EPS Tshuab - Dongshen

Hangzhou Donghen Machinery ENGINESS ENGYA ENGYA ENGYA ENGANE ENGINAINERY ENTAINERY ENTAINERY ENTAINERY ENTORSEMENTS MACON Kev Ua Kom Zoo Tshaj Plaws HauvEPS MACHINERY MACHINERYKev lag luam, koom rau lub ntiaj teb cov neeg siv nrog cov khoom lag luam siab - Cov khoom zoo thiab kev pabcuam zoo tshaj plaws. Tshwj xeeb hauv ntau lub tshuab EPS, suav nrog EPS Preexpanders,EPS Thaiv Moulding Tshuabs, thiab tshwj xeeb tshaj plawsEPS Zoo Moulding Tshuab, Donghen tau tsim lub koob npe nrov rau kev ntseeg tau thiab kev hloov tshiab.

Peb lub zog nyob hauv cov lus dag tsis yog nyob hauv peb cov machinery machinery tab sis kuj hauv peb cov kev txhawb nqa dav rau cov neeg siv khoom. Peb muab cov haujlwm tseem ceeb tshaj plaws (cov haujlwm tseem ceeb, los ntawm kev tsim cov khoom lag luam EPS tshiab los txhim kho cov uas twb muaj lawm thiab kev txuag hluav taws xob. Peb EPS moulding tshuab kab, suav nrog 2200e eps lub tshuab nqus cua ntsawj rau panels thiab EPS

Tsis tas li ntawd, Dongshen excrels hauv kev tsim cov EPS kev cai pwm thiab cov khoom lag luam spare, Kaus Lim, Nyiv, thiab Jordan. Peb kuj tseem yog Pestering cov txheej txheem cov khoom siv raw, ua kom cov txheej txheem seamless ntau lawm nrog peb lub xeev - ntawm - cov tso tsheb hlau luam, ntxuav cov cav tov, thiab sieving machine.

Kev ntseeg siab los ntawm cov neeg tau txais ib xyoo caum, Dongsen ua kom zoo los ntawm kev soj ntsuam tsis zoo thiab cov tswv yim sourcing. Peb cov neeg tau txais kev xaiv lawv raws li lawv tus khub nyob hauv Suav teb, kev sib raug zoo peb ua rau muaj nuj nqis thiab taw rau kev ua kom zoo tshaj plaws los ntawm peb cov lag luam ua lag luam.

Peb lub zog nyob hauv cov lus dag tsis yog nyob hauv peb cov machinery machinery tab sis kuj hauv peb cov kev txhawb nqa dav rau cov neeg siv khoom. Peb muab cov haujlwm tseem ceeb tshaj plaws (cov haujlwm tseem ceeb, los ntawm kev tsim cov khoom lag luam EPS tshiab los txhim kho cov uas twb muaj lawm thiab kev txuag hluav taws xob. Peb EPS moulding tshuab kab, suav nrog 2200e eps lub tshuab nqus cua ntsawj rau panels thiab EPS

Tsis tas li ntawd, Dongshen excrels hauv kev tsim cov EPS kev cai pwm thiab cov khoom lag luam spare, Kaus Lim, Nyiv, thiab Jordan. Peb kuj tseem yog Pestering cov txheej txheem cov khoom siv raw, ua kom cov txheej txheem seamless ntau lawm nrog peb lub xeev - ntawm - cov tso tsheb hlau luam, ntxuav cov cav tov, thiab sieving machine.

Kev ntseeg siab los ntawm cov neeg tau txais ib xyoo caum, Dongsen ua kom zoo los ntawm kev soj ntsuam tsis zoo thiab cov tswv yim sourcing. Peb cov neeg tau txais kev xaiv lawv raws li lawv tus khub nyob hauv Suav teb, kev sib raug zoo peb ua rau muaj nuj nqis thiab taw rau kev ua kom zoo tshaj plaws los ntawm peb cov lag luam ua lag luam.

