Fekitori yakananga ice bhokisi kuumbwa kwePremium Bewering mharidzo

Chigadzirwa chikuru paramita

| Paramende | Kukosha |

|---|---|

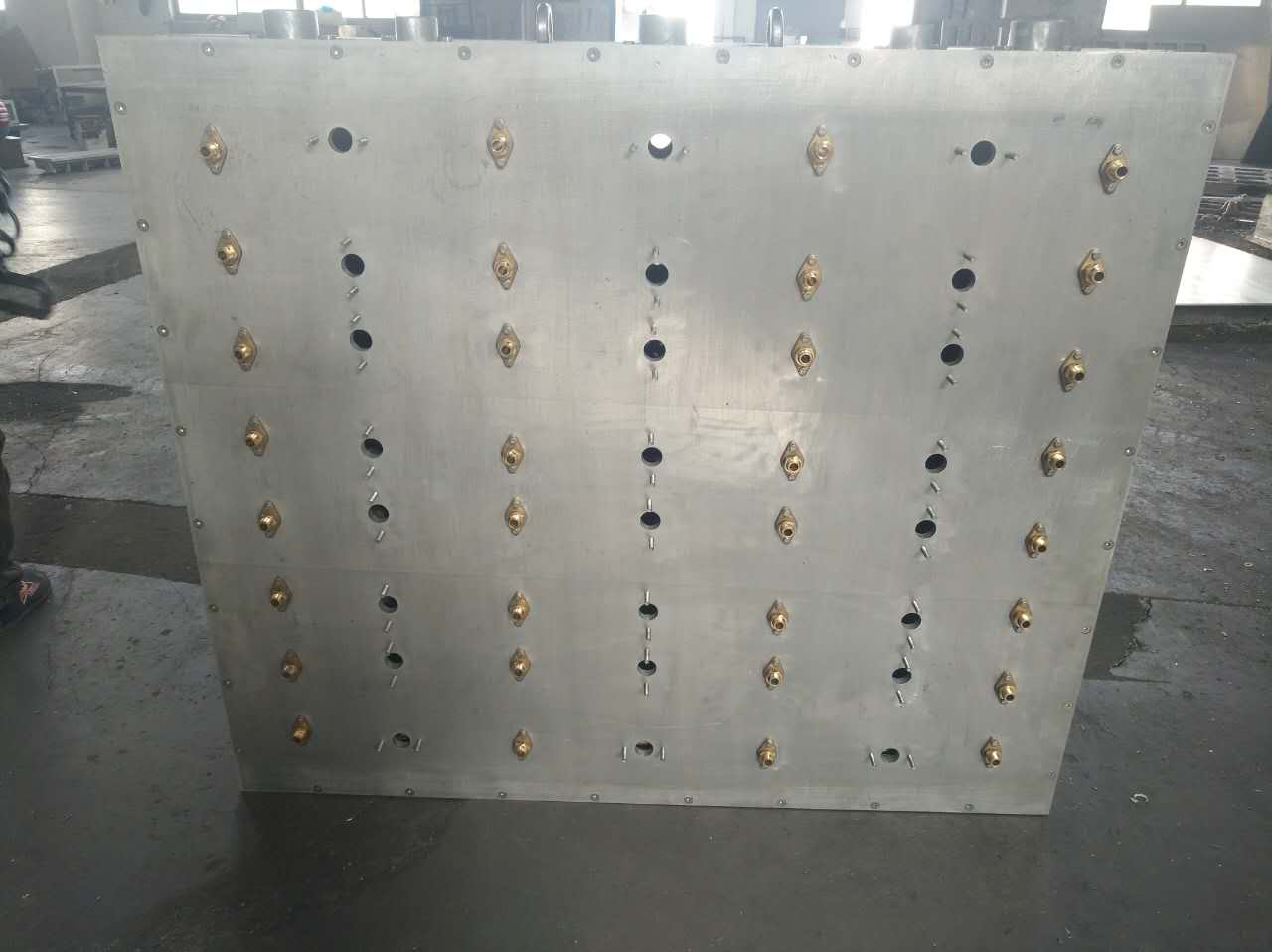

| MOLD zvinhu | Yakakwira - Emhando Aluminium |

| Plate Bightess | 15mm - 20mm |

| Steam Chamber | 1200 * 1000mm, 1400 * 1200mm, 1600 * 1350mm, 1750 * 1450 * 1450Mm |

