High-Quality EPS Block Moulding Machine from DongShen, the Trusted EPS Machine Manufacturer

Produktdetaljer

EPS expandable polystyrene machine manufacturer has efficient vacuum system, fast hydraulic system, and fast drainage system. For det samme produktet er syklustiden i E -type maskin 25% kortere enn i normal maskin, og energiforbruket er 25% mindre.

EPS expandable polystyrene machine manufacturer completes with PLC, touch screen, filling system, efficient vacuum system, hydraulic system, electric box

Hovedfunksjoner

Machine plates are made of thicker steel plates so it’s long lasting;

Machine has efficient vertical vacuum system, vacuum tank and condenser tank separate;

Machine use fast hydraulic system, saving mould closing and opening time, using high pressure oil cylinder, hydraulic pressure 140-145bar, hydraulic speed up to 250mm/s.

Different filling methods are available to avoid filling problem in special products, back pressure filling, normal pressure filling, pulse filling, pressurized filing etc choice.

Machine uses big pipe system, allowing low pressure steaming. 3 ~ 4bars damp kan fungere maskinen;

Machine heating system uses German pressure sensor to control steam pressure.

Components used in the machine are mostly imported and famous branded products, low malfunction;

Machine with lifting legs, so client only need to make a simple working platform for workers.

Maskindampforbruk mindre og arbeidseffektivitet høyere.

Hoved tekniske parametere

| Punkt | Enhet | FAV1200E | FAV1400E | FAV1600E | FAV1750E | |

| Mold dimensjon | mm | 1200*1000 | 1400*1200 | 1600*1350 | 1750*1450 | |

| Maks produktdimensjon | mm | 1000*800*400 | 1200*1000*400 | 1400*1150*400 | 1550*1250*400 | |

| Hjerneslag | mm | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | |

| Damp | Inngang | Tomme | 3 '' (DN80) | 4 '' (DN100) | 4 '' (DN100) | 4 '' (DN100) |

| Forbruk | Kg/syklus | 4 ~ 7 | 5 ~ 9 | 6 ~ 10 | 6 ~ 11 | |

| Trykk | MPA | 0,4 ~ 0,6 | 0,4 ~ 0,6 | 0,4 ~ 0,6 | 0,4 ~ 0,6 | |

| Kjølevann | Inngang | Tomme | 2.5 '' (DN65) | 3 '' (DN80) | 3 '' (DN80) | 3 '' (DN80) |

| Forbruk | Kg/syklus | 25 ~ 80 | 30 ~ 90 | 35 ~ 100 | 35 ~ 100 | |

| Trykk | MPA | 0,3 ~ 0,5 | 0,3 ~ 0,5 | 0,3 ~ 0,5 | 0,3 ~ 0,5 | |

| Trykkluft | Lavt trykkinngang | Tomme | 2 '' (DN50) | 2.5 '' (DN65) | 2.5 '' (DN65) | 2.5 '' (DN65) |

| Lavt trykk | MPA | 0.4 | 0.4 | 0.4 | 0.4 | |

| Høyt trykkinngang | Tomme | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | |

| Høyt trykk | MPA | 0,6 ~ 0,8 | 0,6 ~ 0,8 | 0,6 ~ 0,8 | 0,6 ~ 0,8 | |

| Forbruk | m³/syklus | 1.5 | 1.8 | 1.9 | 2 | |

| Drenering | Tomme | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | 6 '' (DN150) | |

| Kapasitet15kg/m³ | S | 60 ~ 110 | 60 ~ 120 | 60 ~ 120 | 60 ~ 120 | |

| Koble belastning/kraft | Kw | 9 | 12.5 | 14.5 | 16.5 | |

| Generell dimensjon (l*w*h) | mm | 4700*2000*4660 | 4700*2250*4660 | 4800*2530*4690 | 5080*2880*4790 | |

