Solusi Molding BLOK EP Superior saka Produsen EPS Ejek Ekskata, DONGSHEN

Rincian Produk

Mesin cetakan blok polistikrene kanthi vakum minangka mesin ePS sing efisien nggawe blok EPS. Blok EPS bisa dipotong kanggo lembaran kanggo insulasi omah utawa kemasan. Produk sing populer digawe saka lembaran eps yaiku panel Sandwich EPS, panel 3D, panel inner tembok njaba, kemasan kaca, packing perabot lsp.

Mesin cetakan blok polistikrene kanthi vakum bisa ngasilake blok kapadhetan EPS sing dhuwur, makarya kanthi cepet, lan kabeh blok sing langsung lan kuwat lan kelembapan banyu sing kurang. Mesin kasebut uga bisa nggawe blok kapadhetan kanthi kualitas apik. Bisa nggawe kapadhetan sing dhuwur ing 40g / l lan kurang kapadhetan ing 4G / L.

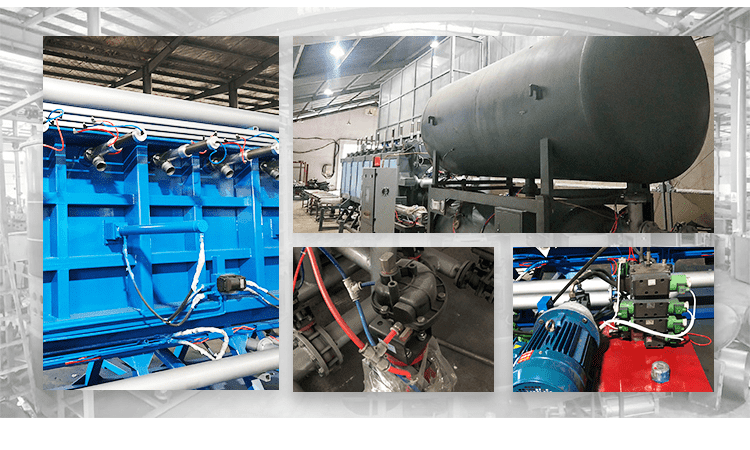

Mesin cetakan blok polistikrene kanthi vakum lengkap karo awak mesin utama, kothak kontrol, sistem vakum, sistem timbang lsp.

Mesin cetakan blok polistirena kanthi kaluwihan vakum:

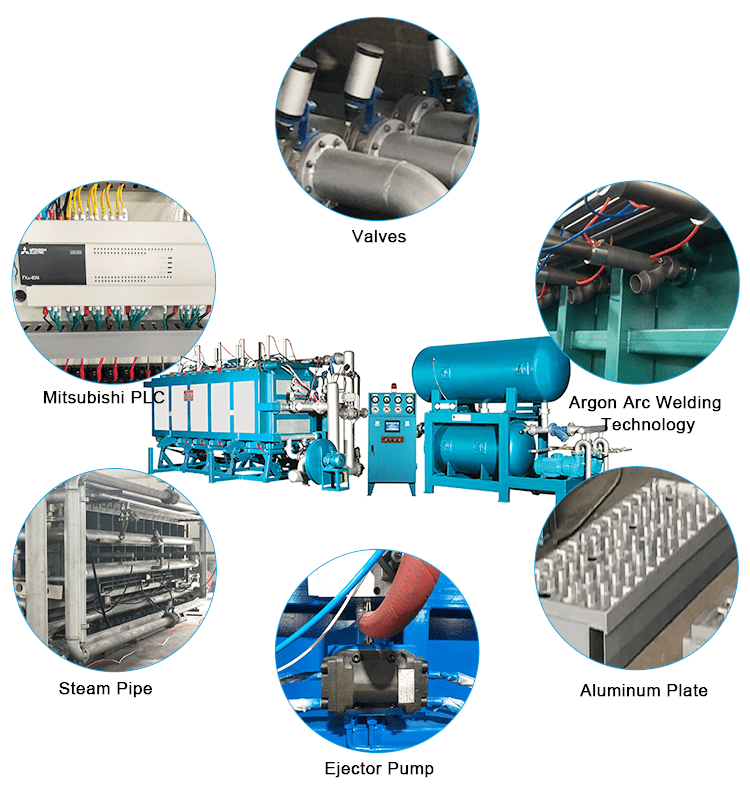

1.Machine digawe saka tabung alun-alun lan piring baja tebal;

2.Machine nggunakake piring kukus aluminium aluminium kanthi 5mm kanthi lapisan teflon. Lan ing piring aluminium, dhukungan ukuran sing luwih gedhe kanthi luwih akeh diselehake kanggo nyegah cacat piring aluminium ing tekanan sing dhuwur. Piring aluminium ora'T Ganti wujud sawise sepuluh taun kerja;

