Advanced Styrofoam liquescens apparatus in altum - Efficens Buxing

Product Details

Styrofoam figura CUMATIUM apparatus cum princeps efficientiam ad buxum habet agentibus vacuo ratio, ieiunium hydraulica ratio et ieiunium INCILE ratio. Nam idem productum, cycle tempore in E type apparatus est XXV% brevior quam in normalis apparatus, et industria consummatio est XXV% minus.

Styrofoam figura CUMATIUM Apparatus cum princeps efficientiam ad buxum complet cum plc, tactus screen, implens ratio, agentibus vacuo ratio, hydraulica ratio, electrica arca

Principalis features

Machina laminis fiunt de crassius ferro laminas ita suus diu perpetuam;

Machina habet agentibus vacuo ratio, vacuum lacus et condenser piscinam separatum;

Machina uti ieiunium hydrau ratio, salvis fingunt claudendo et foramen tempus;

Alia impletiones modi sunt praesto vitare impletionem forsit in speciali products;

Machina utitur magnus pipe ratio, permittens humilis pressura fumantia. III ~ 4BBAR vapor potest operari machina;

Machina vapor pressura et penetratio fumantemque regitur per German pressura manometer et pressura regulators;

Components in apparatus sunt maxime importari et celebre notata products, humilis malfunction;

Machina cum elevatis crura, ita client solum opus ad simplex opus suggestum ad operarios.

Main Technical parametri

| Item | Unitas | Faust1200e | Faid1400e | Faid1600e | Faf1850e | |

| PRAETERITUS | mm | MCC * M | MCD * MCC | MDC * MCCCL | MDCCL * MCDL | |

| Max productum dimensionem | mm | M * DCCC * CD | MCC * M * CD | MCL MCL * CD | MDL * MCCL * CD | |

| Plaga | mm | CL ~ MD | CL ~ MD | CL ~ MD | CL ~ MD | |

| Vapor | Ingressio | Inch | III '' (DN80) | IV '' (DN100) | IV '' (DN100) | IV '' (DN100) |

| Consummatio | Kg / exolvuntur | IV ~ VII | V IX IX | VI ~ X | VI ~ XI | |

| Pressura | MPA | 0,4 ~ 0.6 | 0,4 ~ 0.6 | 0,4 ~ 0.6 | 0,4 ~ 0.6 | |

| Refrigerandum aquae | Ingressio | Inch | 2.5 '' (DN65) | III '' (DN80) | III '' (DN80) | III '' (DN80) |

| Consummatio | Kg / exolvuntur | XXV ~ LXXX | XC ~ XC | XXXV ~ C | XXXV ~ C | |

| Pressura | MPA | 0,3 ~ 0.5 | 0,3 ~ 0.5 | 0,3 ~ 0.5 | 0,3 ~ 0.5 | |

| Compressum aere | Humilis pressura ingressum | Inch | II '' (DN50) | 2.5 '' (DN65) | 2.5 '' (DN65) | 2.5 '' (DN65) |

| Humilis pressura | MPA | 0,4 | 0,4 | 0,4 | 0,4 | |

| Princeps pressura ingressum | Inch | I '' (DN25) | I '' (DN25) | I '' (DN25) | I '' (DN25) | |

| Pressura | MPA | 0,6 ~ 0.8 | 0,6 ~ 0.8 | 0,6 ~ 0.8 | 0,6 ~ 0.8 | |

| Consummatio | M³ / Cycle | 1.5 | 1.8 | 1.9 | 2 | |

| Drainage | Inch | V '' (DN125) | VI '' (DN150) | VI '' (DN150) | VI '' (DN150) | |

| Capacio15kg / M³ | S | LX ~ CX | LX ~ CXX | LX ~ CXX | LX ~ CXX | |

| Iungo Lond / Power | Kw | 9 | 12,5 | 14.5 | 16.5 | |

| Altiore dimensionem (L * w * h) | mm | (IV) DCC * MM * (IV) DCLX | (IV) DCC * MMCCL * (IV) DCLX | (IV) DCCC * MMDXXX (IV) DCXC | (V) LXXX * MMDCCCLXXX * (IV) DCCXC | |

