Maualuga EPS Block Wolding Fofoga Fofo mai le Taitai EPS esctor Gaosisi, Dongshen

Faamatalaga oloa

Polystyrene poloka masini o le masini ma le gaogao o se masini EPS e sili atu le lelei o le EPS poloka. E mafai ona tipi poloka EPS i pepa mo le faʻamaloloina o le fale poʻo le teuina. O oloa lauiloa na faia mai le EPS laupepa o le EPS sanuisi, 3D panels, totonu ma fafo atu o le puipui panels, meaafale afifiina, meaafale teuina ma isi

Polystyrene poloka masini e mafai ona maua ai le avanoa maualuga e mafai ona maua ai le maualuga o poloka eps, faigaluega i le vave taamilosaga, ma poloka uma o le susu. E mafai foi ona fai e le masini ni poloka pito i lalo ma lelei lelei. E mafai ona maua ai le maualuga maualuga i le 40g / l ma le maualalo maualalo i le 4G / l.

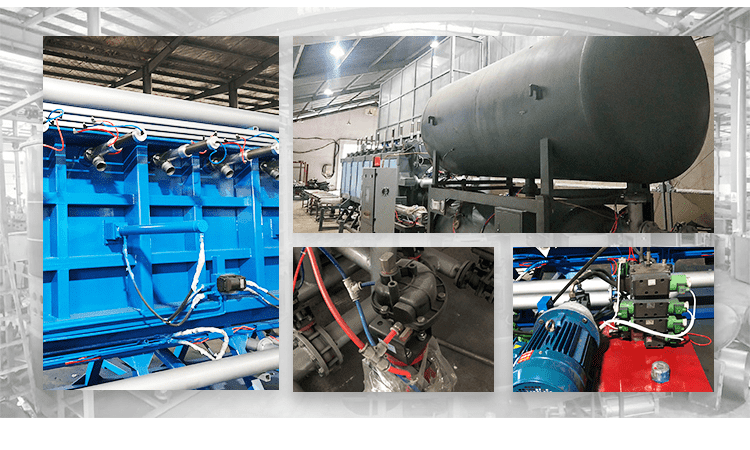

Polystyrene poloka masini o le tino ma le gaogao atoatoa ma le masini masini tino, pulea pusa, storum system, fuaina polokalama ma isi isi

Polystyrene poloka masini le lelei ma avanoa avanoa:

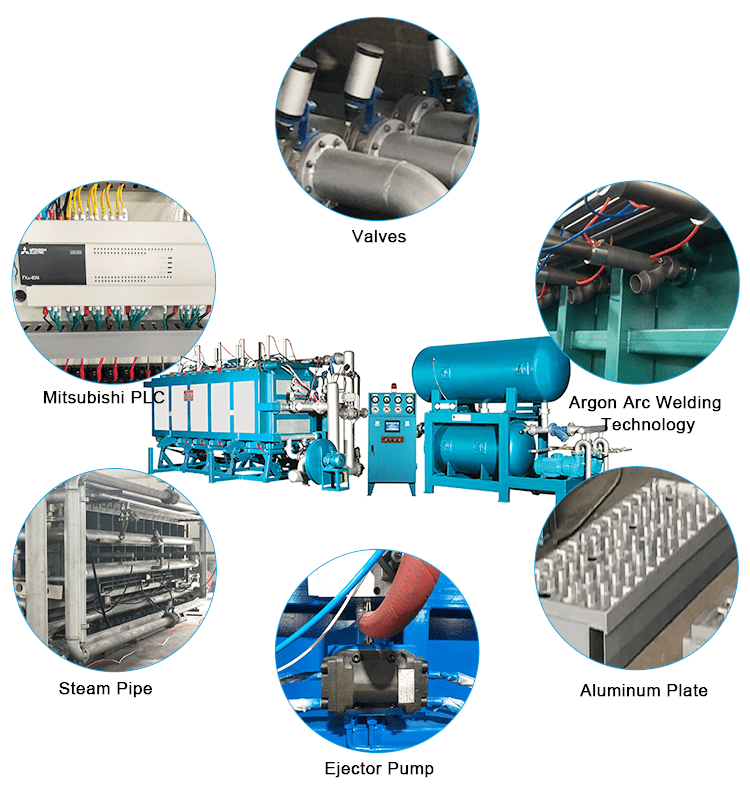

1. O le maualuga o le maualuga o le ata - malosi sikuea tubes ma mafiafia o papatusi uamea;

2.Machine faʻaaogaina 5mm mafiafia o le amonin steam faʻapipiʻi ma le tafilolapalapa. Ma i lalo o le alumini o le ipu, sili atu le lagolagoina lagolago i le tele o aofaiga ua tuu e aloese ai mai le alumini placle Alminim papatusi faia''T suia le ituaiga ina ua mavae le sefulu tausaga le faigaluega;

