Premium CNC Styrofoam Cutter - Avanse bwat Dongshen a fè solisyon

Detay pwodwi yo

Bwat segondè bon jan kalite styrofoam fè machin gen sistèm vakyòm efikas, sistèm idwolik vit, ak sistèm drenaj vit. Pou pwodwi a menm, tan sik nan machin E kalite se 25% pi kout pase nan machin nòmal, ak konsomasyon enèji se 25% mwens.

High Quality Styrofoam Box fè machin konplete ak PLC, manyen ekran, ranpli sistèm, efikas sistèm vakyòm, sistèm idwolik, bwat elektrik

Karakteristik prensipal

Plak machin yo te fè nan plak asye pi epè konsa li a ki dire lontan;

Machin gen efikas sistèm vakyòm vètikal, tank vakyòm ak tank kondansateur separe;

Machine itilize vit sistèm idwolik, ekonomize fèmen mwazi ak tan ouvèti, lè l sèvi avèk silenn segondè presyon lwil oliv, presyon idwolik 140 - 145bar, vitès idwolik jiska 250mm/s.

Metòd ranpli diferan yo disponib pou fè pou evite ranpli pwoblèm nan pwodwi espesyal, ranpli presyon tounen, ranpli presyon nòmal, ranpli batman kè, presyon depoze elatriye chwa.

Machin sèvi ak gwo sistèm tiyo, sa ki pèmèt ba presyon vapeur. 3 ~ 4bar vapè ka travay machin lan;

Sistèm chofaj machin lan itilize Capteur presyon Alman pou kontwole presyon vapè.

Konpozan yo itilize nan machin nan yo se sitou enpòte ak pi popilè pwodwi make, ki ba fonksyone byen;

Machin ak leve janm, se konsa kliyan sèlman bezwen fè yon senp platfòm k ap travay pou travayè yo.

Machine machin vapè konsomasyon mwens ak travay efikasite pi wo.

Prensipal paramèt teknik

| Sijè | Inite | Fav1200e | FAV1400E | Fav1600e | FAV1750E | |

| Dimansyon mwazi | mm | 1200*1000 | 1400*1200 | 1600*1350 | 1750*1450 | |

| Dimansyon pwodwi max | mm | 1000*800*400 | 1200*1000*400 | 1400*1150*400 | 1550*1250*400 | |

| Tèr | mm | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | |

| Vapè | Antre | Pous | 3 '' (DN80) | 4 '' (DN100) | 4 '' (DN100) | 4 '' (DN100) |

| Konsomasyon | Kg/sik | 4 ~ 7 | 5 ~ 9 | 6 ~ 10 | 6 ~ 11 | |

| Presyon | MPA | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | |

| Refwadisman dlo | Antre | Pous | 2.5 '' (DN65) | 3 '' (DN80) | 3 '' (DN80) | 3 '' (DN80) |

| Konsomasyon | Kg/sik | 25 ~ 80 | 30 ~ 90 | 35 ~ 100 | 35 ~ 100 | |

| Presyon | MPA | 0.3 ~ 0.5 | 0.3 ~ 0.5 | 0.3 ~ 0.5 | 0.3 ~ 0.5 | |

| Lè konprese | Antre presyon ki ba | Pous | 2 '' (DN50) | 2.5 '' (DN65) | 2.5 '' (DN65) | 2.5 '' (DN65) |

| Ba presyon | MPA | 0.4 | 0.4 | 0.4 | 0.4 | |

| Antre presyon segondè | Pous | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | |

| Segondè presyon | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

| Konsomasyon | m³/sik | 1.5 | 1.8 | 1.9 | 2 | |

| Drenaj | Pous | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | 6 '' (DN150) | |

| Kapasite15kg/m³ | S | 60 ~ 110 | 60 ~ 120 | 60 ~ 120 | 60 ~ 120 | |

| Konekte chaj/pouvwa | Kw | 9 | 12.5 | 14.5 | 16.5 | |

| An jeneral dimansyon (l*w*h) | mm | 4700*2000*4660 | 4700*2250*4660 | 4800*2530*4690 | 5080*2880*4790 | |