| Pondus | Kg | (V) D | (VI) | (VI) D | (VII) | |

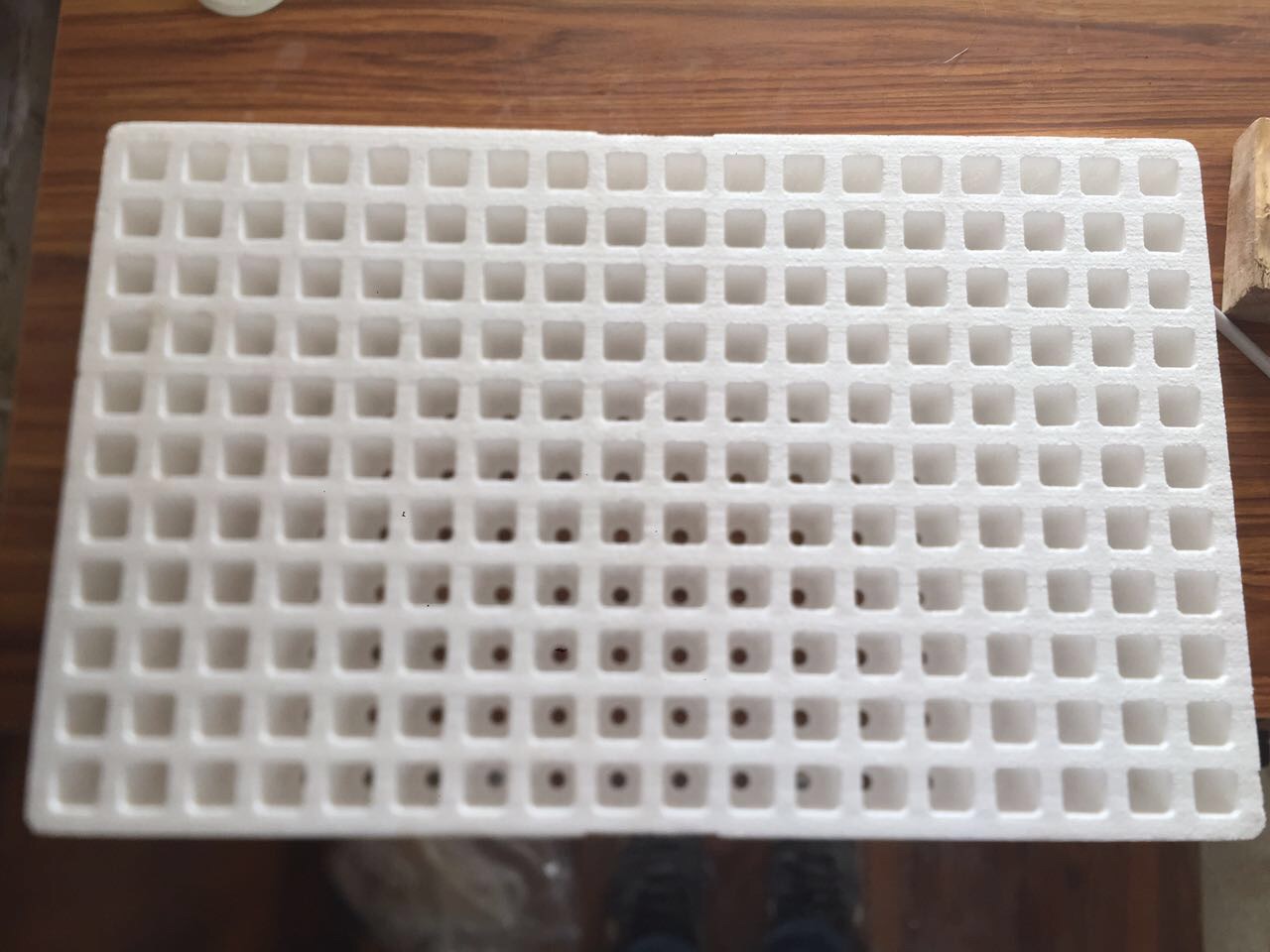

Casus

Related Video

The machine's fast hydraulic system enables seamless operation, reducing manual effort while augmenting productivity. Further, its quick drainage system ensures that the machine maintains its efficiency levels, ultimately improving the overall production rate. By integrating the Styrofoam Melting Machine into your manufacturing line, you can leverage the benefits of a high-performance, energy-efficient and cost-effective solution for your Styrofoam moulding needs. At Dongshen, we understand the importance of efficiency and reliability in manufacturing processes. Our Styrofoam Melting Machine offers you a solution that combines these essentials, empowering your business to deliver superior quality while enhancing production efficiency.