Na-eduzi ndị na-eweta e ji dị elu

EPS na-emeghachi omume

| Paramita | Baa uru |

|---|---|

| Mgwooru | Igwe anaghị agba nchara |

| Ike | Ruo 10,000 l |

| Okpomọnọ | 10 Celsius C - 80 Celsius C |

| Nnukwu nso | 0 - 10 mmanya |

Nkọwapụta ngwaahịa a na-ahụkarị

| Nkowa | Nkowa |

|---|---|

| Ịnye ọkụ | 380V / 50hz |

| Nchedo Nchedo | IP65 |

| Usoro njikwa | PLC sonye |

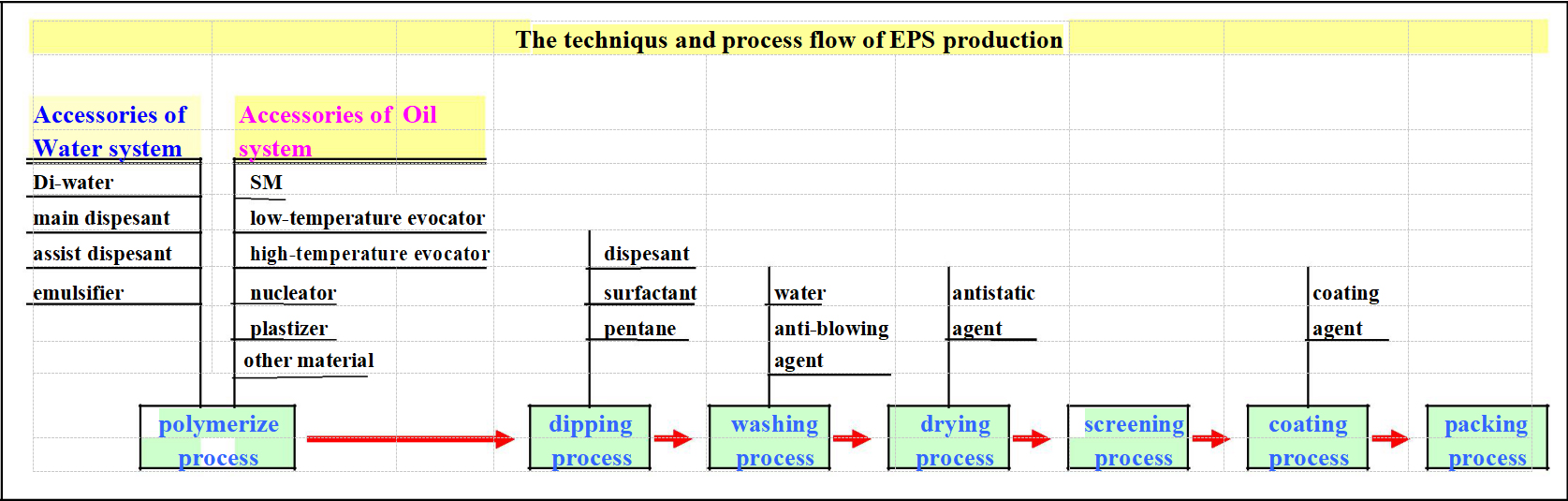

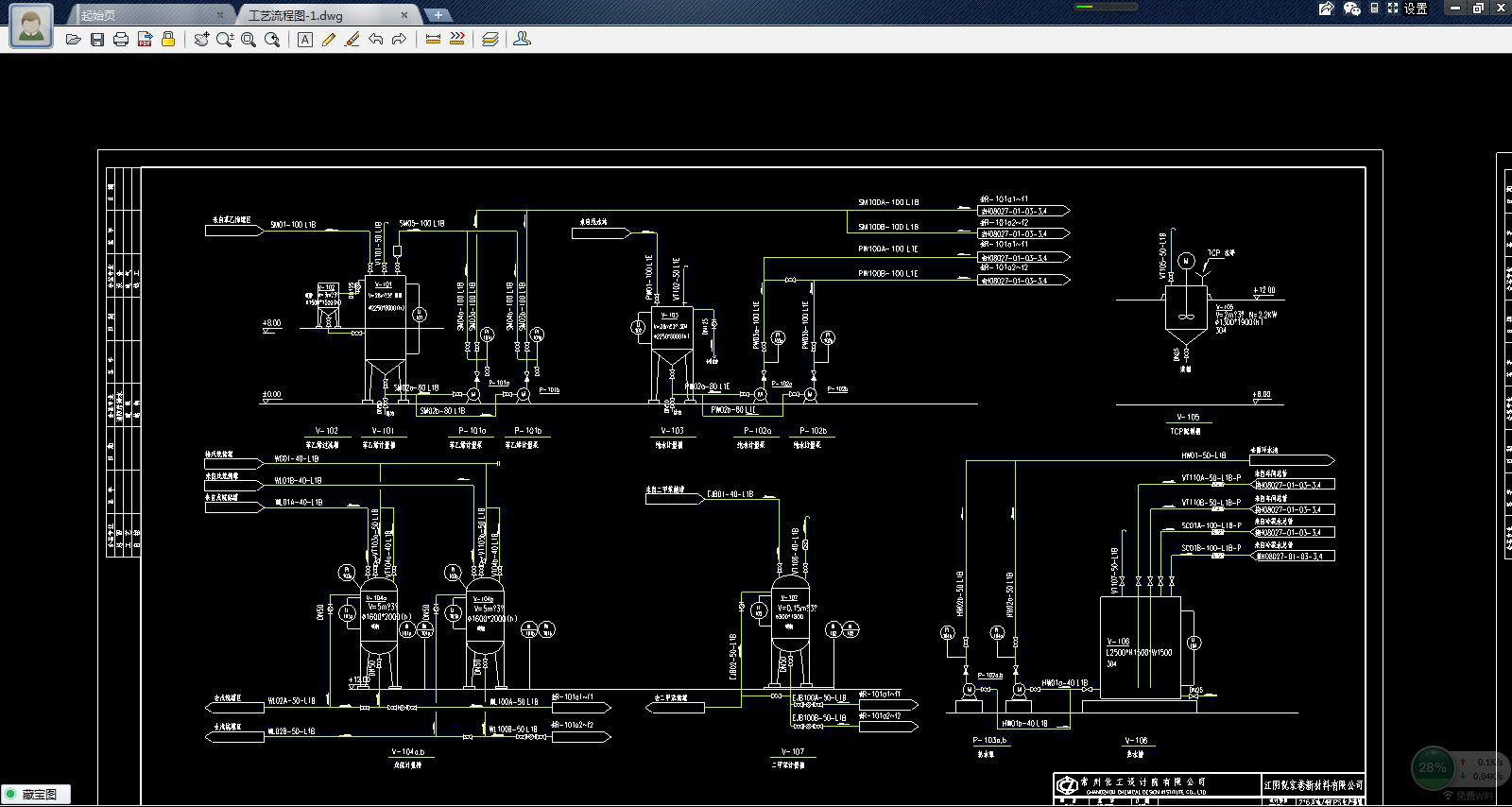

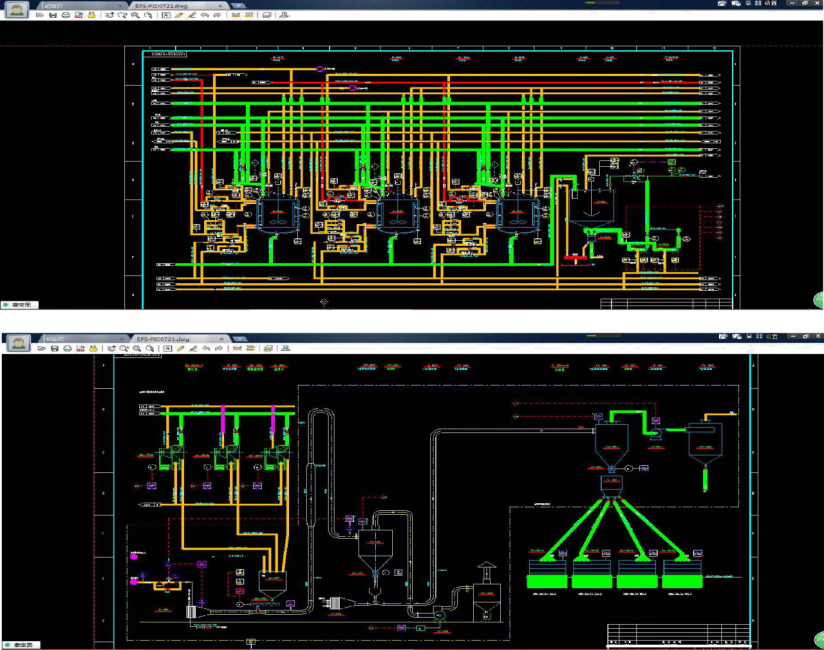

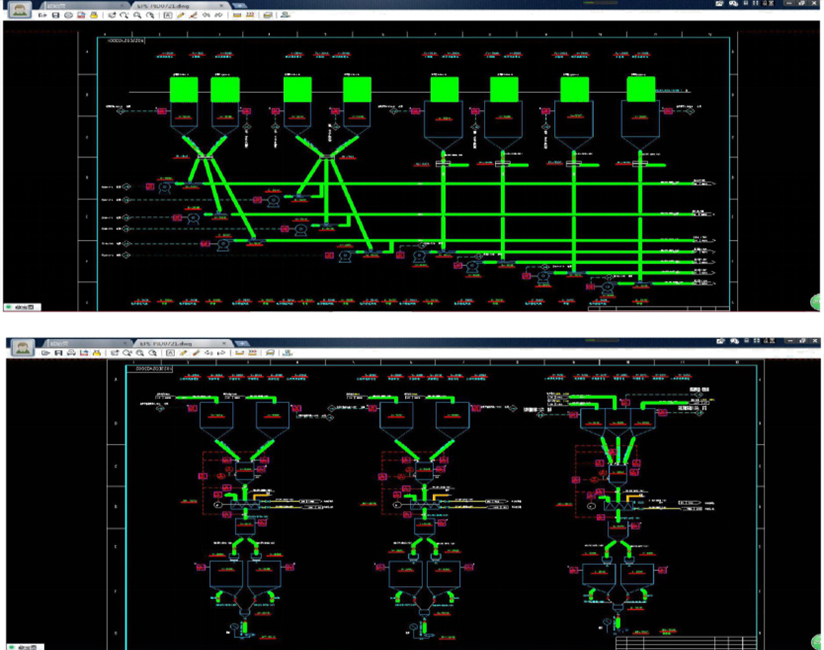

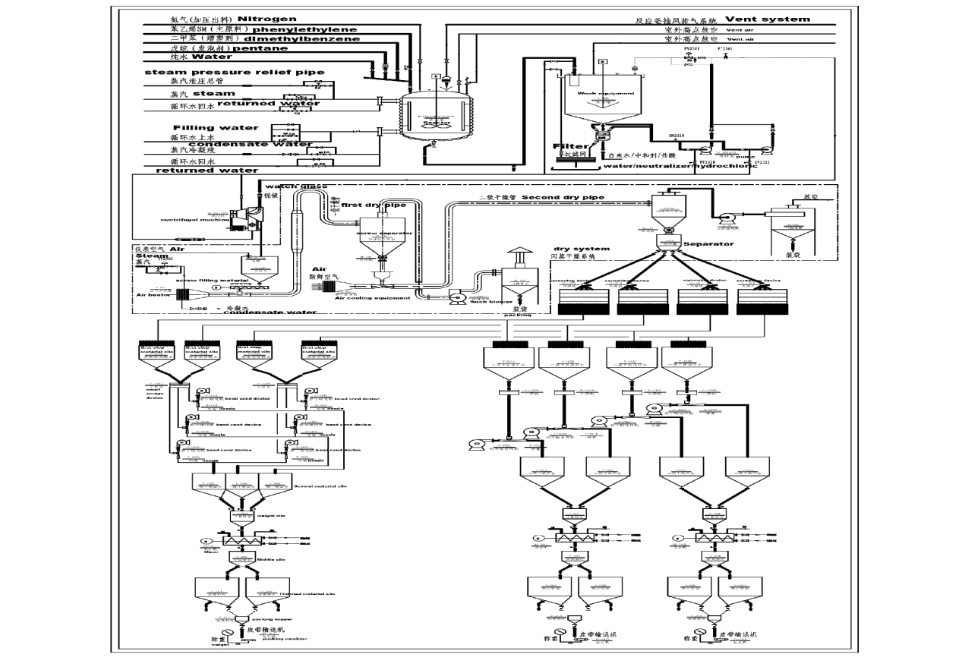

Usoro na-arụpụta usoro nrụpụta

The manufacturing process of EPS Reactors involves precise assembling of stainless steel components, followed by rigorous testing to ensure leak-proof and high-performance systems. Drawing from recent studies, the incorporation of advanced welding techniques and