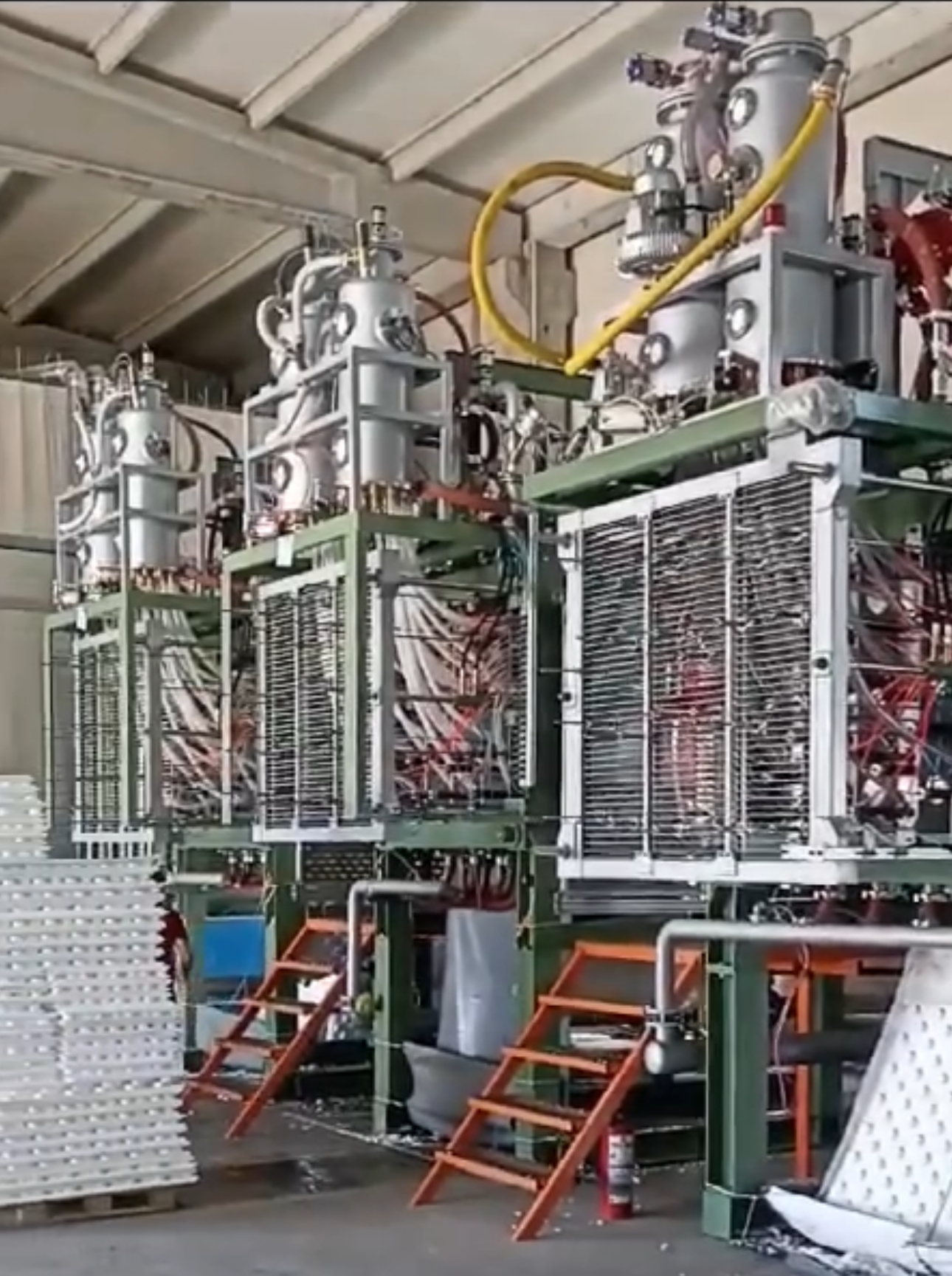

Lag Luam Wholesale Eps Txhaj Tshuaj Moulding Tshuab Rau Ntau Daim Ntawv Thov

Khoom cov tsis muaj cov khoom lag luam tseem ceeb

| Chaw ua uas tsis tau haus | Cov ntsiab lus |

|---|---|

| PWM NTIM | 2200 * 1650 hli |

| Max Cov Khoom Muaj Peev Xwm | 2050 * 1400 * 400 mm |

| Ncej Nkag | 5 '' (dn125) |

| Kev noj | 9 ~ 11 kg / kev voj voog |

| Nyem | 0.4 ~ 0.6 MPa |

| Cua Txias Dej Nkag | 4 '' (DN100) |

| Qho hnyav | 8200 kg |

Cov Khoom Lag Luam Khoom Tshwj Xeeb

| Kev qhia tshwj xeeb | Cov ntsiab lus |

|---|---|

| Txoj hlab ntsha | 150 ~ 1500 hli |

| Nce Siab | 3 ~ 4bar |

| Hwjchim | 17.2 kW |

| Zuag Tawm Ib Zos | 5100 * 2460 * 5500 hli |

Cov khoom lag luam tsim khoom

EPS txhaj tshuaj molding tshuab ua haujlwm ntawm cov kauj ruam los tsim cov khoom lag luam siab siab. Thaum pib, Raw EPS Beads tau ua ntej ua ntej ua ntej - Kev nthuav dav los ntawm kev thov cua sov. Cov kauj ruam no yog qhov tseem ceeb heev rau kev ua tiav qhov chaw siab loj thiab ntom ntom, uas yog qhov tseem ceeb rau cov khoom siv hluav taws xob ruaj khov thiab cov khoom siv rwb thaiv tsev. Tom qab ntawd, cov hlaws dai yog txias rau qhov sib npaug. Cov hlaws dai yog tom qab txhaj rau hauv cov pwm, ua raws los ntawm cov cua sov, fusing, txias, thiab Ejection-txhua kauj ruam tau tswj hwm kom ntseeg tau tias cov khoom muaj kev ncaj ncees.

Khoom Daim Ntawv Thov

EPS Txhaj Tshuaj Moulding yog ua haujlwm thoob plaws ntau txoj haujlwm vim nws lub teeb yuag, thermal rwb thaiv tsev, thiab muaj zog zoo. Nws yog ubiquitously siv nyob rau hauv kev lag luam ntim rau kev ua yeeb nkab ntim rau cov khoom muag zoo li hluav taws xob thiab cov khoom siv hluav taws xob. Hauv kev ua haujlwm, nws cov khoom siv rwb thaiv tsev yog siv zog rau lub zog - kev daws teeb meem. Ib qho ntxiv, vim nws txoj kev yoog tau, nws tseem siv rau kev tsim cov ntaub ntawv qhia kev kawm thiab cov khoom lag luam ua si.

