Leading Thermocol Molding Machine Supplier - Discover Dongshen's Excellence

Intangiriro

EPS block moulding machine supplier is one of the biggest EPS machine supplier in China. The EPS block moulding machine is used to make EPS blocks, then cut to sheets for house insulation or packing. Popular products made from EPS sheets are EPS sandwich panels, 3D panels, inner and outer wall insulation panels, glass packing, furniture packing etc.

EPS block moulding machine is suitable for small capacity request and low density blocks production, it’s economic EPS machine. With special technology, our EPS block moulding machine can make 4g/l density blocks, block is straight and of good quality.

Machine completes with main body, control box, blower, weighing system etc.

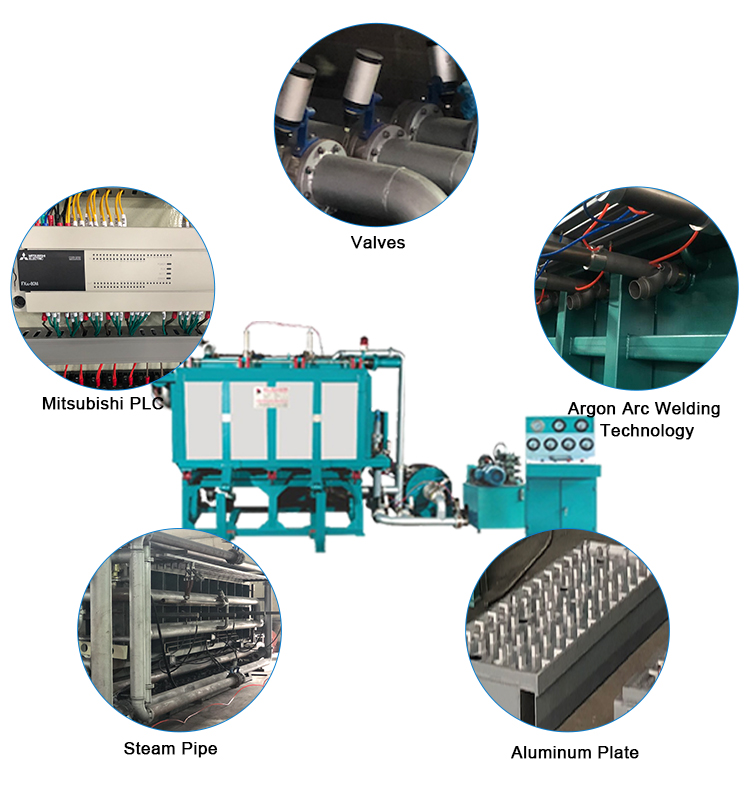

Ibiranga imashini

1. The machine adopts Mitsubishi PLC and Winview touch screen for automatic mould opening, mould closing, material filling, steaming, temperature keeping, air cooling, demoulding and ejecting.

2. Machine’s all six panels are through heat treatment to release welding stress, so that panels cannot deform under high temperature;

3. Mould cavity is made of special aluminum alloy plate with high-efficiency heat conduction, aluminum plate thickness 5mm, with Teflon coating for easy demoulding.

4. The machine set up high-pressure blower for suction material. Cooling is done by convection air by blower.

5. Machine plates are from high-quality steel profile, through heat treatment, strong and no deformation.

6. Ejection is controlled by hydraulic pump, so all ejectors push and return at same speed;

Ikintu | Igice | Pb2000A | Pb3000A | PB4000A | Pb6000A | |

Ingano ya COLD | mm | 2040 * 1240 * 630 | 3060 * 1240 * 630 | 4080 * 1240 * 630 | 6100 * 1240 * 630 | |

Ingano | mm | 2000 * 1200 * 600 | 3000 * 1200 * 600 | 4000 * 1200 * 600 | 6000 * 1200 * 600 | |

Icyuya | Kwinjira | Santimetero | Dn80 | Dn80 | Dn100 | Dn150 |

Gukoresha | Kg / cycle | 18 ~ 25 | 25 ~ 35 | 40 ~ 50 | 55 ~ 65 | |

Igitutu | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Umwuka ufunzwe | Kwinjira | Santimetero | Dn40 | Dn40 | DN50 | DN50 |

Gukoresha | m³ / cycle | 1 ~ 1.2 | 1.2 ~ 1.6 | 1.6 ~ 2 | 2 ~ 2.2 | |

Igitutu | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Imiyoboro | Vent | Santimetero | Dn100 | Dn150 | Dn150 | Dn150 |

Ubushobozi bwa 15kg / m³ | Min / ukwezi | 4 | 5 | 7 | 8 | |

Huza umutwaro / imbaraga | Kw | 6 | 8 | 9.5 | 9.5 | |

Rusange (L * h * w) | mm | 3800 * 2000 * 2100 | 5100 * 2300 * 2100 | 6100 * 2300 * 2200 | 8200 * 2500 * 3100 | |

Uburemere | Kg | 3500 | 5000 | 6500 | 9000 | |

urubanza

As we strive to uphold our place in the market, we place great emphasis on customer service. Our reputable status in the industry was built on trust and the provision of high-quality machines that cater to our customers' needs. Therefore, we commit ourselves to ensure our customers have access to the best Thermocol Molding Machines in the market, reflecting our vision for operational excellence. Our expansive portfolio entails a plethora of Thermocol Molding Machines that cater to a wide variety of needs. Whether it is for small-scale production or for massive industrial needs, Dongshen's machines stand the test of time and efficiency. Choose Dongshen, for a journey of growth and success with our exceptional Thermocol Molding Machine. Put your trust in us, the leading Thermocol Molding Machine supplier in China, and propel your business to new heights.