| Mold size | 1120 * 920mm, 1320 * 1120mm, 1520 * 1270mm, 1670 * 1370mm |

| Machining | Zvizere cnc |

| Kurongedza | Plywood bhokisi |

| Nguva yekutumira | 25 ~ 40 mazuva |

Zvakajairika Zvigadzirwa Zvinyorwa

| Kutaurwa | Ruzivo |

|---|---|

| Zvinhu | Silicone, epurasitiki, simbi isina tsvina |

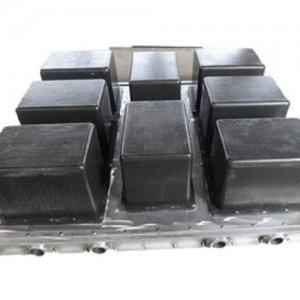

| Zvimiro zvinowanikwa | Standard cube, spherical, inlty, yakajeka ice, yakakura block |

| Shandisa kesi | Chinwiwa mharidzo, inoshandisa mashandisirwo, zvekurapa uye zvekushandisa uye zvesayenzi |

Chigadzirwa Chigadzirwa Kugadzirisa

Sekureva kwezviratidzo zvezviratidziro, maitiro ekugadzira ece bhokisi bhokisi maMold anosanganisira matanho mazhinji ekuti ave nechokwadi chekuratidzira mhando uye chaiyo. Pakutanga, yakakwira - mhando aluminium ingots inosarudzwa uye inokandwa mumhando yakaoma. Aya castings anobva aiswa pasi peCnc machining kuti uwane zviyero chaizvo uye zvigadziriso zvakatsiga. Teflon yekuvhara inoshandiswa kuti ive nechokwadi nyore nyore kutaura. Mhando dzekutonga dzinoongororwa dzinoitwa pamatanho akasiyana siyana kuti uve nechokwadi chekuti chigadzirwa chekupedzisira chinosangana nematanho ekupedzisira. Ichi chiitiko cheshokoio chinoguma ne ice bhokisi muumbi inogara uye inoshanda, yakakodzera kune mashandisirwo ekutengeserana uye epamba.

Chigadzirwa Chigadzirwa Chiitiko

Semupapeti ane masimba, ice bhokisi molds anoshandiswa mune dzakasiyana siyana zviitiko. Muindasitiri anomhanya, ivo vanoshandiswa kugadzira zvinoratidzika kuti inonaya echando chejasi uye zvimwe zvinwiwa, zvichisimudzira ruzivo rwevatengi. Vafambi vepamoyo vanoshandisa izvi zviumbwa kuti vagadzire maumbirwo eaya eaya emapuranga emapuranga, akafamba-famba, uye zvimwe. Mune minda yezvekurapa uye yesainzi, yunifomu chando chichangofanana mitezo yakakosha yekuedza uye maitiro ekuedza uye maitiro anodikanwa nekudzora kwakazara. Iyo inopesana neiyo ice bhokisi molds inoita kuti ive yakakosha pane akawanda maindasitiri.

Chigadzirwa mushure - Kutengesa Service

Isu tinopa takazara mushure - Kutengesa basa, kusanganisira technical tsigiro uye kugadzirisa dambudziko. Vatengi vanogona kubata nesu kuburikidza neemail kana foni yekukurumidza rubatsiro. Isu tinopa zvakare waranti yezvinhu uye nekushandira hurema.

Chigadzirwa chechigadzirwa

Yedu yeCox Bhokisi Mold dzakarongedzwa zvakachengeteka muPlywood mabhokisi kudzivirira kukuvara panguva yekufambisa. Isu tinopa sarudzo dzakasiyana dzekutumira dzinoenderana nezvinodiwa nemutengi uye nzvimbo yekuve nechokwadi chekutumira nguva uye zvakachengeteka.

Zvigadzirwa zvechigadzirwa

- Yakakwira - Yemhando yepamusoro Aluminium zvinhu zvinosimbisa kusimba uye hurefu.