Khoom tom qab - muag kev pabcuam

Peb muab cov kev pabcuam rau peb cov kev muag khoom rau peb cov lag luam wholesale EPS txhaj tshuaj molding tshuab, suav nrog kev txhawb nqa kev pab, kev txij nkawm, thiab hloov kev kho. Peb cov pab pawg kws tshaj lij yog muaj los daws cov teeb meem ua haujlwm thiab xyuas kom meej txog qhov siab tshaj plaws nyob rau. Cov neeg siv tau txais cov ntaub ntawv thiab cov txheej txheem daws teeb meem thiab cov txheej txheem daws teeb meem.

Cov Tsheb Thauj Mus Los

Peb lub EPS txhaj tshuaj molding rau kev xa khoom siv peb cov neeg uas ntseeg siab ntseeg tau ua kom muaj kev nyab xeeb thiab xa sijhawm. Peb muab kev xa khoom thoob ntiaj teb thiab kev sib koom tes nrog cov neeg siv nyiaj kom ua raws li cov kev tswj thiab cov ntaub ntawv hauv nroog.

Cov khoom lag luam zoo

- Ua tau zoo thiab ceev ntau lawm

- Txo Kev Siv Zog

- Customizable rau ntau yam khoom duab

- Tsawg txij nkawm nrog siab - Cov Khoom Siv Zoo

- Saj zawg zog rau ntau daim ntawv thov muaj

Khoom Muag FAQ

- Lub tshuab txhim kho tau zoo li cas?Peb lub EPS txhaj tshuaj molding tshuab txo lub sijhawm voj voog los ntawm 25% thiab kev siv zog los ntawm 25%, txhim kho cov kev ua haujlwm ntau dua.

- Yuav ua li cas cov kev saib xyuas yuav tsum tau ua?Kev tu ib txwm muaj xws li kuaj xyuas cov chav tsev hydraulic thiab chav dej, ntxuav lim dej, thiab ua kom tsim nyog lubrication los tiv thaiv kev hnav thiab kua muag.

- Lub tshuab puas tuaj yeem siv ntau yam khoom hom?Yog lawm, lub tshuab txhawb ntau cov pwm rau cov khoom sib txawv EPS, los ntawm ntim mus rau cov khoom siv.

- Puas yog kev txhawb nqa kev lag luam muaj?Yog lawm, peb pab neeg muab cov kev txhawb nqa kev ua haujlwm txuas ntxiv thiab kev pab cuam daws teeb meem thiab kev coj ua haujlwm.

