2020 wholesale price Eps Raw Material Reactor - EPS Raw Material Project – DONGSHEN

2020 wholesale price Eps Raw Material Reactor - EPS Raw Material Project – DONGSHENDetail:

Summary of EPS(Expandable PolyStyrene) raw material production

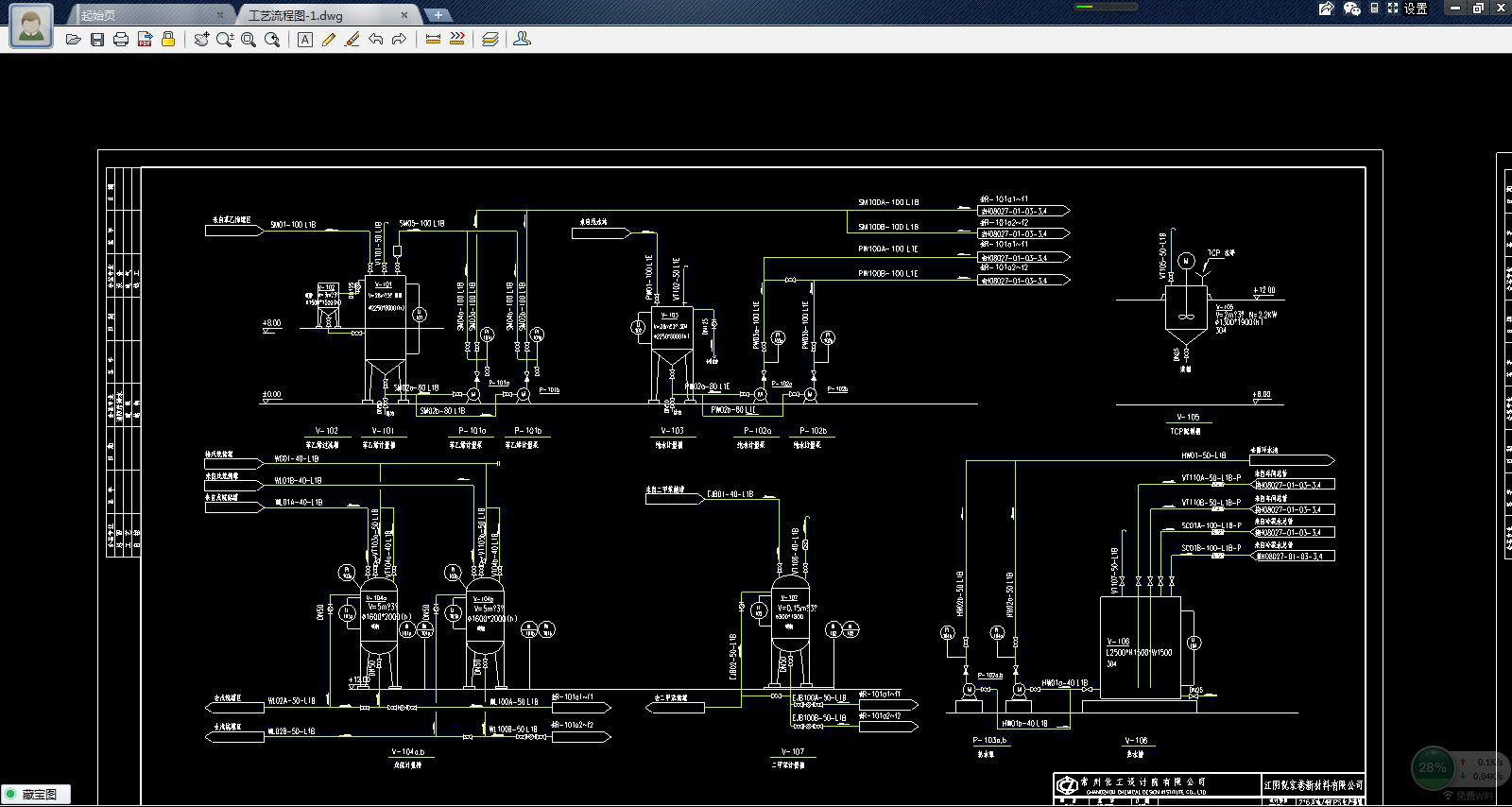

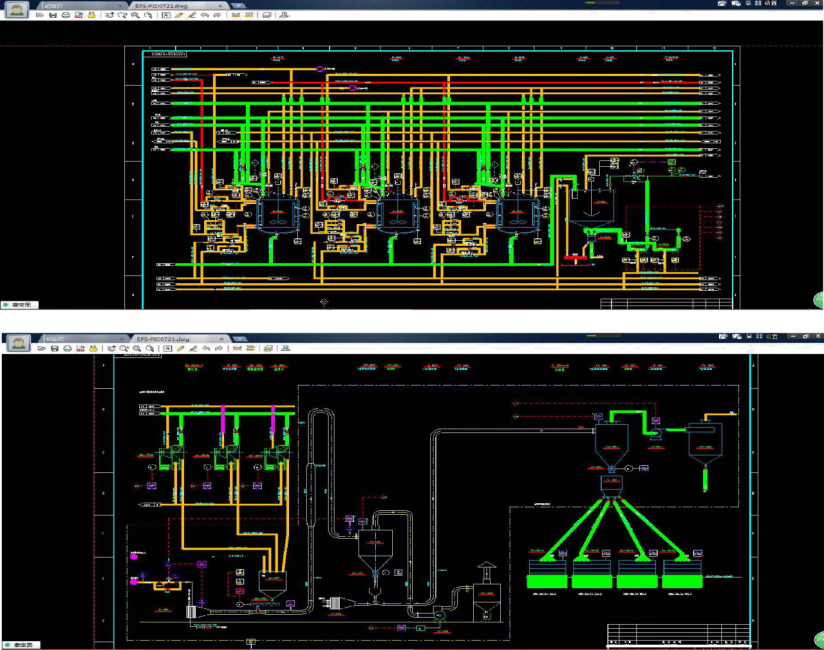

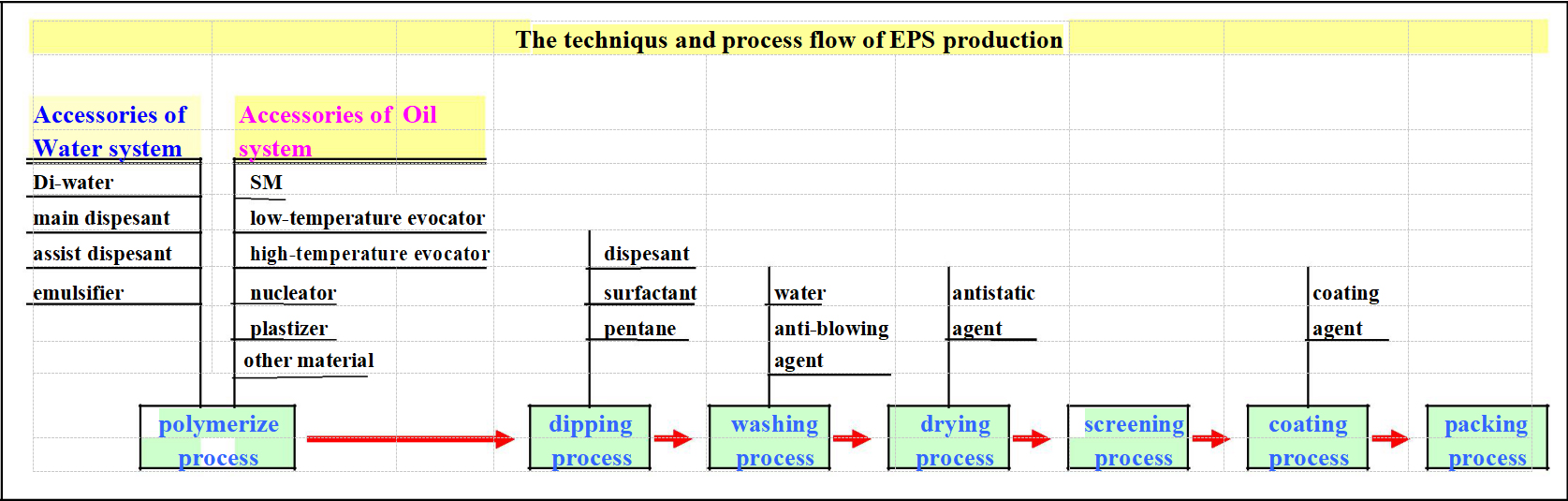

Process Flow introduction

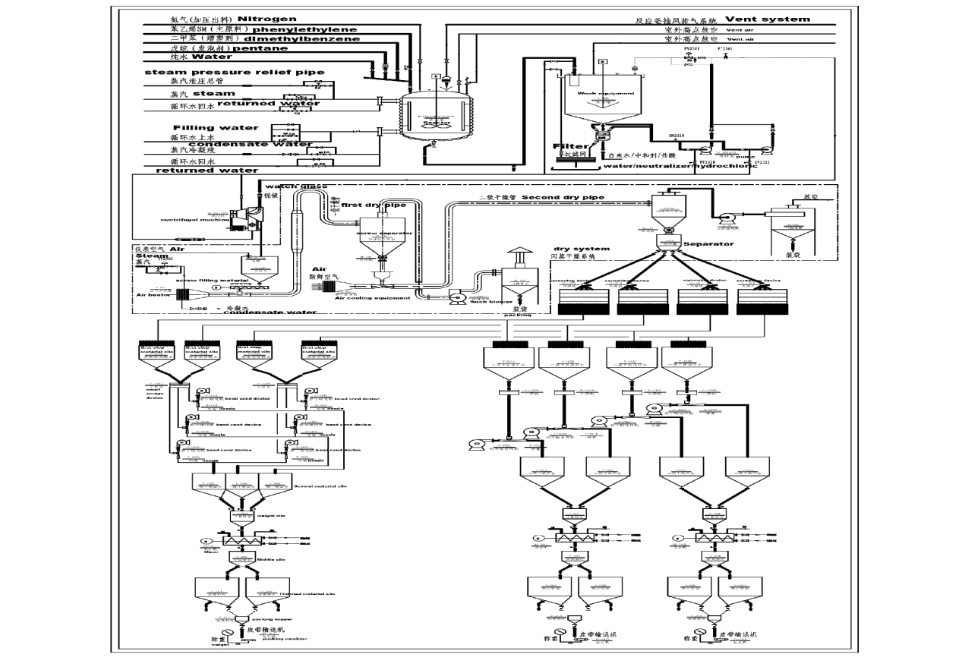

Proses siji - Cara langkah kalebu polimerisasi, impreganisasi, pendinginan, ngumbah, pangatusan, peringatan, lapisan, lapisan, geter. Rata-rata siklus produksi produksi eps yaiku 16 ~ 17 jam.

(1) Polymerization and Impregnation

Polymerisasi lan impregnasi sing diwenehake ing reaktor. Ing santun tartamtu, SM bakal polimerize. Dening communy shiring, SM bakal ditambahi lan dipotong, banjur nyipta tetes minyak silat sing ditundha ing banyu amarga tekanan lumahing. Ana baturon sing nundha ing banyu supaya bisa