corrosion-resistant materials contribute to enhanced reactor longevity. The design prioritizes ease of maintenance and operational efficiency, minimizing downtime and operational costs. The focus on innovative engineering ensures the EPS Reactor meets high environmental and safety standards, making it an indispensable tool in modern wastewater treatment facilities.

Ọnọdụ ngwaahịa ngwa

EPS Reactors play a pivotal role in various wastewater treatment applications, including municipal and industrial wastewater management. According to recent research, these reactors effectively reduce biochemical oxygen demand (BOD) and chemical oxygen demand (COD) levels, ensuring compliance with regulatory standards. Their adaptability to fluctuating environmental conditions makes them suitable for diverse climatic zones and operational scales—from small local plants to large metropolitan facilities. Such versatility and efficiency underline the importance of EPS Reactors in achieving sustainable wastewater management goals worldwide.

Ngwaahịa mgbe ị na-ere ahịa

Dongshen na-enye ihe zuru oke mgbe ọrụ azụmaahịa, gụnyere nkwado nrụnye, ọzụzụ mmezi, yana enyemaka enyemaka EPS ndị ọrụ EPPM. Nyocha ọrụ na mmelite ahụ na-ahụ maka sistemụ arụmọrụ ọrụ arụmọrụ kachasị elu.

Njem ngwaahịa

Anyị na-ahụ maka nchekwa dị mma na oge nke EPS ndị na-emegharị site na ndị mmekọ na-ewu ewu. A na-ejikọ ụgbọ mmiri ọ bụla iji belata ihe egwu ndị mebiri emebi n'oge transit, na nsuso dị ezigbo mkpa - mmelite nnyefe oge.

Uru Uru

- Arụmọrụ arụmọrụ dị elu na belatara ike oriri

- Delist chepụta ogologo oge - Oge Ọnọdụ

- Ngwa mgbanwe na-agbanwe agbanwe n'ofe otu ụlọ ọrụ

- Steeti - nke - - Art Systems maka arụmọrụ zuru oke

Face ngwaahịa

- Gịnị bụ ihe e ji arụ ọrụ EPP?

