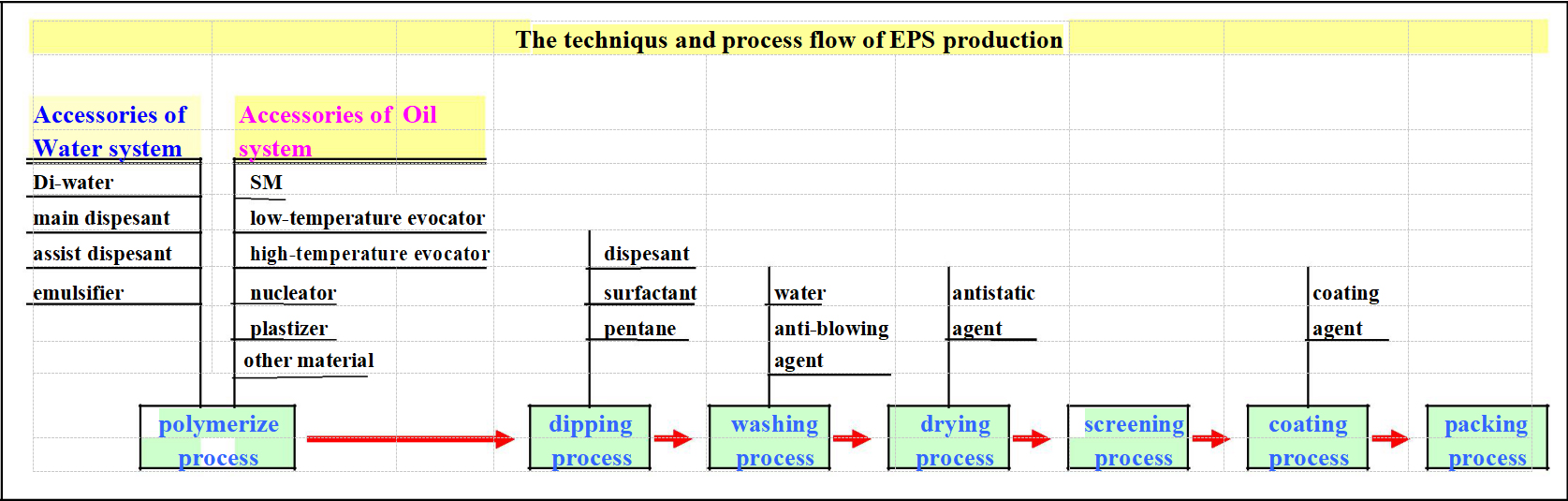

Process Flow introduction

Geedi socodka hal - Qaabka Tallaabada oo ay kujirto Pumomerization, Feejignaan, Qaling, Dhaqista, Dhaqida, Qalajinta, Kala-goynta, Imtixaanka Dareemiska, xirxiran. Celceliska wareegga wax soo saarka ee waqtiga soosaarka EPS waa 16 ~ 17 saacadood.

(1) Polymerization and Impregnation

POLMERMEMEMENTION IYO TILMAAMAHA LAGU SAMEEYAA FARSAMADA GUUD. Ugaarsi yar, SM ayaa polympirizize sm. Dhacdooyinka murugada leh, SM waa la kordhin doonaa oo la jajabinayaa, ka dib marka la soo koobo saliida SM-ka ee SM-ka laga joojiyo biyaha dartiis dartiis. Waxaa jira kala firdnaan oo ka joojinta biyaha si looga fogaado in loo yaqaan 'guntin' oo ay isku xiraan. Nidaamkan oo ah awoodda cidhifka waa iney ka weynaataa awoodda isku xirka si loo hubiyo in la yareeyo

Falcelinta Polymerization-ka ayaa ku shaqeeya dhibicda saliida ee saliida ee SM, kuleylka lagu sii daayo falcelinta waxaa laga qaadi doonaa biyaha qaboojinta. Si aad uguleyshato kuleylka waqtiga, waa inaan hubinaa sida caadiga ah shaqada dib-u-warshadaynta nidaamka biyaha dib-u-warshadaynta inta lagu gudajiro nidaamka falcelinta. Haddii kale, heerkulka ku dhex jira jawaabta ayaa aad u sarreysa, kaas oo horseedda falcelin deg deg ah iyo viscosity sare.

Nidaamka wax soo saarka ee Beedka ayaa gacanta lagu hayaa, inta lagu gudajiro hawsha, heerkulka waa in lagu xakameeyaa si looga fogaado isbeddelada weyn, haddii kale, tirada cabirku waa la ballaarin doonaa. Waqtigan xaadirka ah, inta badan indha-indheynta muunadaha ayaa muhiim u ah xakameynta cabirka guluubka.