narik partikel bump lan sambung bebarengan. Ing proses iki, kekuwatan disires kudu luwih gedhe tinimbang kekuwatan nyambung kanggo njamin rendah -

Reaksi polimerisasi sing kurang - mlaku ing tetes minyak SM, Panas dibebasake ing reaksi kasebut bakal dijupuk kanthi banyu pendinginan ing disetel ing klip. Kanggo mbusak panas ing wektu, kita kudu njamin sistem banyu daur ulang sajrone proses reaksi sajrone proses reaksi. Yen ora, suhu ing reaktor bakal dhuwur banget, sing nyebabake reaksi cepet lan viskositas sing luwih dhuwur.

Proses produksi manik dikontrol kanthi manual, sajrone proses, suhu kudu dikontrol kanthi tepat kanggo ngindhari fluktuasi sing gedhe, yen ora, ukuran manik-manik bakal digedhekake. Temenan, asring pengamatan conto penting kanggo ngontrol ukuran manik-manik.

By the adjust of light weight CaCO3 and TCP, the size of beads can be controlled.

Sistem DCS digunakake kanggo kontrol suhu sajrone proses pemanasan, polimerisasi, impregnation, dhuwur - reaksi suhu, lan pendinginan. Kanggo njamin produksi safety, sistem DCS bakal ngontrol panyiksa reaksi lan wektu, lan alarm ing ndhuwur - suhu utawa overpressure.

Nalika tingkat konversi SMAT udakara 75% (udakara 4 nganti 5 jam ing suhu sing tetep), jumlah tartamtu saka agen jotosan kudu ditambahake. Sawise impregnating lan polimerisasi ing wektu lan tekanan tartamtu, kita bisa entuk manik EPS.

Agen ngunekke kanggo impregnasi disuntikake dadi ngukur ceret kanthi pompa, lan kanthi akurat kanthi piranti streighting. Sawise ing dhuwur - proses templatature, nalika adhem ing suhu sing ditemtokake, materi bisa dibuwang menyang tank cuci.

(2) Washing

The impurities such as dispersant and defloculates must be removed by washing. After cleaning, the EPS beads will be dried by centrifugal dehydration to remove most surface water, and ready for further drying.

We can also use de-foaming agent to remove impurities.