3.ma''s e ono laupapa e ono i le vevela togafitiga e faʻamatuʻu ai le mamafa o le popole, ina ia le mafai ona suia le maualuga o panels i lalo ole vevela maualuga;

4. Mo nisi laina steam e mautinoa ai le faʻapaʻu e tusa lava pe poloka, o le a le poloka paʻu e sili atu;

5.Machine papatusi o le sili atu alavai alavai i poloka e sili atu mamago ma mafai ona tipi i se taimi puupuu;

Po o masini paoteili e ala i le palapala e aveesea ai, polo felafolafoai, ona e le faigofie ai lea o le vali vali ma luga o le tino.

7.maʻea faʻaaoga le Smart Piping System System ma le faʻataʻitaʻiina o le faiga, mautinoa ai le inosia lelei le inosia o poloka poloka mo le maualuga maualuga;

8.E tatau ona faʻatumuina faiga ma lelei mo le lelei o le faiga e faʻatumu ai le masini vave galue, o poloka taʻitasi 4 ~ 8 minute;

9.Faʻavea e faʻatonutonuina e le pardialic pamu, o le a tuʻaʻi uma e tagata ma toe foi i le saoasaoa tutusa;

10. Ua faʻaaogaina e le pito i luga le masini i le masini e faʻaulufale mai oloa poʻo le taʻutaʻua o oloa.

Masani tomai faapitoa

Aitema | Iunite | Pb2000v | Pb3000v | PB4000V | PB6000V | |

Mold cavity tele | mm | 2040 * 1240 * 1030 | 3060 * 1240 * 1030 | 4080 * 1240 * 1030 | 6100 * 1240 * 1030 | |

Poloka lapoa | mm | 2000 * 1200 * 1000 | 3000 * 1200 * 1000 | 4000 * 1200 * 1000 | 6000 * 1200 * 1000 | |

Fulufulu | Ulufalega | Inisi | 2 '' (DN50) | 2 '' (DN50) | 6 '' (DN150) | 6 '' (DN150) |

Taumafaina | Kg / taamilosaga | 25 ~ 45 | 45 ~ 65 | 60 ~ 85 | 95 ~ 120 | |

Omiga | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Taofia Air | Ulufalega | Inisi | 1.5 '' (DN40) | 1.5 '' (DN40) | 2 '' (DN50) | 2 '' (DN50) |

Taumafaina | m³ / taamilosaga | 1.5 ~ 2 | 1.5 ~ 2.5 | 1.8 ~ 2.5 | 2 ~ 3 | |

Omiga | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Suavai gaogao vai | Ulufalega | Inisi | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) |

Taumafaina | m³ / taamilosaga | 0.4 | 0.6 | 0.8 | 1 | |

Omiga | Mpa | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | |

Fefaaaiina | Alavai alavai | Inisi | 4 '' (DN100) | 5 '' (DN125) | 5 '' (DN125) | 6 '' (DN150) |

Lalo steam vent | Inisi | 4 '' (DN100) | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | |

O le ea malulu o le ea | Inisi | 4 '' (DN100) | 4 '' (DN100) | 6 '' (DN150) | 6 '' (DN150) | |

Tulaga 15kg / m³ | Min / taamilosaga | 4 | 5 | 7 | 8 | |

Fesootai avega / mana | Kw | 19.75 | 23.75 | 24.5 | 32.25 | |

Aotelega lautele (L * h * w) | mm | 5700 * 4000 * 2800 | 7200 * 4500 * 3000 | 11000 * 4500 * 3000 | 12600 * 4500 * 3100 | |

Mamafa | Kg | 5000 | 6500 | 10000 | 14000 | |

Mataupu

Fesootai vitio

As an Eps Ejector Manufacturer, our machine's design incorporates a vacuum system, ensuring precise moulding of EPS blocks. This feature provides remarkable savings in terms of time and energy, contributing to an eco-friendly manufacturing process. Our product is not just about making EPS blocks; it's about delivering quality, efficiency, and sustainability in every block produced. At DongShen, we understand the needs of the industry. Our commitment as an Eps Ejector Manufacturer goes beyond just delivering machines; we provide full-fledged solutions to assist our clients in enhancing their manufacturing capabilities. By choosing our Polystyrene block moulding machine with vacuum, you choose superior performance, quality, and sustainability. Explore our innovative product range and make a smart choice for your business. Partner with DongShen, your trusted Eps Ejector Manufacturer, to leverage the power of advanced block moulding solutions.