Advanced Styrofoam Melting Machine Yekukwira - Kubudirira Bhokisi Kuumbwa

Zvigadzirwa zvechigadzirwa

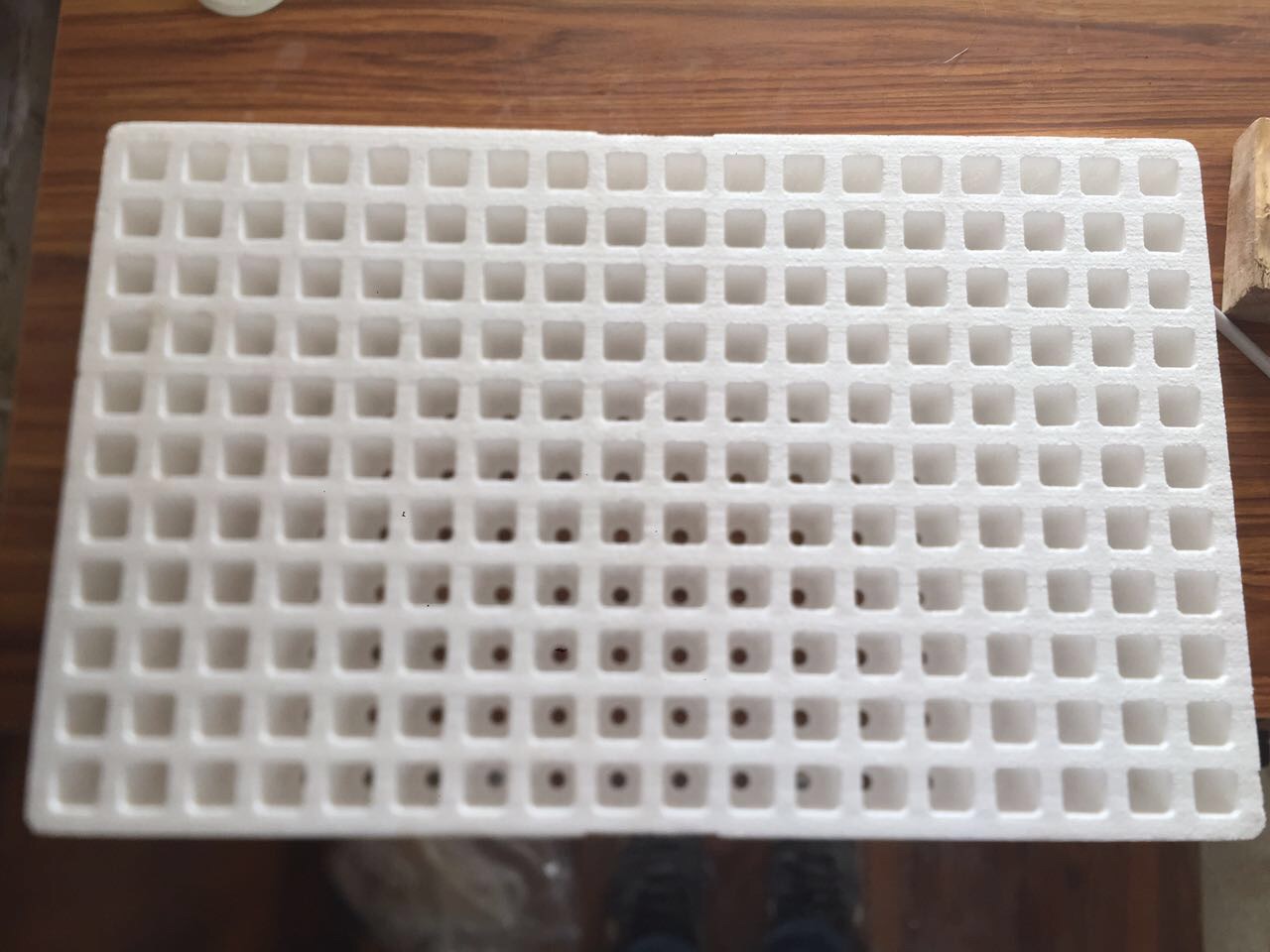

Styrofoam Shape Molding Muchina neKwakakwira Kubudirira kweBhokisi kune zvakanaka Vacuum System, Fast Hydraulic System, uye nekukurumidza Drainage system. Kune iyo yakafanana chigadzirwa, nguva yekutenderera muE Type Machine ndeye 25% ipfupi pane yakajairika muchina, uye kushandiswa kwesimba ndeye 25% shoma.

