Dekouvri granulatè revolisyonè Dongshen a pou pwodiksyon blòk kim EPS

Detay pwodwi yo

Expanded polystyrène kim blòk fè machin yo itilize fè blòk EPS, Lè sa a, koupe nan fèy papye pou izolasyon kay oswa anbalaj. Pwodwi popilè yo te fè soti nan fèy papye EPS yo se panno sandwich EPS, panno 3D, anndan ak deyò panno izolasyon miray, anbalaj vè, anbalaj mèb elatriye.

Expanded Polystyrène kim blòk fè machin se apwopriye pou ti demann kapasite ak ba dansite blòk pwodiksyon, li nan machin EPS ekonomik. Avèk teknoloji espesyal, nou elaji polystyrène kim blòk fè machin ka fè 4G/L blòk dansite, blòk se dwat ak nan bon jan kalite bon.

Machin konplete ak kò prensipal, bwat kontwòl, balèn, peze sistèm elatriye.

Karakteristik prensipal

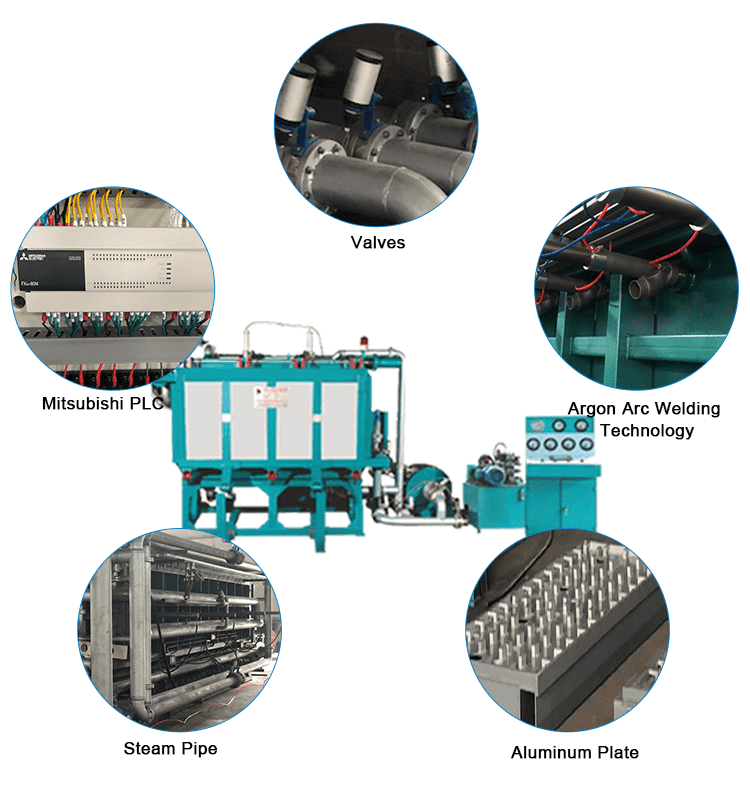

1. Machin nan adopte Mitsubishi PLC ak Winview Touch ekran pou ouvèti mwazi otomatik, fèmen mwazi, ranpli materyèl, vapeur, kenbe tanperati a, refwadisman lè, demould ak retire li.

2. Machine a tout sis panno yo se nan tretman chalè lage estrès soude, se konsa ke panno pa ka defòme anba tanperati ki wo;

Se kavite mwazi te fè nan plak espesyal alyaj aliminyòm ak segondè - kondiksyon chalè efikasite, epesè plak aliminyòm 5mm, ak kouch tflon pou demoulding fasil.

4. Machin nan mete kanpe segondè - presyon balèn pou materyèl pou aspirasyon. Se refwadisman fè pa lè konveksyon pa balèn.

