Tulaga ese eps tipi: o lau sili styrofoam poloka poloka fua tali

Faamatalaga oloa

ETPS Styrofoam poloka masini o loʻo faʻaaogaina e faia ai poloka eps, ona tipi lea o pepa mo le faʻamaloloina o le fale pe faʻapipiʻi. O oloa lauiloa na faia mai le EPS laupepa o le EPS sanuisi, 3D panels, totonu ma fafo atu o le puipui panels, meaafale afifiina, meaafale teuina ma isi

E talafeagai le poloka o masini ePS e talafeagai mo le mafai ona faia mo le malosi o le faʻaaogaina mo le malosi o le talosaga. I le faʻapitoa tekonolosi, o le matou ES Styrofoam poloka masini e mafai ona faia ai le 4G / l degnmity poloka, poloka saʻo ma lelei lelei.

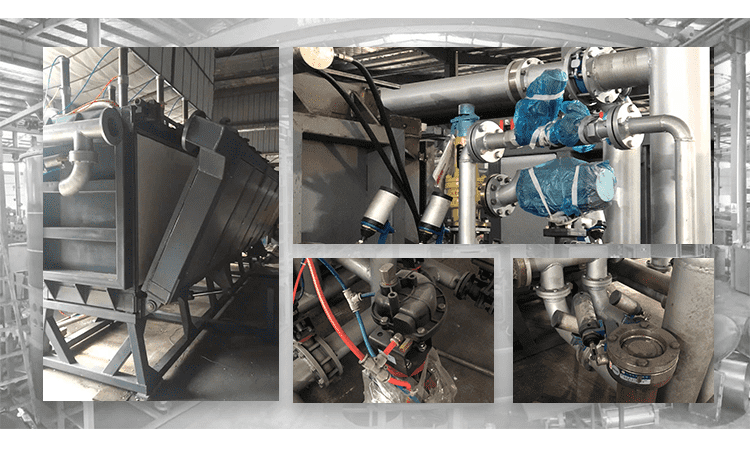

Masini faʻatumu ma le tino tele, faʻatonutonu pusa, alatoto, fuaina faiga ma isi ma isi

Faavae autu

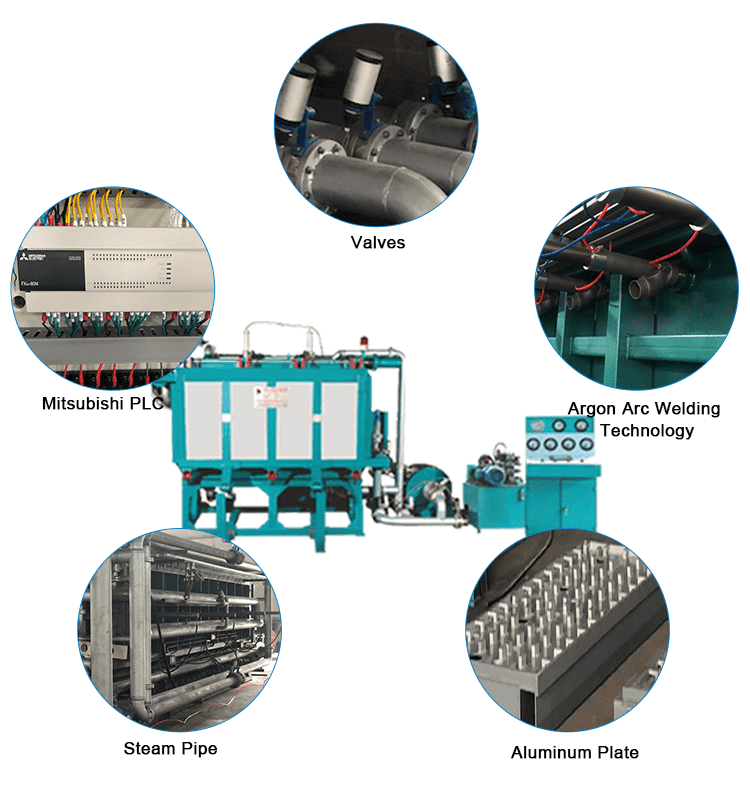

1. O le masini o loʻo faʻaaogaina Mtinosbishi Pluc ma Wortephing Stond Scrends mo otometi tatalaina le tatalaina o le Veld Replows, o loʻo tumu, vevela, o le vevela o le vaʻalele, o le vevela, o le vevela, o le vevela, o le vevela, o le vevela, o le vevela, o le vevela, o le vevela vevela, ea.

2. O le masini uma e ono potu o loʻo i le vevela togafitiga e faʻamatuʻu ai le faʻamaloloina o le popole, ina ia le mafai ona suia ai le maualuga o panela i lalo o le vevela maualuga;

3. Mod cavity o loʻo faia i le faʻapitoa Alininim o le Platey Platey ma le maualuga - Lelei le vevela o le alavai, o le alumini o le mafiafia 5mm, ma tefelon cheat mo faigofie demoulding.

4. O le masini na tu i luga o le maualuga - boot blower mo le lafoina mea. O le malu o loʻo faia e ala i le faʻaaogaina o le ea.

5. O le masini laupapa e mai i le maualuga - lelei le faʻailoga uʻamea, e ala i le vevela togafitiga, malosi ma leai fua.

6. E le mafai ona pulea e le pardraulic pamu, o le a pei o tagata uma e tuleia ma toe foi ile saoasaoa tutusa;

Masani tomai faapitoa

Aitema | Iunite | PB2000A | Pb3000A | PB4000A | PB6000A | |

Mold cavity tele | mm | 2040 * 1240 * 630 | 3060 * 1240 * 630 | 4080 * 1240 * 630 | 6100 * 1240 * 630 | |

Poloka lapoa | mm | 2000 * 1200 * 600 | 3000 * 1200 * 600 | 4000 * 1200 * 600 | 6000 * 1200 * 600 | |

Fulufulu | Ulufalega | Inisi | Mai le DN80 | Mai le DN80 | DN100 | Dn150 |

Taumafaina | Kg / taamilosaga | 18 ~ 25 | 25 ~ 35 | 40 ~ 50 | 55 ~ 65 | |

Omiga | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Taofia Air | Ulufalega | Inisi | DN40 | DN40 | Mon50 | Mon50 |

Taumafaina | m³ / taamilosaga | 1 ~ 1.2 | 1.2 ~ 1.6 | 1.6 ~ 2 | 2 ~ 2.2 | |

Omiga | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Fefaaaiina | Steam vent | Inisi | DN100 | Dn150 | Dn150 | Dn150 |

Tulaga 15kg / m³ | Min / taamilosaga | 4 | 5 | 7 | 8 | |

Fesootai avega / mana | Kw | 6 | 8 | 9.5 | 9.5 | |

Aotelega lautele (L * h * w) | mm | 3800 * 2000 * 2100 | 5100 * 2300 * 2100 | 6100 * 2300 * 2200 | 8200 * 2500 * 3100 | |

Mamafa | Kg | 3500 | 5000 | 6500 | 9000 | |

Mataupu

Fesootai vitio

From the first use, the EPS Cutter demonstrates how effortlessly it takes an EPS block and transforms it into a molded masterpiece. The results are uniformly shaped styrofoam sheets that exceed expectations and truly sets it apart from the competition. Whatever your EPS block molding needs are, our EPS Cutter is here to deliver. It is not just a machine; it is your partner in ensuring that every EPS block is molded to perfection. Try our EPS Cutter today and experience a new standard in EPS block molding efficiency.