Otu EPS na-emegharị bụ BIORCOCor nke eji eme ọgwụgwọ dị na Betteawater, linowbial biofilms na-emega nke ọma ma belata mmetọ.

- Kedu ihe kpatara Họrọ Donghen ka onye na-eweta ego EPS gị?

Dongshen na-enye ọkachamara na-enweghị atụ, na-ebido - teknụzụ dị na mbara, na-eme ka ọ bụrụ onye na-eweta ntụkwasị obi nke EPS ndị na-ebugharị EPLally na ụwa.

- Kedu ka ndị EPS na-emegharị anya na-eme ka mgbanwe ọkụ dị ọkụ?

A na-emegharị ihe ndị anyị na-arụ ọrụ ka ọ nọgide na-arụ ọrụ dị mma karịa oke okpomọkụ, na-akwado arụmọrụ na-agbanwe agbanwe na mgbanwe gburugburu.

- Kedu mmezi a chọrọ maka ndị na-ere ahịa EPS?

A na-atụ aro nyocha na nhicha a na-atụ aro iji hụ na arụmọrụ kachasị mma. Dongshen na-enye nduzi na nkwado.

- Enwere ike eps remorsors na-ejikwa elu - Ngwa nrụgide?

Ee, a rụrụ ọrụ ndị na-arụ ọrụ iji guzogide nrụgide dị ukwuu, na-enye ọrụ dị mma maka ịchọrọ ngwa ụlọ ọrụ.

