Segondè - Efikasite elektrik cho fil kim kouto - Polystyrène blòk bòdi machin

Detay pwodwi yo

Polystyrène blòk machin bòdi ak vakyòm se yon machin EPS efikas fè blòk EPS. Blòk EPS ka koupe nan fèy papye pou izolasyon kay oswa anbalaj. Pwodwi popilè yo te fè soti nan fèy papye EPS yo se panno sandwich EPS, panno 3D, anndan ak deyò panno izolasyon miray, anbalaj vè, anbalaj mèb elatriye.

Polystyrène blòk bòdi machin ak vakyòm ka pwodwi segondè dansite EPS blòk, k ap travay nan sik vit, ak tout blòk yo dwat epi fò ak ak imidite dlo ki ba. Machin nan kapab tou fè blòk dansite ki ba ak bon jan kalite bon. Li ka fè dansite segondè nan 40g/L ak dansite ki ba nan 4G/L.

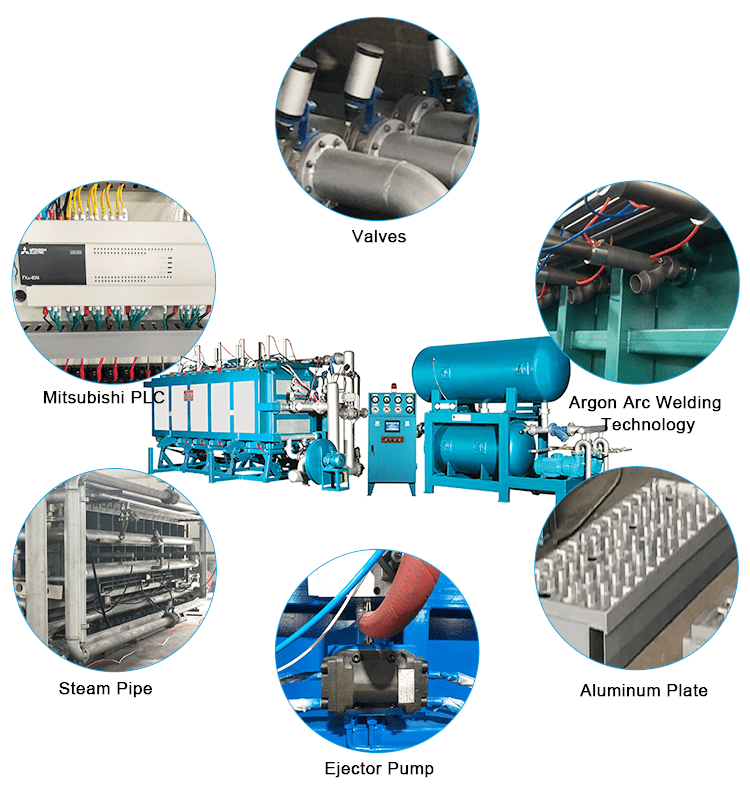

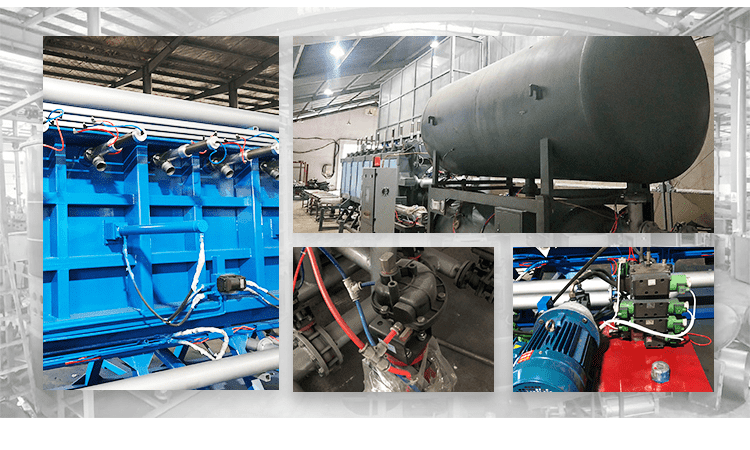

Polystyrène blòk bòdi machin ak vakyòm ranpli ak kò machin prensipal, bwat kontwòl, sistèm vakyòm, peze sistèm elatriye.