- Dab tsi yog lub neej ib txwm siv lub tshuab?Nrog kev tu kom tsim nyog, lub tshuab tuaj yeem nyob ntev dua ib xyoo caum, txhawb nqa los ntawm cov phiaj hlau ruaj khov thiab cov khoom muaj zog.

- Puas muaj kev txhawj xeeb ib puag ncig?Thaum EPS tsis yog biodegradable, kev siv zog nyob rau hauv cov txheej txheem ua dua tshiab tab tom ua kom haum ib puag ncig ib puag ncig.

- Cov ntaub ntawv thauj khoom yog dab tsi?Cov tshuab tau xa mus thoob ntiaj teb nrog peb cov koom nrog logistics, kom ntseeg tau ruaj khov thiab xa khoom raws sijhawm thiab sijhawm.

- Puas muaj peev xwm pab nyiaj EPS yuav rov ua dua tshiab?Yog lawm, kev xaiv rov siv dua tshiab, thiab peb ntxias tau ib puag ncig lub luag haujlwm pov tseg ntawm EPS cov khoom lag luam.

- Puas muaj kev cob qhia rau tshuab ua haujlwm?Yog lawm, peb muab kev cob qhia cob qhia thiab cov ncauj lus kom ntxaws rau cov neeg ua haujlwm kom ntseeg tau tias muaj kev nyab xeeb thiab siv tau zoo.

- Cov qauv zoo li cas yog lub tshuab ua ke?Lub tshuab yog tsim ua adherefering rau cov qauv zoo thoob ntiaj teb, siv siab dua - qib rau kev ntseeg tau.

Khoom Kub Khoom Kub

- Kev Tsim Kho Hauv EPS Moulding TechnologyKev nce qib hauv EPS Txhaj Tshuaj Molding tshuab tau ua rau ntau dua effecomiciency thiab customization cov kev xaiv, pab txhawb kev lag luam ntau hom thoob ntiaj teb.

- Kev cuam tshuam ib puag ncig ntawm EPSThaum EPS cov khoom lag luam tsis yog biodegradable, rov ua dua tshiab thiab thev naus laus zis tau hloov kho sai heev rau kev tswj hwm cov kev ntsuas ib puag ncig.

- Cov ntaub ntawv ePS thiab cov ntaub ntawv rwb thaiv tsev ib txwm muajEPS muaj cov thermal devermal thermal thermal rwb thaiv tsev piv rau lwm txoj kev tsim kho, ua rau kev xaiv ua kev tsim kho rau lub zog - Cov Vaj Tse.

- Lub Luag Hauj Lwm Ntawm EPS Moulding Machine Hauv NtimVim nws poob siab - nqus tau lub peev xwm, EPS tseem yog cov khoom tseem ceeb hauv kev ntim khoom, tiv thaiv cov khoom noj thaum lub sijhawm tsheb thauj mus los.

- Zog ua hauj lwm zoo nyob rau EPS ntau lawmQhov tseeb EPS Txhaj Tshuaj Moulding machine ntxim nyiam txo cov zog kev noj, ua raws li lub zog thoob ntiaj teb - txuag kev pib ua haujlwm thiab txo tus nqi txo.

- Kev Lag Luam Thoob Ntiaj Teb Kev Lag Luam rau EPS KhoomQhov kev thov rau EPS cov khoom lag luam yog nyob rau sawv, nrog cov ntawv thov nce nyob rau muaj ntau yam haujlwm xws li Automotive, thiab kev tsim kho.

- Cov txheej txheem thev naus laus zis hauv EPS mouldingTsis ntev los no kev tsim kho hauv EPS moulding thev naus laus zis tau pua txoj kev rau kev sib txuas lus nrawm dua, cov khoom lag luam tau zoo dua qub.

- Kev Cuam Tshuam ntawm EPS ntawm kev tsim kho niaj hnubQhov yoog tau thiab rwb thaiv tsev thaj chaw ntawm EPS txoj hauj lwm nws ua cov khoom tseem ceeb hauv kev ruaj khov thiab lub zog - txuag lub tsev tsim.

- Cov kev sib tw hauv EPS Khib Tswj XyuasHais txog qhov muab pov tseg thiab rov qab siv dua tshiab tseem muaj kev sib tw, txawm hais tias yog ua rau muaj kev txhim kho cov hau kev zoo.

- Yav tom ntej kev cia siab ntawm Eps Moulding TechnologyNrog rau kev tshawb fawb txuas ntxiv thiab kev tsim kho tshiab, EPS moulding technology yog poised rau kev nce qib ntxiv, muaj txiaj ntsig zoo dua thiab ua tau zoo.

Duab piav qhia