- Ọ ga - ekwe omume ịhazi mkpụrụ ego?

Dongshen na-enye nhọrọ iji nweta ihe ndị a kapịrị ọnụ nke a kapịrị ọnụ, na-ejide EPS na-emegharị ahụ dabara na ntọala dị adị.

- Kedu ka ndị ọrụ EPS si mee ka ihe dị mma dị mma?

Site na iji microbial biofilms, onye na-akparaaka anyị na-eme ka mmebi nke mmebe nke ahịhịa, na-ebute ihe arụpụtara dị ọcha.

- Kedu ihe bụ nchekwa nchekwa nke EPS rerụgharị?

Ndị na-akparị ọrụ anyị gụnyere usoro nchekwa nchekwa zuru oke, dị ka mmechi akpaka na nnọkọ akpaaka, iji gbochie ihe ọghọm arụmọrụ wee hụ na nchekwa ọrụ.

- Kedu ka arụ ọrụ ePorm na-enyocha?

A na-ahụ maka arụmọrụ ya na mbelata nke metrik metrik, dị ka ahụ na cond, ma na-agbanwe agbanwe n'okpuru ọnọdụ akọwapụtara.

- Gịnị na-akwado ọrụ aka na-enye Donghen maka ndị ọrụ EPS?

Anyị na-enye enyemaka teknụzụ 24/7, na-emelite sistemụ usoro, yana nkwado saịtị iji hụ na arụmọrụ arụmọrụ na-aga n'ihu na idozi nsogbu ngwa ngwa.

Isi okwu na-ekpo ọkụ

- Ọhụụ nke Ọgwụ Ahụ: ESPMACS

The potential of EPS Reactors is reshaping the wastewater treatment landscape, offering sustainable and efficient solutions. As environmental regulations tighten globally, the demand for advanced treatment technologies is soaring. EPS Reactors, with their ability to handle varying loads and conditions, are at the forefront of this innovation. Industries and municipalities alike are recognizing their value, leading to a surge in adoption and research. This trend is expected to continue, heralding a new era in sustainable water management.

- EPS na-echegharị: Imeri ihe ịma aka nke njikwa obodo mepere emepe

Ugbo ala na-enweta ihe ịma aka nchịkwa nlekọta njikwa. EPS remoctor na-enye ihe ngwọta siri ike, na-ekwupụta ihe dị iche iche nke obodo iyi mepere emepe obodo. Mmegharị ha na arụmọrụ ha na-eme ka ha dị mma maka gburugburu mepere emepe, ebe oghere na ihe mgbochi ihe mgbochi ndị na-ezughị ezu. Site na onu ogugu obodo mepere emepe, ndị na-emegharị EPS na-anọchi anya usoro dị mkpa n'ịnọgide na-enwe usoro dị iche iche mepere emepe mgbe ebe metụtara gburugburu ebe obibi.

- Hazie EPS Rerldsors maka ụlọ ọrụ - Ọkpụkpụ akọwapụtara

Industries have distinct wastewater treatment requirements. EPS Reactors' customization capabilities allow for tailored solutions that meet specific industrial needs. Whether dealing with high organic loads or specific chemical pollutants, these reactors can be adjusted to optimize performance. This flexibility ensures that industries can maintain compliance without compromising on operational efficiency, marking EPS Reactors as pivotal for industrial environmental strategies.

- Arụmọrụ arụmọrụ site na EPS na-emegharị emegharị

Continual innovation in EPS Reactor technology is enhancing operational efficiencies. Recent advancements have focused on improving energy consumption, throughput, and system integration. These enhancements translate to lower operational costs and increased treatment capacity, making EPS Reactors not only an environmental choice but an economically sound one as well. As innovations continue, these reactors are positioned to become even more integral to cost-effective wastewater treatment solutions.

- EPS Remors na-emepe emepe: Onye na-agbanwe egwuregwu

For developing regions facing water treatment infrastructure limitations, EPS Reactors offer a transformative solution. Their efficiency and low maintenance requirements provide a feasible option for regions with limited resources. Implementing these reactors can significantly improve water quality and public health, showing their potential as a catalyst for change in developing areas. The economic and environmental benefits make EPS Reactors a key player in global water management strategies.