Polystyrène blòk bòdi machin ak avantaj vakyòm:

1.Machine se te fè nan segondè - tib kare fòs ak plak asye epè;

2.Machine sèvi ak 5mm epè plak vapè aliminyòm ak tflon kouch. Ak anba plak aliminyòm, pi gwo sipò gwosè nan plis kantite yo mete pou fè pou evite plak aliminyòm defòme anba presyon ki wo. Plak aliminyòm pa't chanje fòm apre dis ane k ap travay;

3.Machine'S tout sis panno yo se nan tretman chalè lage estrès soude, se konsa ke panno pa ka defòme anba tanperati ki wo;

4.Machine ak plis liy vapè asire vapeur menm nan blòk, se konsa blòk fizyon se pi bon;

5. Plak machin yo ak pi bon sistèm drenaj pou blòk yo pi seche epi yo ka koupe nan tan kout;

6.Tout plak machin nan rouye retire, boul flite, Lè sa a, fè anti - penti baz rouye ak penti sifas, se konsa kò machin se pa fasil jwenn rusted;

7.Machine Sèvi ak Smart kanalizasyon sistèm ak vapeur pwosesis, asire bon fizyon nan blòk tou de pou dansite segondè ak dansite ki ba;

8. Fast System System ak efikas sistèm vakyòm asire machin vit k ap travay, chak blòk 4 ~ 8 minit;

9.Ejection se kontwole pa ponp idwolik, se konsa tout ejectors pouse epi retounen nan menm vitès;

10.Pifò konpozan yo itilize nan machin nan yo enpòte oswa pi popilè pwodwi make.

Prensipal paramèt teknik

Sijè | Inite | PB2000V | PB3000V | PB4000V | PB6000V | |

Gwosè kavite mwazi | mm | 2040*1240*1030 | 3060*1240*1030 | 4080*1240*1030 | 6100*1240*1030 | |

Gwosè blòk | mm | 2000*1200*1000 | 3000*1200*1000 | 4000*1200*1000 | 6000*1200*1000 | |

Vapè | Antre | Pous | 2 '' (DN50) | 2 '' (DN50) | 6 '' (DN150) | 6 '' (DN150) |

Konsomasyon | Kg/sik | 25 ~ 45 | 45 ~ 65 | 60 ~ 85 | 95 ~ 120 | |

Presyon | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Lè konprese | Antre | Pous | 1.5 '' (DN40) | 1.5 '' (DN40) | 2 '' (DN50) | 2 '' (DN50) |

Konsomasyon | m³/sik | 1.5 ~ 2 | 1.5 ~ 2.5 | 1.8 ~ 2.5 | 2 ~ 3 | |

Presyon | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Vakyòm dlo refwadisman | Antre | Pous | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) |

Konsomasyon | m³/sik | 0.4 | 0.6 | 0.8 | 1 | |

Presyon | MPA | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | |

Drenaj | Drenaj vakyòm | Pous | 4 '' (DN100) | 5 '' (DN125) | 5 '' (DN125) | 6 '' (DN150) |

Desann vantilasyon vapè | Pous | 4 '' (DN100) | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | |

Air refwadisman vantilasyon | Pous | 4 '' (DN100) | 4 '' (DN100) | 6 '' (DN150) | 6 '' (DN150) | |

Kapasite 15kg/m³ | Min/sik | 4 | 5 | 7 | 8 | |

Konekte chaj/pouvwa | Kw | 19.75 | 23.75 | 24.5 | 32.25 | |

An jeneral dimansyon (L*h*w) | mm | 5700*4000*2800 | 7200*4500*3000 | 11000*4500*3000 | 12600*4500*3100 | |

Pwa | Kg | 5000 | 6500 | 10000 | 14000 | |

Ka

Videyo ki gen rapò

Our technical team is committed to supporting you in mastering the functionality of the Electric Hot Wire Foam Cutter. We provide comprehensive training and post-purchase support to assist you in harnessing the full potential of this versatile machine. Invest in the future of EPS block moulding with the Electric Hot Wire Foam Cutter from Dongshen, a machine that embodies innovation, efficiency, and performance like none other in the market. Revolutionize your EPS manufacturing process with the advanced technology of our Polystyrene Block Moulding Machine. Experience the Dongshen difference today.