Optimalake kemasan nganggo mesin pemotong Elektronik Electric Molding EPS

Rincian Produk

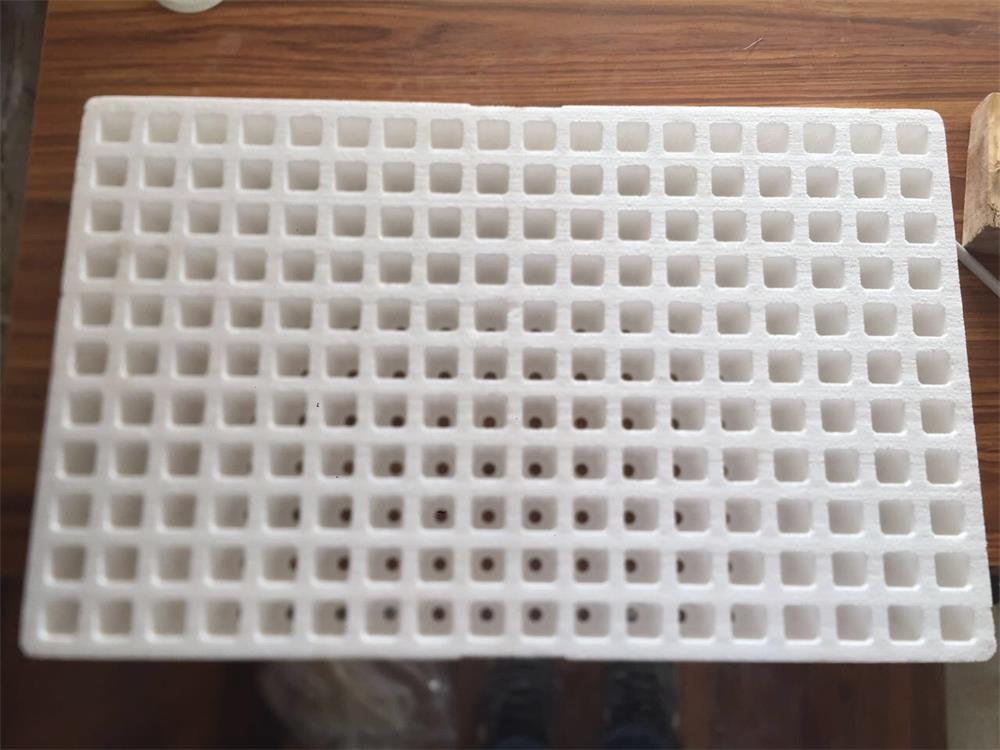

Mesin kemasan polistirena sing ditambahi bebarengan karo jamur kanggo ngasilake produk kemasan kaya ngemut listrik, sayur-kothak lan kothak konstruksi lan sapiturute karo cetakan bata lan sapiturute kanthi cetakan bata lan.

Mesin Ngirit Tenaga Angkat Mesin duwe sistem vakum sing efisien, sistem hidraulik cepet, lan sistem got cepet. Kanggo produk sing padha, wektu siklus ing mesin jinis E 25% luwih cendhek tinimbang mesin normal, lan konsumsi energi 25% kurang.

Mesin ngrampungake karo Plc, layar tutul, sistem ngisi, sistem vakum sing efisien, sistem hidrolik, kothak listrik

Fav1200e - 1750e Mesin kemasan polistirena (efisiensi dhuwur)

Fitur Utama

Wigati dicipta digawe saka piring baja sing luwih thicker saengga saya suwe;

2.Machine duwe sistem vakum sing efisien, tank vakum lan tank tank dipisah;

3.Machine nggunakake sistem hidraulik kanthi cepet, ngirit mold nutup lan mbukak wektu;

4. Cara ngisi cara kasedhiya kanggo ngindhari masalah kanggo produk khusus;

5.Machine nggunakake sistem pipa gedhe, saéngga kukus tekanan rendah. 3 ~ 4bar uap bisa nggarap mesin;

6.Machine tekanan uap lan steaming nembus dikontrol dening tekanan tekanan Jerman lan pengatur tekanan Jerman;

7.COMPONEN digunakake ing mesin biasane diimpor lan produk muni sing misuwur, cacat kurang;

8.Machine kanthi sikil ngangkat, saéngga klien mung kudu nggawe platform kerja sing gampang kanggo para pekerja.

Paramèter teknis utama

| Item | Unit | Fav1200e | FAV1400E | FAV1600E | Fav150e | |

| Ukuran cetakan | mm | 1200 * 1000 | 1400 * 1200 | 1600 * 1350 | 1750 * 1450 | |

| Ukuran Produk Max | mm | 1000 * 800 * 400 | 1200 * 1000 * 400 | 1400 * 1150 * 400 | 1550 * 1250 * 400 | |

| Stroke | mm | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | |

| Uap | Entri | Inci | 3 '' (DN80) | 4 '' (DN100) | 4 '' (DN100) | 4 '' (DN100) |

| Konsumsi | Kg / siklus | 4 ~ 7 | 5 ~ 9 | 6 ~ 10 | 6 ~ 11 | |

| Meksa | MPA | 0,4 ~ 0,6 | 0,4 ~ 0,6 | 0,4 ~ 0,6 | 0,4 ~ 0,6 | |

| Banyu pendinginan | Entri | Inci | 2.5 '' (DN65) | 3 '' (DN80) | 3 '' (DN80) | 3 '' (DN80) |

| Konsumsi | Kg / siklus | 25 ~ 80 | 30 ~ 90 | 35 ~ 100 | 35 ~ 100 | |

| Meksa | MPA | 0,3 ~ 0.5 | 0,3 ~ 0.5 | 0,3 ~ 0.5 | 0,3 ~ 0.5 | |

| Udhara sing dikompres | Entri tekanan rendah | Inci | 2 '' (DN50) | 2.5 '' (DN65) | 2.5 '' (DN65) | 2.5 '' (DN65) |

| Tekanan sithik | MPA | 0,4 | 0,4 | 0,4 | 0,4 | |

| Entri tekanan tinggi | Inci | 1 '' (dn25) | 1 '' (dn25) | 1 '' (dn25) | 1 '' (dn25) | |

| Meksa dhuwur | MPA | 0,6 ~ 0.8 | 0,6 ~ 0.8 | 0,6 ~ 0.8 | 0,6 ~ 0.8 | |

| Konsumsi | M³ / Siklus | 1.5 | 1.8 | 1.9 | 2 | |

| Saluran | Inci | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | 6 '' (DN150) | |

| Kapasitas15kg / m³ | S | 60 ~ 110 | 60 ~ 120 | 60 ~ 120 | 60 ~ 120 | |

| Sambungake Muja / Power | Kw | 9 | 12.5 | 14,5 | 16.5 | |

| Ukuran sakabèhé (l * w * h) | mm | 4700 * 2000 * 4660 | 4700 * 2250 * 4660 | 4800 * 2530 * 4690 | 5080 * 2880 * 4790 | |

| Bobot | Kg | 5500 | 6000 | 6500 | 7000 | |

Kasus

Video sing gegandhengan

The combination of our comprehensive technology, the Electric Styrofoam Foam Cutter, and your vision, can transform ordinary packaging into a value-added element of your product. Whether you're aiming to enhance product protection, improve aesthetic appeal, or increase branding potential, this machine delivers on all fronts. With DongShen's Electric Styrofoam Foam Cutter, you're investing in a machine that guarantees precision, quality, and innovative packaging solutions. Leverage this technology to stand out in your market and deliver products that are professionally packaged, ensuring maximum protection and appeal. Invest in our Electric Styrofoam Foam Cutter today and elevate your packaging process.