Yakakwira - Kubata Electric Hot Wire Foam Cutter - Polystyrene block molding muchina

Zvigadzirwa zvechigadzirwa

Polystyrene Block Molding Malding Machine ine vacuum ndeyekunyorera EPS muchina kugadzira EPS block. EPS Mabhokisi anogona kutemwa kune mashiti emidziyo yeimba kana kurongedza. Zvigadzirwa zvakakosha zvakagadzirwa kubva EPS sandwich mapanera,

Polystyrene Block Molding Molding Muchina neVaCuum inogona kuburitsa yakakura EPS mabhuru emabhuruku, achishanda mukukurumidza kutenderera, uye zvidhinha zvese zvakatwasuka uye zvine simba mvura. Muchina unogona zvakare kuita kuti denderedzwa rakaderera rine hunhu hwakanaka. Inogona kuita yakanyanya density pa40g / l uye yakaderera density pa 4G / l.

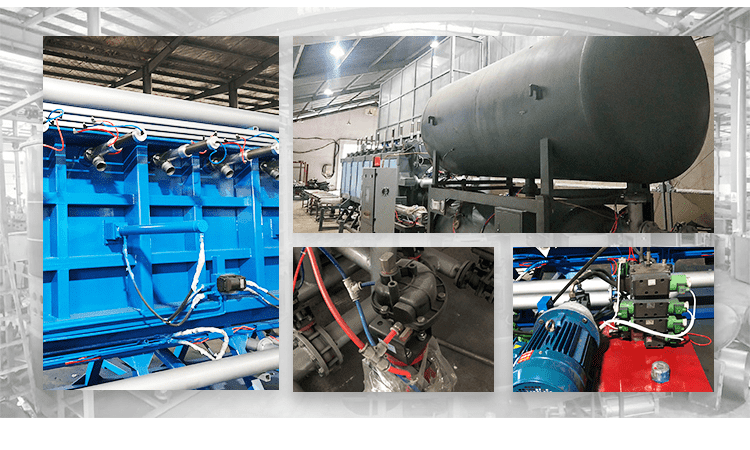

Polystyrene block Molding Molding Molding ine vacuum yakazara nemuchina wemuchina muviri, kudzora bhokisi, vacuum system, inorema system etc.

Polystyrene Block Molding Muchina ane vacuum zvakanakira:

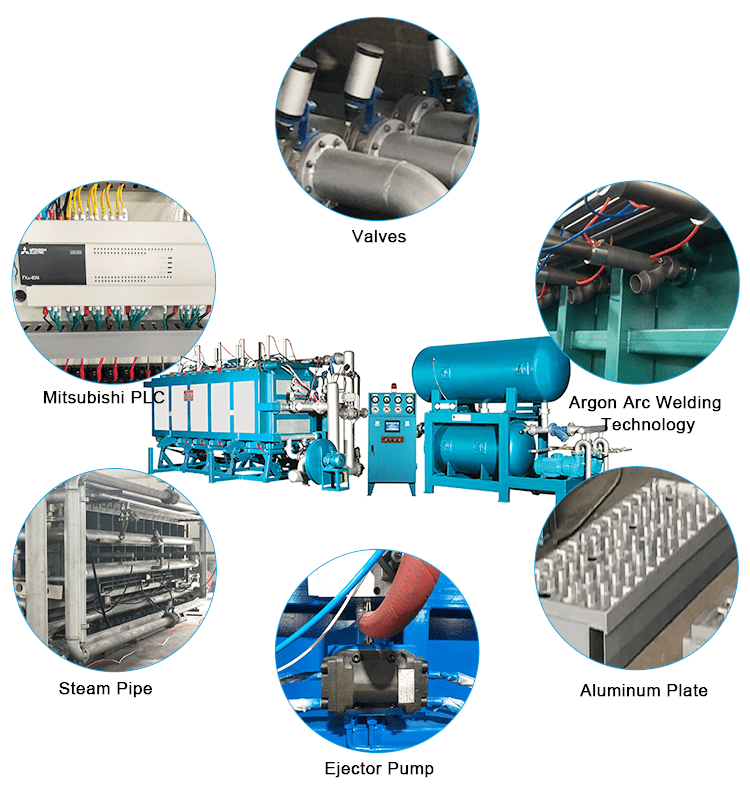

1.machine yakagadzirwa yakakwira - Simba Square Tubes uye Matangi Steel Mahwendefa;