- Zvizere cnc inokonzereswa kune chaiyo zviyero uye zvakatsiga nzvimbo.

- Teflon inovimbisa inovimbisa nyore nyore kutaura.

- Vane ruzivo engineering timu inokwanisa zvigadzirwa zvetsika.

- Kurumidza kuburitsa uye kunyatsoedza kutumirwa kusati kwatumirwa.

Chigadzirwa FAQ

1. Ndezvipi zvinhu zvinoshandiswa mukugadzira aya mold?

Iyo ice bhokisi kuumbwa inogadzirwa kubva kumusoro - kunaka aluminium, silicone, simbi, uye simbi isina simba, ichisimbisa kushanda uye kushanda zvakanaka.

2. Ndingakumbirisa tsika uye saizi?

Ehe, fekitari yedu inopa sarudzo dzesarudzo dzinoenderana nezvinodiwa zvako zvemagariro uye saizi.

3. Zvinotora nguva yakareba sei kuti utore?

Nguva yakajairika yekuzvitakura kubva pamazuva makumi maviri nemashanu kusvika makumi mana, zvichienderana nekuoma uye kugadziriswa kwebhokisi re ice rodu.

4. Chii chinonzi gobvu yeiyo aluminium plates inoshandiswa?

Mahwendefa ealuminium ane ukobvu kubva pa15mm kusvika ku20mm, kupa simba uye hupenyu hurefu.

5. Pane waranti yakapihwa here?

Ehe, isu tinopa waranti yekuremara mune zvekushandisa uye kushanda sechikamu chedu mushure me - Service Service.

6. Ini ndinochenesa sei molds?

Mamwe mamodeli, kunyanya silicone, arikunyepedzera - akachengeteka. Kune vamwe, kushambidza maoko pamwe nekushambadzira zvakapfava kunokurudzirwa kuchengetedza hunhu hwavo.

7. Ndezvipi zvinonyanya kuitika zvezviumbwa izvi?

Bhokisi redu remubhokisi kuumbwa rinoshandiswa zvakanyanya mukuratidzira mharidzo, zvisikwa zvinopesana, uye kunyange mune zvekurapa uye zvesayenzi.

8. Izvi zvinoumbwa zvinogona kudedera nyore?

Ehe, nekuda kweiyo teflon yekuvhara, zviumbwa zvedu zvinopa nyore nyore kutaura pasina kunamatira kana kutyora.

9. Zvakakodzera sei zviyero zvekuumbwa?

Zvitunha zvedu zvizere cnc michina, ichisimbisa kushivirira mukati me1mm yekunyatsojeka uye kunaka.

10. Iwe unopa rutsigiro rwekuisa fekitori itsva?

Ehe, isu tinopa kutsigirwa kwakazara kwekumisikidza mafekitori matsva ePs, kusanganisira dhizaini, nemachina uye technical rubatsiro.

Zvigadzirwa zvinopisa misoro

1. Iyo fekitori inove nechokwadi chekuti mhando ye ice bhokisi mold?

KuFekitori yedu, mhando yeiyo ice bhokisi mold inovimbiswa kuburikidza nemhando yepamusoro yekudzora matanho pane imwe neimwe nhanho yekugadzira. Isu tinosarudza yakakwira - mhando yemhando, shandisa cnc machining yekunyora, uye shandisa teflon kuunganidza nyore nyore kutaura. Kuongororwa kwakawandisa uye cheki kunoitwa pamberi pekutakura kuti uve nechokwadi chega chega chega chinosangana neyekutanga zviyero.

2. Chii chinoita kuti bhokisi re ice iite kubva mufekitori iyi yakasarudzika?

Bhokisi redu remubhokisi rinoumbwa dzakasarudzika nekuda kwekukwirira kwavo kusvika pakukwirira kwavo Pamusoro pezvo, timu yedu ine ruzivo rwekugadzira inogona kugadzira tsika molds zvichibva pane chaiwo zvinodiwa mutengi, zvichiita kuti vauye zvakanyanya uye kuvimbika kune dzakasiyana siyana application.