By the adjust of light weight CaCO3 and TCP, the size of beads can be controlled.

Nidaamka DCS waxaa loo isticmaalaa xakameynta heerkulka inta lagu gudajiro hanaanka kuleylka, polympremization, wax lagu dhejiyo, sare, falcelin heerkulka, iyo qaboojinta. Si loo hubiyo in wax soo saarka badbaadada, nidaamka DCS uu xakameynayo falcelinta tilmaanta iyo waqtiga, iyo alaarmiga in ka badan - Heerkul ama kiiska Exprure.

Marka sicirka is-beddelashada ee 'SM-ka' ku dhawaad 75% (qiyaastii 4 illaa 5 saacadood heerkul joogto ah), tiro cayiman oo wakiil ah oo afuufa waa in lagu dari karaa. Ka dib markii la iibinayo iyo pomanmerization-ka waqtiga xaadirka ah iyo cadaadiska, waxaan heli karnaa guluusyada EPS.

Wakiilka afuufka ee loogu talagalay in lagu duro si loo cabbiro juttle bamka, oo si sax ah u miisaamay qalabka miisaanka. Ka dib sare - hanaanka kuyaala ee kuyaala, markii la qaboojinayo heerkulka cayiman, maaddada waxaa loo saari karaa haanta lagu dhaqo.

(2) Washing

Ciallinimada nimcada sida kala firidhsan iyo sclocullaes waa in laga saaraa dhaqitaanka. Nadiifinta ka dib, guluusyada EPS waxaa lagu qallajin doonaa fuuq-baxa Centrifugal si looga saaro inta badan biyaha dusha sare, oo ay diyaar u yihiin qalajinta.

We can also use de-foaming agent to remove impurities.

(3) Drying

Ka dib markii ay fuuq-baxa tillaabo ee korantada ka dib 3% hadhaaga biyaha dushiisa (maaddada biyaha ee aadka u sareysa ayaa loo baahan yahay, si hawshaan qalalan ee loo yaqaan 'EPS', inta lagu gudajiro hanaankan, guluusyada EPS waxaa ku qallajiya hawada kulul. Ku afuufaya dabayl kulul, biyaha dusha sare ee galka, ka dib gaaskan - Isku-darka adag ayaa ku soo dhacaya meel lagu shaandhadaa meela diiran oo ku yaal bartamaha buurta ee ku dhex socda bartamaha tuubbada. Sidan ayaa loo qalajinayaa guntin.

Shidaalka hawo kulul ka dib, ganaaxdu waxay u baahan tahay in lagu qaboojiyo dabayl qabow si loo sii yareeyo waxyaabaha biyaha ku jira, oo u diyaar garow baaritaanka. Si looga hortago uruurinta korantada, wakiilka ka hortaga tamarta ka hortaga waa in lagu daraa inta lagu gudajiro qalajinta.

The drying temperature is controlled by DCS system.

(4) Screening

The sizes of dried EPS beads are uneven, screening maching is needed to separate the beads by specification and transfer to different silos.

(5) Coating

Intii lagu gudajiray soo-saarka EPS, kaydinta, gaadiidka, gaadiidka iyo habka, baxsiga wakiilka afuufa waa lama huraan. Haddii wakiil aad u afuufaya, dhibaatooyin badan ayaa dhici doona, sida hoos udhaca heerka ballaarinta, oo ah cufnaanta, iwm.

(6) Package

Package the EPS beads according to different specification. The standard package weight is 25kg.

Purpose of packaging : conenience transportation, avoid the escape of blowing agent, and extend the guarantee period.

EPS Flow Chart

Case

Product detail pictures:

Related Product Guide:

Mashaariicda maaraynta ee hodanka ah ee Mashaariicda Maareynta iyo Hal U Adeegsiga Hal Moodeel Adeeg Samee Muhiimka Sare ee Isgaarsiinta Ganacsiga iyo Fahamkeenna fudud ee waxyaabaha aad ka fileyso2020 Mashruuca EPS ceyriinka - Dongshen, sheyga ayaa saadaalin doona adduunka oo dhan, sida: Awoodda wax soo saarka ee Angolo, oo ay ku taageerto soosaarka ashyaa'da, oo ay ka taliyaan isbedelka alaabada iyo sidoo kale Adeegyada iibka. Waxaan jeclaan lahayn inaan kula wadaagno fikradaheena oo aan soo dhaweyno faallooyinkaaga iyo su'aalahaaga.