2.machine inoshandisa 5mm gobvu aluminium steam mahwendefa ane teflon yekuvhara. Uye pasi peAluminium ndiro, hombe dzakatsigirwa dzakatsigirwa pane yakawanda huwandu dzinoiswa kuti dzidzivise aluminium plate fungidziro pasi pekumanikidzwa kwakanyanya. Aluminium plates haina't Chinja fomu mushure memakore gumi achishanda;

3.machine'S dzese mapanera matanhatu ari kuburikidza nekushatisa kurapwa kusunungura kushushikana kwekushushikana, saka kuti mapaneru haagoni kuremara pasi pekupisa kwakanyanya;

4.MACHAIN ine mimwe mitsetse yeSteam yekuve nechokwadi chekupfura kunyange mumabhawa, saka block fusion iri nani;

5.machine mahwendefa ane system yekudonha iri nani saka zvidhinha zvakaomeswa uye zvinogona kutemwa munguva pfupi;

6.Sezvamachina emuchina mahwendefa achibvisa, bhora kupfira, wozoita anti - ngura base pendi uye sosi yemuchina haisi nyore kuti ibviswe;

7.mazine shandisa smart pombi yekuputika uye yekupfura maitiro, inoona yakanaka yekufungidzira yemavhara ese ekuremekedza kwakanyanya uye yakaderera gersity;

8.Fastast kuzadza system uye inoshanda vacuum system inovimbisa muchina wekushanda, imwe neimwe block 4 ~ 8 maminitsi;

9.EJECHEMA ZVINOGONESWA neHydraulic Pump, saka ese ejectors anosundira uye adzokere nekukurumidza;

Zvigadzirwa zvinotsanangurwa zvinoshandiswa mumuchina zvakatengwa kunze kwenyika kana zvakakurumbira zvigadzirwa zvezvivakwa.

Main technical parameter

Chinhu | Unit | PB2000V | PB3000V | PB4000V | PB6000V | |

Kukura Kwemold Cavity | mm | 2040 * 1240 * 1030 | 3060 * 1240 * 1030 | 4080 * 1240 * 1030 | 6100 * 1240 * 1030 | |

Block size | mm | 2000 * 1200 * 1000 | 3000 * 1200 * 1000 | 4000 * 1200 * 1000 | 6000 * 1200 * 1000 | |

Steam | Kupinda | Inch | 2 '' (DN50) | 2 '' (DN50) | 6 '' (DN150) | 6 '' (DN150) |

Kushandiswa | Kg / kutenderera | 25 ~ 45 | 45 ~ 65 | 60 ~ 85 | 95 ~ 120 | |

Kumanikidzwa | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Akamanikidzwa Mhepo | Kupinda | Inch | 1.5 '' (DN40) | 1.5 '' (DN40) | 2 '' (DN50) | 2 '' (DN50) |

Kushandiswa | m³ / kutenderera | 1.5 ~ 2 | 1.5 ~ 2,5 | 1.8 ~ 2,5 | 2 ~ 3 | |

Kumanikidzwa | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Vacuum inotonhorera mvura | Kupinda | Inch | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) |

Kushandiswa | m³ / kutenderera | 0.4 | 0.6 | 0.8 | 1 | |

Kumanikidzwa | MPA | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | |

Kudhonza | Vacuum drain | Inch | 4 '' (DN100) | 5 '' (dn125) | 5 '' (dn125) | 6 '' (DN150) |

Pasi pejasi vent | Inch | 4 '' (DN100) | 5 '' (dn125) | 6 '' (DN150) | 6 '' (DN150) | |

Mhepo inotonhorera vent | Inch | 4 '' (DN100) | 4 '' (DN100) | 6 '' (DN150) | 6 '' (DN150) | |

Kugona kwe5kg / m³ | Min / kutenderera | 4 | 5 | 7 | 8 | |

Batanidza mutoro / simba | Kw | 19.75 | 23.75 | 24.5 | 32.25 | |

Yese Dimension (L * h * w) | mm | 5700 * 4000 * 2800 | 7200 * 4500 * 3000 | 11000 * 4500 * 3000 | 12600 * 4300 * 3100 | |

Uremu | Kg | 5000 | 6500 | 10000 | 14000 | |

Mhosva

Vhidhiyo Yakanangana

Our technical team is committed to supporting you in mastering the functionality of the Electric Hot Wire Foam Cutter. We provide comprehensive training and post-purchase support to assist you in harnessing the full potential of this versatile machine. Invest in the future of EPS block moulding with the Electric Hot Wire Foam Cutter from Dongshen, a machine that embodies innovation, efficiency, and performance like none other in the market. Revolutionize your EPS manufacturing process with the advanced technology of our Polystyrene Block Moulding Machine. Experience the Dongshen difference today.