3. Inogona here fekitori inogadzirisa ice bhokisi muumbi maindasitiri akasiyana?

Ehe, mafekitori edu anoenderana nekugadzirisa bhokisi re ice mold kusangana nezvinodiwa zvevakasiyana-siyana. Kunyangwe yakakwira - Kupera Kwekumira mharidzo, kana mashandisiro anoita, kana kuti zvikumbiro zvesainzi, isu tinogona kugadzira uye kugadzira zviumbwa zvinokonzeresa zvinodikanwa zvegirazi rimwe nerimwe.

4. Mafekitori anotsigira vatengi mukugadzira mafekitori matsva ePS?

Isu tinopa kutsigirwa kwakazara kune vatengi kumisikidza mafekitori matsva ePS. Masevhisi edu anosanganisira kugadzira iyo fekitori chimiro, ichipa michina, uye kupa rubatsiro rwehunyanzvi. Chinangwa chedu ndechekubatsira vatengi vanogadzirisa maitiro avo ekugadzira, kuderedza kushandiswa kwesimba, uye kuwedzera kugona kwakazara.

5. Ndeapi maumbirwo akajairika akagadzirwa neiyo yefekitori yefekitori bhokisi mold?

Iyo fekitori inopa mhando dzakasiyana siyana kusanganisira zvigunwe zvemabhiza, zvinoshatisa, zvigadzirwa zvemukati, zviga zvigunwe zviyero, uye zvidhinha hombe. Aya maumbirwo akagadzirirwa kusangana nezvinodiwa zvakasiyana kubva pakushandiswa kwezuva nezuva kune zvinodikanwa zvine hunyanzvi kumusoro - kupera kwekudya uye kutsvagurudza kwesainzi.

6. Mafekitori anobata sei mushure me - kutengesa sevhisi yeiyo ice bhokisi molds?

Fekitori yedu inopa yakazara mushure - yekutengesa basa, kusanganisira technical tsigiro uye kugadzirisa dambudziko. Vatengi vanogona nyore kusvika isu kuburikidza neemail kana foni yekukurumidza rubatsiro. Isu tinopawo waranti kune chero hurema mune zvekushandisa kana kushanda, kuona kugutsikana kwevatengi.

7. Ndezvipi zvinhu zvinoshandiswa nefekitori kuti ugadzire ice bhokisi reCols?

Isu tinoshandisa yakakwira - zvigadzirwa zvemhando dzakadai sealuminium, silicone, yepurasitiki, uye simbi isina tsvina. Zvese zvinhu zvinopa zvikomborero zvakasarudzika, kubva pakuchinjika uye kusununguka kwekushandiswa kuimba yekusagadzikana uye nekunyatsoziva, kuve nechokwadi cheMold yedu kusangana nezvinodiwa zvevatengi zvakasiyana.

8. Ndeipi nguva yakajairika yekutumira yeiyo ice bhokisi kuumbwa kubva mufekitori?

Nguva yakajairika yekutumira nguva yebhokisi redu reCoce Molds kubva pamazuva makumi maviri nemashanu kusvika makumi mana. Iyi nguvaFrame inotibvumira kuti tive nechokwadi chekuti imwe neimwe yemumhepo inogadziriswa kune yakakwirira zviyero uye zvakanyatsoongororwa isati yatumirwa.

9. Iyo fekitori inove nechokwadi sei nyore kutaura kwemhando yechando?

Zvirinyore demouline Uku kuunganidza kunodzivirira chando kubva pakunamatira kune iyo mold, kubvumira kutarisisa uye kusagadzikana kubvisa maumbirwo echando.

10. Dai mafekitori anogona kushandura masampula evatengi kuita cad kana 3d dhizaini?

Ehe, mainjiniya edu ane ruzivo anogona kushandura samples dzevatengi muzvikamu zvakaringana kana kuti 3D kudhirowa. Kugona uku kunotitendera kuti titore kuumba maumbwa akagadziriswa anosangana chaizvo nezvakananga zvinodiwa zvemutengi, achivimbisa kukwana kwakakwana uye kwakakwana kuita.

Tsananguro yemifananidzo

Iko hakuna rondedzero yemufananidzo yechigadzirwa ichi