| Pwa | Kg | 5500 | 6000 | 6500 | 7000 | |

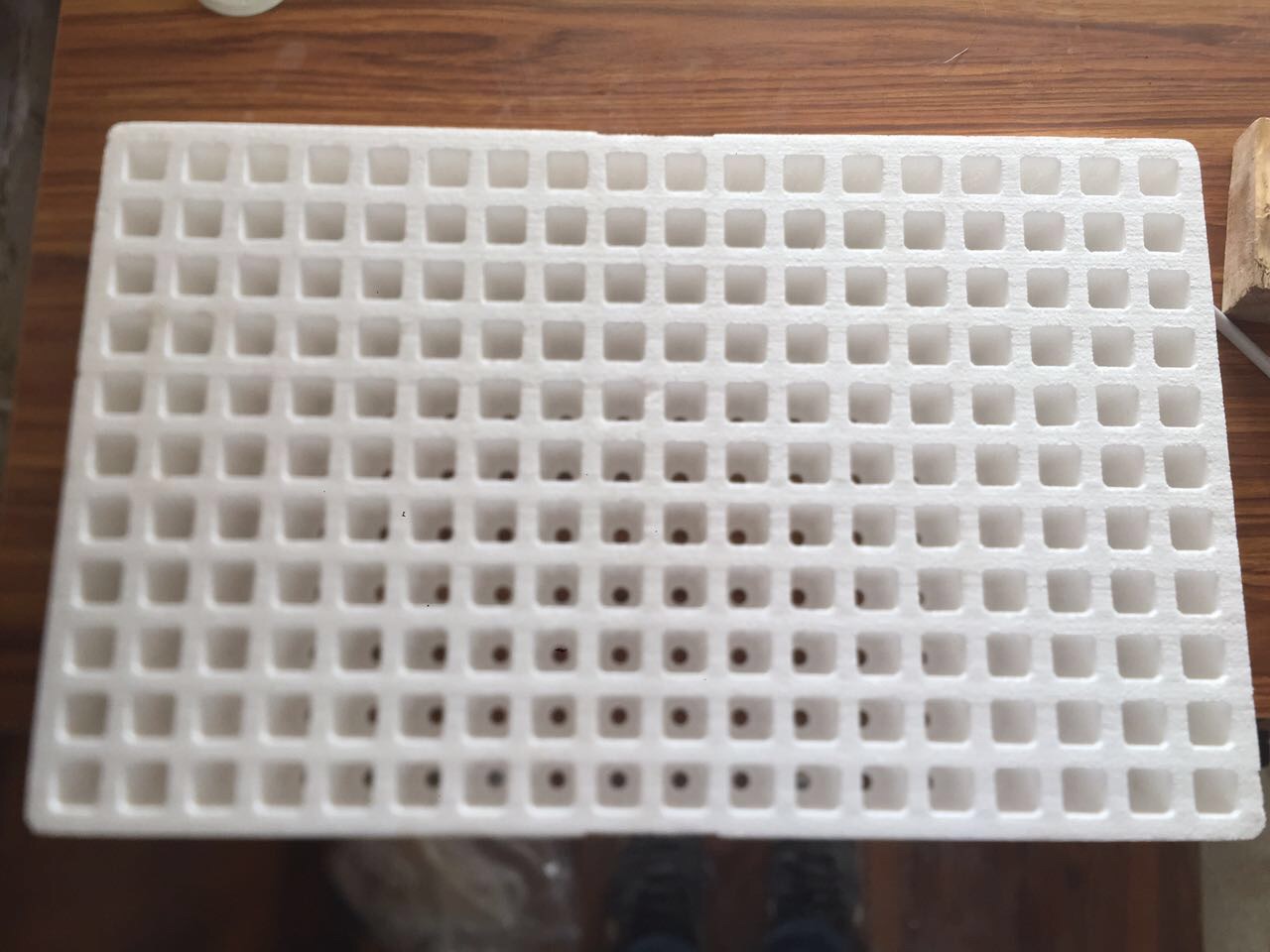

Ka

Videyo ki gen rapò

Every component of our CNC Styrofoam Cutter is made to ensure longevity. Its rapid hydraulic system allows for a smooth and reliable operation, while the efficient vacuum system ensures clean and precise cuts every time. Moreover, the machine's quick drainage capabilities make it ideal for businesses looking to reduce downtime and increase productivity. Choosing Dongshen's CNC Styrofoam Cutter is an investment in quality, speed, and efficiency. Our dedicated team is always ready to provide technical support to ensure that your machine runs without a hitch, prolonging its lifespan and providing excellent value for money. Transform your packaging process with the superior capabilities of our CNC Styrofoam Cutter, and give your business the competitive edge it needs.