- Mmetụta gburugburu ebe obibi

EPS Reactors have been shown to reduce environmental impact by lowering pollutant levels in treated water. By efficiently managing contaminants, these reactors help to protect aquatic ecosystems and reduce the strain on natural water bodies. This environmentally-friendly approach to wastewater treatment underscores the importance of EPS Reactors in achieving sustainable development goals, aligning industrial processes with environmental conservation efforts.

- Tụnyere EPSMAMS na usoro usoro ọdịnala

EPS Reactors offer significant advantages over traditional wastewater systems. Their ability to operate under varying loads and conditions provides greater flexibility and efficiency. Additionally, the reduced sludge production and enhanced treatment capabilities position EPS Reactors as superior alternatives for modern wastewater challenges. Organizations transitioning to these advanced systems report improved performance and compliance with environmental regulations, highlighting the benefits of adopting EPS technology.

- Imirikiti ndị ọrụ EPS na-arụ ọrụ

Udiri Edication dị oke mkpa na njikwa Waterwater. EPS na-emegharị emegharị na nke a site na ịbawanye arụmọrụ Biflolm na ebe mkpofu. Ihe omume ha na-enye ohere maka nhazi ihe na-edozi ahụ, na-ebelata mkpa ihe ndị ọzọ. Ọrụ a na-eduga na nchekwa ego na obere ụlọ ọrụ gburugburu ebe obibi, na-akwado ya na ebumnuche sara mbara nke njikwa akụ na ụba na arụmọrụ akụ na ụba.

- Ikuku EPs Rejors maka nnukwu - ngwa

Dika Istewater chọrọ mmụba, scalability nke EPS Remockers ghọrọ ezigbo uru. Enwere ike idozi usoro ndị a iji zute nnukwu ozi - mkpa arụmọrụ, na-eme ka ha dịrị mma maka ngwa obodo ma ọ bụ ụlọ ọrụ ụlọ ọrụ. Ikike ịba ụba na-enweghị imebi ihe dị ka ihe na-eme ka ọ dị mma dị ka ihe na-achọ ka ọ bụrụ ihe ịma aka dị ukwuu.

- Usoro mmezi mmeghari ohuru maka ndi oru

Effective maintenance is key to sustaining EPS Reactor performance. Innovations in predictive maintenance technologies are enabling more efficient upkeep, reducing downtime and prolonging system life. These strategies focus on early detection of potential issues, ensuring that reactors continue to operate at peak efficiency. Adopting advanced maintenance practices reflects a commitment to long-term operational success, reinforcing the reliability of EPS Reactors in demanding environments.

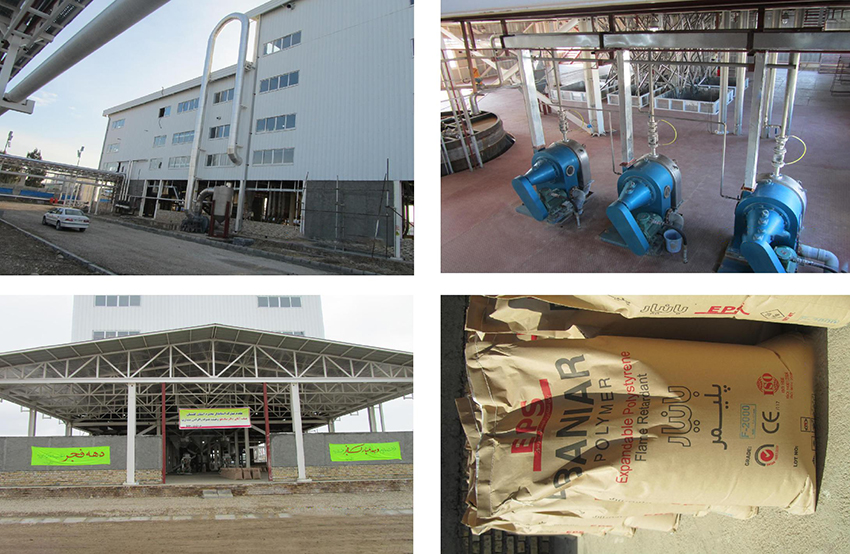

Nkọwapụta Foto