Styrofoam Shape Molding Muchina ane Bhokisi Rekupedza bhokisi rinopedzisa nePLC, kubata Screen, kuzadza system.

Zvikuru Zvekuita

Mahwendefa emuchina anogadzirwa nehombodo simbi simbi kuti igare refu;

Muchina une hunhu hwekuchinja-tsika, vacuum tank uye tangi yeCurnens yakapatsanurwa;

Machine Shandisa nekukurumidza hydraulic system, inochengetedza kuumbwa kuvhara uye yekuvhura nguva;

Nzira dzakasiyana dzinozadza dziripo kuti dzirege kuzadza dambudziko mune zvakakosha zvigadzirwa;

Muchina unoshandisa hombe pombi system, ichibvumira kuderera kudzvinyirira. 3 ~ 4bar Steam inogona kushanda muchina;

Machine Steam Kumanikidza uye Kupinda Kurovera kunodzorwa nekumanikidza kweGerman kumanikidza manometer uye kudzvinyirira varidzi vechirungu;

Zvikamu zvinoshandiswa mumushini zvinonyanya kuendesa kunze kwenyika uye zvakakurumbira zvigadzirwa, zvakaderera;

Muchina wacho nekusimudza makumbo, saka mutengi anongoda kuita chikuva chakareruka chekutanga kune vashandi.

Main technical parameter

| Chinhu | Unit | Fav1on 14: 12120000e | Favóans | Favana1700E | Favin77750e | |

| Mold Dimension | mm | 1200 * 1000 | 1400 * 1200 | 1600 * 1350 | 1750 * 1450 | |

| Max Chigadzirwa Chinyorwa | mm | 1000 * 800 * 400 | 1200 * 1000 * 400 | 1400 * 1150 * 400 | 1550 * 1250 * 400 | |

| Stroke | mm | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | |

| Steam | Kupinda | Inch | 3 '' (dn80) | 4 '' (DN100) | 4 '' (DN100) | 4 '' (DN100) |

| Kushandiswa | Kg / kutenderera | 4 ~ 7 | 5 ~ 9 | 6 ~ 10 | 6 ~ 11 | |

| Kumanikidza | MPA | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | |

| Kutonhora mvura | Kupinda | Inch | 2.5 '((dn65) | 3 '' (dn80) | 3 '' (dn80) | 3 '' (dn80) |

| Kushandiswa | Kg / kutenderera | 25 ~ 80 | 30 ~ 90 | 35 ~ 100 | 35 ~ 100 | |

| Kumanikidza | MPA | 0.3 ~ 0.5 | 0.3 ~ 0.5 | 0.3 ~ 0.5 | 0.3 ~ 0.5 | |

| Akamanikidzwa Mhepo | Kudzvinyirira kuderera kupinda | Inch | 2 '' (DN50) | 2.5 '((dn65) | 2.5 '((dn65) | 2.5 '((dn65) |

| Kudzvanywa kwakaderera | MPA | 0.4 | 0.4 | 0.4 | 0.4 | |

| Kukwirisa kwepamusoro kwekupinda | Inch | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | |

| Kumanikidza kwepamusoro | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

| Kushandiswa | m³ / kutenderera | 1.5 | 1.8 | 1.9 | 2 | |

| Kudhonza | Inch | 5 '' (dn125) | 6 '' (DN150) | 6 '' (DN150) | 6 '' (DN150) | |

| Capacity15kg / m³ | S | 60 ~ 110 | 60 ~ 120 | 60 ~ 120 | 60 ~ 120 | |

| Batanidza mutoro / simba | Kw | 9 | 12.5 | 14.5 | 16.5 | |

| Yese Dimension (L * W * H) | mm | 4700 * 206 * 4660 | 4700 * 2250 * 4660 | 4800 * 2530 * 4690 | 5080 * 2880 * 4790 | |

| Uremu | Kg | 5500 | 6000 | 6500 | 7000 | |

Mhosva

Vhidhiyo Yakanangana

The machine's fast hydraulic system enables seamless operation, reducing manual effort while augmenting productivity. Further, its quick drainage system ensures that the machine maintains its efficiency levels, ultimately improving the overall production rate. By integrating the Styrofoam Melting Machine into your manufacturing line, you can leverage the benefits of a high-performance, energy-efficient and cost-effective solution for your Styrofoam moulding needs. At Dongshen, we understand the importance of efficiency and reliability in manufacturing processes. Our Styrofoam Melting Machine offers you a solution that combines these essentials, empowering your business to deliver superior quality while enhancing production efficiency.