Poraka Poraka Poraka Poraka Aukati mai i te kaiarahi i te Kaihanga Kaihanga Kaihanga Kaihanga, Dongshen

Taipitopito Hua

Ko te miihini miihini a Polystyrene me te miihini he miihini e whai ana i te miihini EPS hei hanga EPS Poraka. Ka taea te tapahi i nga poraka EPS ki nga pepa mo te whakakii i te whare, ki te kohi ranei. Ko nga hua rongonui i hangaia mai i nga pepa EPS ko EPS Sandwich Panels, 3D nga paparanga 3 me te waho o te pakitara o te pakitara, te kapi karaihe, he aha nga taonga.

Ko te miihini miihini a Polystyrene me te valuuum ka taea te whakaputa i nga Poraka EPS nui, e mahi tika ana i te huringa tere, me te kaha o nga poraka me te makuku o te wai. Ka taea hoki e te miihini te hanga poraka iti me te kounga pai. Ka taea e ia te hanga i te kaha nui i te 40G / L me te iti o te kaha i te 4G / l.

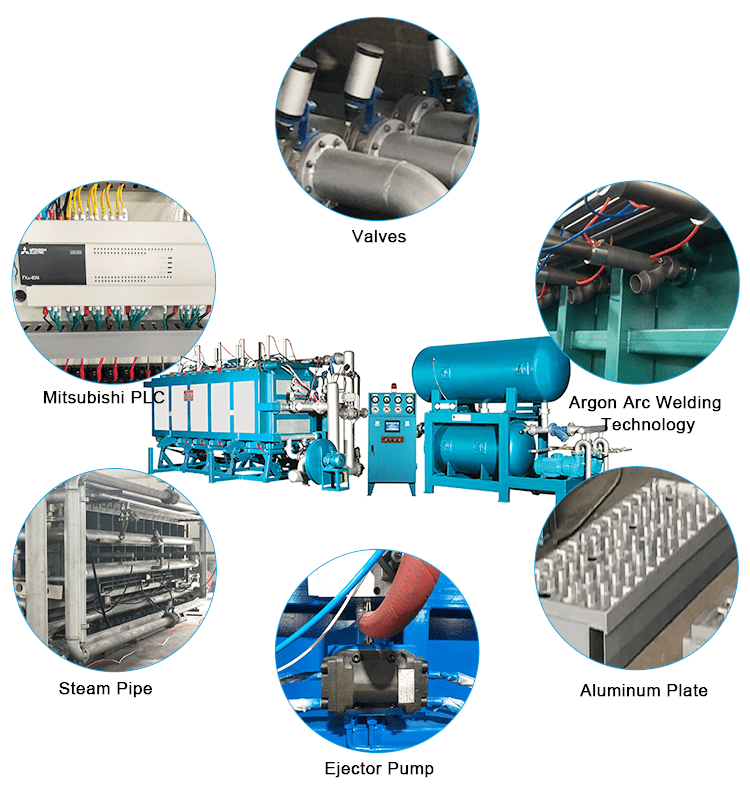

Polystyrene poraka miihini paninga me te waatea me te waatea me te miihini miihini matua, pouaka whakahaere, punaha valuuum, punaha taumaha me era atu.

Polystyrene poraka miihini paninga me nga painga mutunga:

1.Machine te mea tiketike - Te ngongo tapawha me nga papa kowiri tira;

2.Machine te whakamahi i nga pereti konumohe konumohe tino nui me te paninga a Teflon. A i raro i te pereti konumohe, ko nga tautoko rahi nui i te nui ka whakanohohia kia kore ai te konumohe konumohe i raro i te pehanga teitei. Ko nga papa konumohe kaore e'Huringa Huri i muri i nga tau kotahi tekau e mahi ana;

3.Machine'S E ono nga panui i roto i te maimoatanga wera hei tuku i te ahotea o te awangawanga, kia kore ai e taea e nga papa te whakapoke i te pāmahana tiketike;

4.Machine me etahi atu raina Steam hei whakarite i te haehae tae noa ki nga poraka, kia pai ake te whakakoretanga;

5.Ko te punaha 5.Machine te pai o te punaha wai kia maroke ake ai nga poraka ka taea te tapahi i te wa poto;

6.A nga pereti miihini ma te waikura, te rehu poro, ka mahi i te peita papaaho me te peita mata, na te miihini miihini kaore e tino tiakina;

7.Machine te whakamahi i te punaha pipi tohu atamai me te tukatuka, te whakarite i te pai o te poraka e rua mo te kaha me te iti o te kaha;