Khoom

-

EPS nthuav dav polystyrene tshuab chaw tsim tshuaj paus

-

DS1100 - FDS1660 EPS Batch Ntaus Pre expander

-

Tsis siv neeg polystyrene hlaws dai nthuav dav tshuab

-

BATCH HOM EPS MACHINERY STYROFOAM TSHUAB

-

Qhov Zoo Tshaj Nqe EPS Polystyrene Expander Npuas Tshuab

-

EPS Pib Batch ua ntej - Expander EPS hlaws ua tshuab

-

EPS POLYSTYRENE STYROFOAM BEADS FILLING TSHUAB

-

EPS Foaming Tshuab rau nthuav polystyrene hlaws hlaws

-

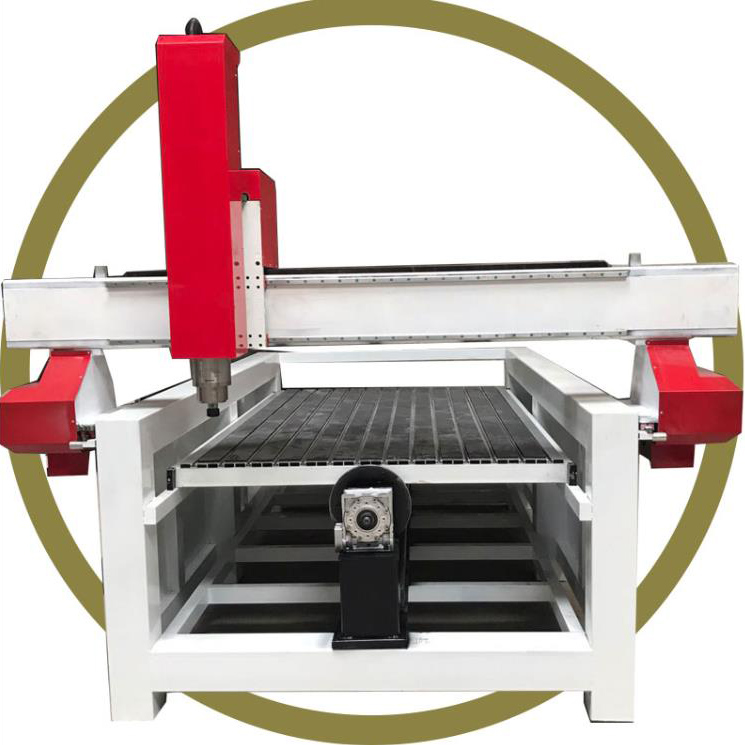

EPS Thaiv Moulding Tshuab

-

EPS FOAM CARKING TSHUAB

-

EPS Thaiv Moulding Tshuab Chaw tsim tshuaj paus

-

EPS Thaiv Moulding Tshuab Tsum

Cov Khoom FAQ

Tshuab EPS yog dab tsi?▾

EPS Machine (Xwm Txheej Ceev Polystyrene Machine) Ua kom muaj cov npe ua npuasys, uas tau paub txog lawv cov ntawv thov hauv kev ntim khoom thiab rwb thaiv tsev. Cov tshuab no tau tsim los hloov polystyrene hlaws rau hauv cov foams uas yog tom qab ntawd siv ntau yam lag luam. Nkag siab txog cov lus qhia ntawm EPS Machine yog qhov tseem ceeb rau cov lag luam koom nrog kev tsim khoom, ntim khoom thiab kev tsim kho.

● Cov tshuab EPS dab tsi yog dab tsi?

EPS Machine thiab lawv cov khoom siv

Lub tshuab EPS yog tsim los hloov cov khoom siv tau yooj ywm polystyrene polystyrene polystyrene polystyrene polystyrene polystyrene polystyrene polystyrene polystyrene polystyren los ntawm cov cua sov, nthuav dav thiab tsim cov txheej txheem. Daim ntawv qhia tag nrho ntawm cov khoom siv EPS feem ntau muaj ob peb cov kev sib xyaw ua ke, txhua tus ntawm lub luag haujlwm tshwj xeeb hauv kab. Cov khoom siv no yog:

- Ua ntej - Foaming tshuab: qhov no yog thawj theem uas cov nqaij nyoos Polystyrene hlaws liab yog nthuav tawm kom ua kom huv si thiab nthuav lawv. -

Thaiv Kev Ua Raws Cov Machine: Cov tshuab no yog qhov tseem ceeb vim tias lawv cov duab foamed hlaws rau hauv cov loj uas tuaj yeem txiav thiab tsim raws li cov kev tshwj xeeb. -

Tsis siv neeg txoj kev sib sau machine: Cov no yog cov kws tshaj lij Eps Shating qauv ua ntej - Bubbling hlaws rau hauv cov ntawv thov tshwj xeeb. -

Cutter: Tom qab tsim, cov npaus yog txiav rau cov duab uas xav tau thiab qhov loj me, npaj txhij rau daim ntawv thov zaum kawg. -

Rov qab siv Pelletizer: Cov feem tiv thaiv no ua kom muaj ntau lawm los ntawm kev rov ua cov khib nyiab polystyrene mus rau hauv cov hlaws dai tau siv.

● EPS Moulding txheej txheem

Ua Ntej - Bubbling theem

EPS tsim cov txheej txheem pib los ntawm kev ua ntej - Foaming theem. Nyob rau theem no, cov hlaws nyoos polystyrene tau muab tso rau hauv lub tshuab ua ntej - Foaming rau chav kho. Cov cua sov tsim los ntawm cov chav so kom zoo nkauj thiab nthuav cov hlaws dai, nce lawv cov ntim. Qhov kev nthuav dav thawj yog qhov tseem ceeb rau kev sib sau cov qauv ntxig ntawm cov npaus.

Cua Sov Thiab P ..