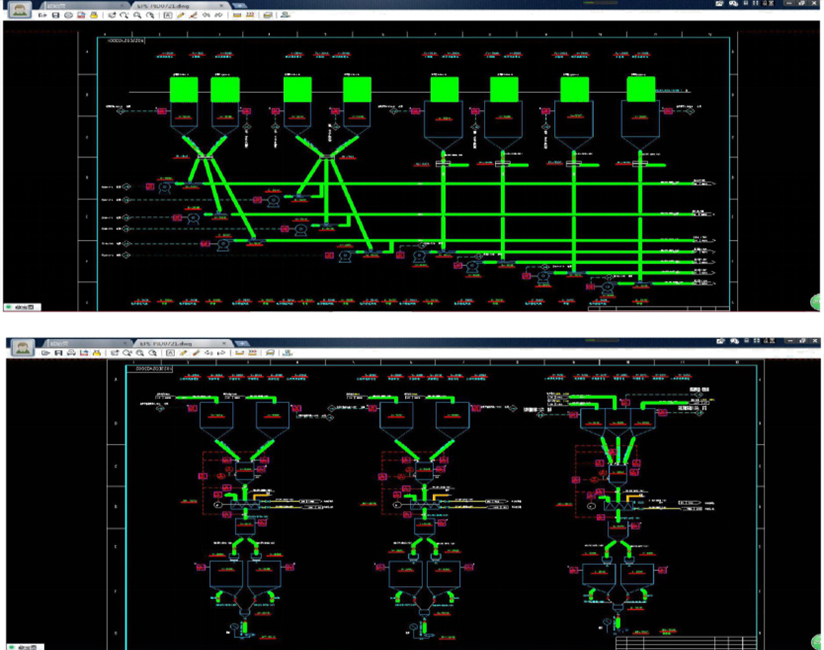

(3) Drying

Sawise dehidrasi sentrifugal, ana udakara 3% sisa-sisa manik-manik (konten banyu sing dhuwur bakal pengaruhe kualitas produk EPS), dadi proses pangatusan luwih garing. Ngunekke angin panas, banyu penduduk lumahing dadi kukus, mula kaya bensin sing ana ing tengah-tengah Sillone, lan nyepetake udara sing dhuwur, lan nyepetake hawa sing dhuwur - Kanthi cara iki, manik bakal garing.

Sawise pangatusan hawa panas, manik-manik kudu adhem dening angin adhem supaya bisa nyuda isi banyu, lan siyap screening. Kanggo nyegah klumpukan listrik, agen antisatik kudu ditambahake sajrone pangatusan.

The drying temperature is controlled by DCS system.

(4) Screening

The sizes of dried EPS beads are uneven, screening maching is needed to separate the beads by specification and transfer to different silos.

(5) Coating

Sajrone produksi EPS, panyimpenan, transportasi lan proses, luput agen bledosan ora bisa dielingi. Yen agen bledug kakehan ilang, akeh masalah sing bakal kedadeyan, kayata nyuda tingkat sing berkembang, nambah kapercayan, lan sapiturute kanggo nglamar agen panyebaran, panggunaan agen lapisan ing permukaan EPS penting.

(6) Package

Package the EPS beads according to different specification. The standard package weight is 25kg.

Purpose of packaging : conenience transportation, avoid the escape of blowing agent, and extend the guarantee period.

EPS Flow Chart

Case

Product detail pictures:

Related Product Guide:

Kita mesthi percaya yen karakter siji kasebut nemtokake kualitas produk, rincian mutusake produk 'kanthi kualitas, bebarengan karo semangat realistis, efisien lan inovatif lan inovatif cemal harga reaktor material ePhter 2012 Proyek bahan mentah EPS - Dongshen, produk kasebut bakal nyediakake ing saindenging jagad, kayata: Peru, Jeddah, Kuwait, item wis ditampa kanthi sertifikasi nasional lan wis ditampa ing industri utama. Tim teknik ahli kita asring siap kanggo ngladeni sampeyan kanggo konsultasi lan umpan balik. Kita uga bisa ngirim sampeyan kanthi biaya - conto gratis kanggo nyukupi spesifikasi sampeyan. Usaha sing cocog bisa uga diprodhuksi kanggo nyedhiyakake layanan lan solusi sing paling migunani. Apa sampeyan kudu kasengsem ing perusahaan lan solusi kita, hubungi kontak karo kita kanthi ngirim email AS utawa langsung nelpon. Supaya bisa ngerti solusi lan perusahaan. Luwih, sampeyan bakal bisa teka ing pabrik kita kanggo ndeleng. Kita bakal terus welcome tamu saka kabeh ndonya kanggo tenan. o mbangun perusahaan bisnis. elasi karo kita. Mangga rumangsa gratis kanggo kita kanggo kita kanggo organisasi. Ya, kita bakal nuduhake pengalaman praktis sing paling apik karo kabeh pedagang kita.