3.Machine'S kabeh enem panel yaiku liwat perawatan panas kanggo ngeculake stres welding, supaya panel ora bisa cacat kanthi suhu sing dhuwur;

4.Machine kanthi garis uap liyane kanggo njamin steaming sanajan ing blok, saéngga blok blokir luwih apik;

Plat-piring 5.machine minangka sistem got saluran sing luwih apik supaya blokir luwih garing lan bisa dipotong kanthi cendhak;

6.Aliwat piring mesin liwat gangguan bal, banjur nyemprotake bal, banjur DOT - Anti - Lukisan Dasar Anti - Anti - Lukisan Lukisan, saéngga awak mesin ora gampang dirasakake;

7.Machine Gunakake sistem pipo lan proses steaming, njamin blok blok loro kanthi kapadhetan lan kapadhetan sing kurang;

8.Fast sistem ngisi lan sistem vakum sing efisien njamin mesin cepet kanthi cepet, saben blok 4 ~ 8 menit;

9.Sebut dikontrol dening pompa hidrolik, saengga kabeh ejectors nyurung lan ngasilake kacepetan sing padha;

Komponisi 10.Mom sing digunakake ing mesin kasebut diimpor utawa produk muni sing misuwur.

Paramèter teknis utama

Item | Unit | PB2000V | PB3000V | PB4000V | PB6000V | |

Ukuran rongga mold | mm | 2040 * 1240 * 1030 | 3060 * 1240 * 1030 | 4080 * 1240 * 1030 | 6100 * 1240 * 1030 | |

Ukuran Blok | mm | 2000 * 1200 * 1000 | 3000 * 1200 * 1000 | 4000 * 1200 * 1000 | 6000 * 1200 * 1000 | |

Uap | Entri | Inci | 2 '' (DN50) | 2 '' (DN50) | 6 '' (DN150) | 6 '' (DN150) |

Konsumsi | Kg / siklus | 25 ~ 45 | 45 ~ 65 | 60 ~ 85 | 95 ~ 120 | |

Meksa | MPA | 0,6 ~ 0.8 | 0,6 ~ 0.8 | 0,6 ~ 0.8 | 0,6 ~ 0.8 | |

Udhara sing dikompres | Entri | Inci | 1.5 '' (DN40) | 1.5 '' (DN40) | 2 '' (DN50) | 2 '' (DN50) |

Konsumsi | M³ / Siklus | 1,5 ~ 2 | 1,5 ~ 2,5 | 1.8 ~ 2,5 | 2 ~ 3 | |

Meksa | MPA | 0,6 ~ 0.8 | 0,6 ~ 0.8 | 0,6 ~ 0.8 | 0,6 ~ 0.8 | |

Banyu pendinginan vakum | Entri | Inci | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) |

Konsumsi | M³ / Siklus | 0,4 | 0,6 | 0,8 | 1 | |

Meksa | MPA | 0,2 ~ 0.4 | 0,2 ~ 0.4 | 0,2 ~ 0.4 | 0,2 ~ 0.4 | |

Saluran | Saluran vakum | Inci | 4 '' (DN100) | 5 '' (DN125) | 5 '' (DN125) | 6 '' (DN150) |

Mudhun bocor uap | Inci | 4 '' (DN100) | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | |

Bolongan hawa udara | Inci | 4 '' (DN100) | 4 '' (DN100) | 6 '' (DN150) | 6 '' (DN150) | |

Kapasitas 15kg / m³ | Min / Siklus | 4 | 5 | 7 | 8 | |

Sambungake Muja / Power | Kw | 19.75 | 23.75 | 24.5 | 325 | |

Ukuran sakabèhé (L * h * w) | mm | 5700 * 4000 * 2800 | 7200 * 4500 * 3000 | 11000 * 4500 * 3000 | 12600 * 4500 * 3100 | |

Bobot | Kg | 5000 | 6500 | 10000 | 14000 | |

Kasus

Video sing gegandhengan

As an Eps Ejector Manufacturer, our machine's design incorporates a vacuum system, ensuring precise moulding of EPS blocks. This feature provides remarkable savings in terms of time and energy, contributing to an eco-friendly manufacturing process. Our product is not just about making EPS blocks; it's about delivering quality, efficiency, and sustainability in every block produced. At DongShen, we understand the needs of the industry. Our commitment as an Eps Ejector Manufacturer goes beyond just delivering machines; we provide full-fledged solutions to assist our clients in enhancing their manufacturing capabilities. By choosing our Polystyrene block moulding machine with vacuum, you choose superior performance, quality, and sustainability. Explore our innovative product range and make a smart choice for your business. Partner with DongShen, your trusted Eps Ejector Manufacturer, to leverage the power of advanced block moulding solutions.