5. Plak machin yo soti nan segondè - bon jan kalite pwofil, nan tretman chalè, fò ak pa gen okenn deformation.

6. Ejection kontwole pa ponp idwolik, se konsa tout èkstrakteur pouse epi retounen nan menm vitès;

Prensipal paramèt teknik

Sijè | Inite | PB2000A | PB3000A | PB4000A | PB6000A | |

Gwosè kavite mwazi | mm | 2040*1240*630 | 3060*1240*630 | 4080*1240*630 | 6100*1240*630 | |

Gwosè blòk | mm | 2000*1200*600 | 3000*1200*600 | 4000*1200*600 | 6000*1200*600 | |

Vapè | Antre | Pous | Dn80 | Dn80 | DN100 | DN150 |

| Konsomasyon | Kg/sik | 18 ~ 25 | 25 ~ 35 | 40 ~ 50 | 55 ~ 65 |

| Presyon | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 |

Lè konprese | Antre | Pous | DN40 | DN40 | DN50 | DN50 |

| Konsomasyon | m³/sik | 1 ~ 1.2 | 1.2 ~ 1.6 | 1.6 ~ 2 | 2 ~ 2.2 |

| Presyon | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 |

Drenaj | Vantilasyon vapè | Pous | DN100 | DN150 | DN150 | DN150 |

Kapasite 15kg/m³ | Min/sik | 4 | 5 | 7 | 8 | |

Konekte chaj/pouvwa | Kw | 6 | 8 | 9.5 | 9.5 | |

An jeneral dimansyon (L*h*w) | mm | 3800*2000*2100 | 5100*2300*2100 | 6100*2300*2200 | 8200*2500*3100 | |

Pwa | Kg | 3500 | 5000 | 6500 | 9000 | |

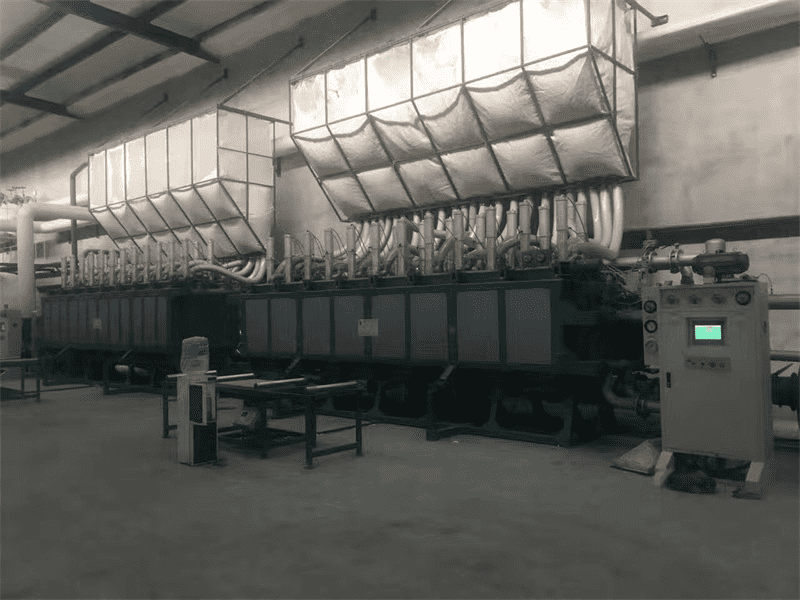

Ka

Videyo ki gen rapò

Using the Styrofoam Granulator is an incredible way to keep production costs down while enhancing output quality. Its ease of operation and maintenance further adds to the productivity of the process, making it an indispensable tool for any industry relying on EPS foam blocks. In conclusion, Dongshen's Styrofoam Granulator is not only a game-changer in the production of EPS foam blocks, but it is also a significant step towards developing more sustainable and efficient industrial processes. Relying on this machine means entrusting the production of your EPS foam blocks to a fast, reliable, and cost-effective solution, which ultimately leads to maximized productivity and profitability in your operations. Trust in Dongshen’s innovation to meet and exceed your industry's requirements.