| Vekt | Kg | 5500 | 6000 | 6500 | 7000 | |

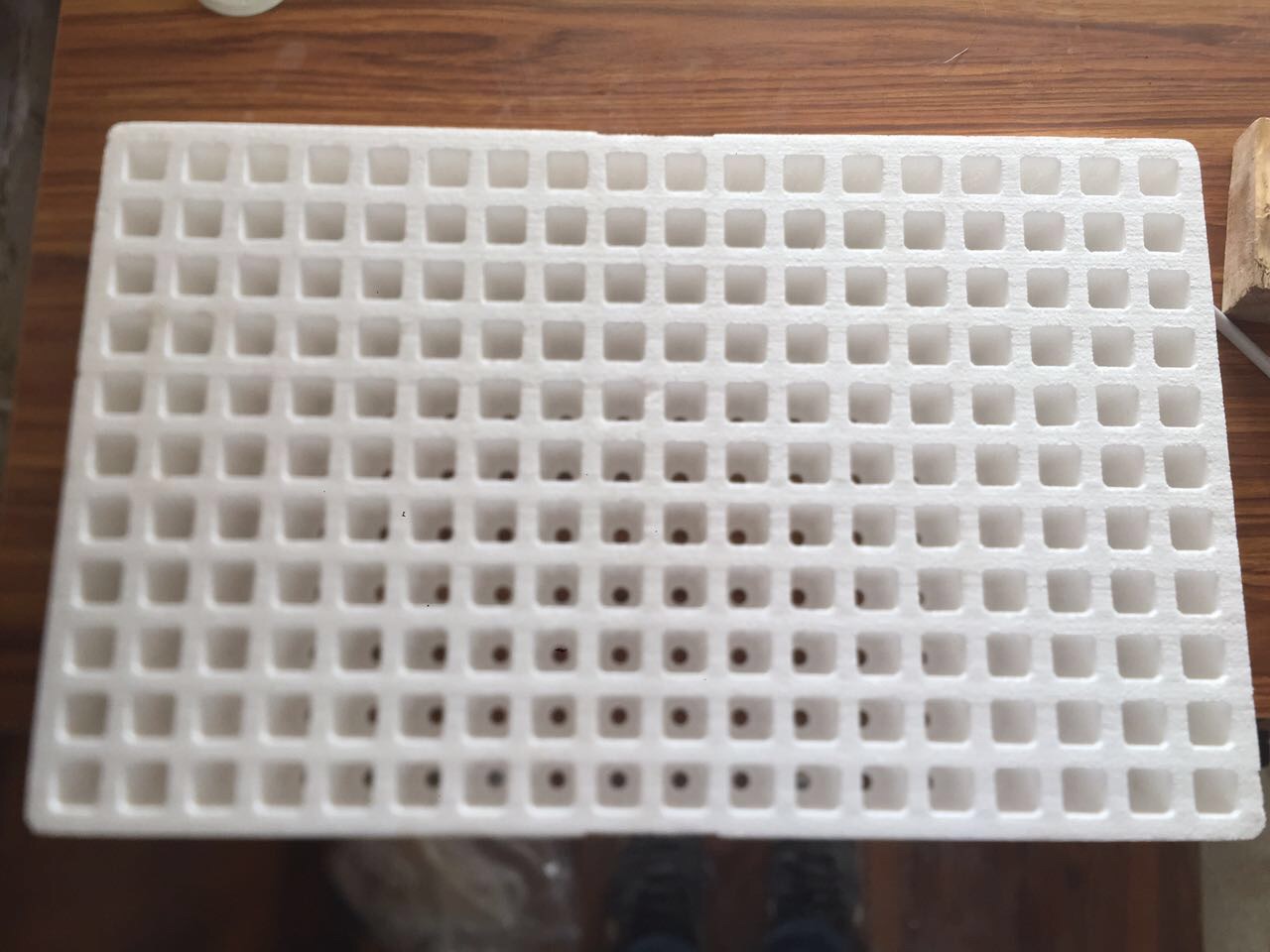

Sak

Relatert video

DongShen offers a wide range of machines to suit every EPS need. From EPS Injection Moulding Machine to EPS Sheet Making Machine, EPS Preforming Machine, EPS Panel Making Machine, EPS Block Cutting Machine, and more, we have you covered. Experience the power of efficient EPS production with DongShen, your reliable EPS Machine Manufacturer. Our commitment to quality and innovation is what keeps us at the top of the EPS machine manufacturing industry.