8. Ko te punaha whakakii me te punaha whakakii pai te whakarite i te miihini tere mahi, ia poraka 4 ~ 8 meneti;

9.E whakahaerehia ana te mana whakahaere e te hydraulic papu, na reira pana katoa nga korero katoa ka hoki mai ano te tere;

10. Ko nga waahanga e whakamahia ana i roto i te miihini, he kawemai nga hua kua whakauruhia, kua rongonui ranei.

Nga tohu hangarau matua

Take | Aronui | PB2000V | PB3000V | PB4000V | PB6000V | |

Te rahi o te ana | mm | 2040 * 1240 * 1030 | 3060 * 1240 * 1030 | 4080 * 1240 * 1030 | 6100 * 1240 * 1030 | |

Rahi poraka | mm | 2000 * 1200 * 1000 | 3000 * 1200 * 1000 | 4000 * 1200 * 1000 | 6000 * 1200 * 1000 | |

Mamaoa | Kūwaha | Iroiti | 2 '' (DN50) | 2 '' (DN50) | 6 '' (DN150) | 6 '' (DN150) |

Mate kohi-ā-kiko | Kg / huringa | 25 ~ 45 | 45 ~ 65 | 60 ~ 85 | 95 ~ 120 | |

Pēhanga | Mai | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Rangi tuitui | Kūwaha | Iroiti | 1.5 '' (DN40) | 1.5 '' (DN40) | 2 '' (DN50) | 2 '' (DN50) |

Mate kohi-ā-kiko | m³ / huringa | 1.5 ~ 2 | 1.5 ~ 2.5 | 1.8 ~ 2.5 | 2 ~ 3 | |

Pēhanga | Mai | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Te whakamakuku wai | Kūwaha | Iroiti | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) |

Mate kohi-ā-kiko | m³ / huringa | 0.4 | 0.6 | 0.8 | 1 | |

Pēhanga | Mai | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | |

Wāwāhi | Te rerenga rerenga | Iroiti | 4 '' (DN100) | 5 '' (DN125) | 5 '' (DN125) | 6 '' (DN150) |

Heke iho te puku | Iroiti | 4 '' (DN100) | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | |

Hau whakamahana hau | Iroiti | 4 '' (DN100) | 4 '' (DN100) | 6 '' (DN150) | 6 '' (DN150) | |

Te kaha 15kg / m³ | Min / huringa | 4 | 5 | 7 | 8 | |

Tūhono uta / Mana | Kw | 19.75 | 23.75 | 24.5 | 32.25 | |

Whānui te rahi (L * h * w) | mm | 5700 * 4000 * 2800 | 7200 * 4500 * 3000 | 11000 * 4500 * 3000 | 12600 * 4500 * 3100 | |

Taumaha | Kg | 5000 | 6500 | 10000 | 14000 | |

Kēhi

Ataata e pa ana

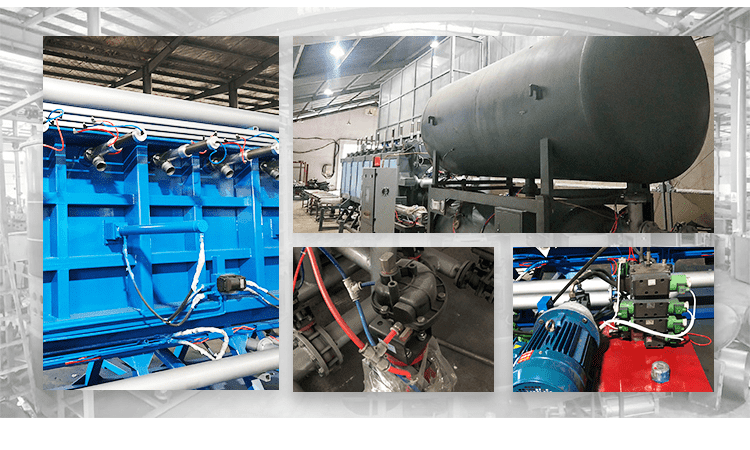

As an Eps Ejector Manufacturer, our machine's design incorporates a vacuum system, ensuring precise moulding of EPS blocks. This feature provides remarkable savings in terms of time and energy, contributing to an eco-friendly manufacturing process. Our product is not just about making EPS blocks; it's about delivering quality, efficiency, and sustainability in every block produced. At DongShen, we understand the needs of the industry. Our commitment as an Eps Ejector Manufacturer goes beyond just delivering machines; we provide full-fledged solutions to assist our clients in enhancing their manufacturing capabilities. By choosing our Polystyrene block moulding machine with vacuum, you choose superior performance, quality, and sustainability. Explore our innovative product range and make a smart choice for your business. Partner with DongShen, your trusted Eps Ejector Manufacturer, to leverage the power of advanced block moulding solutions.