Tom qab ua ntej - foaming, cov hlaws dai yog rhuab thiab nias. Lub tshuab npau npau npau npau npau npau npau npau npau tau ntxiv rau cov hlaws dai. Nyob rau hauv tshav kub kub thiab siab, lub blowing tus neeg sawv cev rau hauv cov hlaws dai, ua rau txuas ntxiv thiab tsim cov qauv ua npuas ncauj. Qeb no yog qhov tseem ceeb heev los xyuas kom meej tias cov hlaws pleev kom ua tiav qhov yuav tsum tau ntom thiab cov qauv txheej txheem.

Txias thiab Laus

Tom qab cua sov, qhov nthuav tawm cov hlaws dai uas dhau mus ua ntu txias. Raws li lawv txias, cov pentane siv nyob rau hauv lub tshuab Lub tshuab nqus lub tshuab nqus no ua rau muaj qhov loj kawg thiab ntom ntawm cov hlaws dai. Cov hlaws dai yog tom qab ntawd cov laus los ruaj khov lawv ua ntej txav mus rau theem tom ntej.

EPS Txoj Kev Siv Lub Tshuab

Ib qho ntawm cov feem ntau tshwj xeeb hauv EPS neeg siv tshuab yog EPS txoj kev ua tshuab. Cov cav tov no tsim rau qhov siab precision, ua rau cov tuam txhab tsim khoom lag luam kom tsim kev lag luam thiab qhov ntau thiab tsawg raws kev lag luam kev lag luam tshwj xeeb. Txawm hais tias siv rau ntim cov khoom siv hluav taws xob lossis cov khoom lag luam ua kom ntseeg tau tias cov khoom lag luam zoo nkauj thiab cov khoom siv tshwj xeeb.

Txiav thiab Rov Ua Dua Tshiab

Tom qab foam thaiv yog tsim, lub cutter txiav nws ua ntau yam duab thiab ntau thiab tsawg. Cov kauj ruam no yog qhov tseem ceeb heev rau kev kho kom zoo nkauj raws li nws siv kawg, txawm siv rau hauv, kev tsim kho, lossis lwm yam kev siv. Thaum kawg, ib qho pov tseg los ntawm cov pelletizer txheej txheem siv dua tshiab, uas rov ua dua tshiab rau hauv cov hlaws nplaum ua rau cov txheej txheem kev tsim khoom lag luam.

● Cov ntawv thov thiab cov txiaj ntsig

EPS Machine pab txhawb kev tsim cov khoom ntau ntawm ntau yam ntawm cov khoom siv ua npuas dej ntau ntau. Ntawm cov ntaub ntawv ntim khoom kom tiv thaiv cov khoom tawg thaum lub caij rwb thaiv tsev kom txhim kho kev ua haujlwm, EPS ua npuas dej muaj ntau yam kev siv. Cov txiaj ntsig ntawm kev siv EPS lub tshuab muaj xws li tus nqi ua tau zoo, cov khoom siv khoom siv, thiab muaj peev xwm tsim cov duab kev cai thiab ntau los ntawm EPS txoj kev ua tshuab.

Hauv ntej, eps lub tshuab yog qhov tseem ceeb nyob rau hauv kev tsim cov khoom siv ua npuas dej polystyrene ua npuas ncauj thiab ua si lub luag haujlwm tseem ceeb hauv kev lag luam ntau yam. Nkag siab txog lawv kev ua haujlwm, Cheebtsam, thiab tag nrho cov txheej txheem molding qhia kev pom rau kev ua haujlwm tau zoo thiab muaj peev xwm ntawm EPS tsim khoom. Nrog rau cov khoom siv xws li EPS cov qauv, cov kab ntawv no muab cov kev daws teeb meem ntau ntxiv thiab ntau yam ua npuas dej.

● Cov tshuab EPS dab tsi yog dab tsi?

EPS Machine thiab lawv cov khoom siv

Lub tshuab EPS yog tsim los hloov cov khoom siv tau yooj ywm polystyrene polystyrene polystyrene polystyrene polystyrene polystyrene polystyrene polystyrene polystyrene polystyren los ntawm cov cua sov, nthuav dav thiab tsim cov txheej txheem. Daim ntawv qhia tag nrho ntawm cov khoom siv EPS feem ntau muaj ob peb cov kev sib xyaw ua ke, txhua tus ntawm lub luag haujlwm tshwj xeeb hauv kab. Cov khoom siv no yog:

- Ua ntej - Foaming tshuab: qhov no yog thawj theem uas cov nqaij nyoos Polystyrene hlaws liab yog nthuav tawm kom ua kom huv si thiab nthuav lawv. -

Thaiv Kev Ua Raws Cov Machine: Cov tshuab no yog qhov tseem ceeb vim tias lawv cov duab foamed hlaws rau hauv cov loj uas tuaj yeem txiav thiab tsim raws li cov kev tshwj xeeb. -

Tsis siv neeg txoj kev sib sau machine: Cov no yog cov kws tshaj lij Eps Shating qauv ua ntej - Bubbling hlaws rau hauv cov ntawv thov tshwj xeeb. -

Cutter: Tom qab tsim, cov npaus yog txiav rau cov duab uas xav tau thiab qhov loj me, npaj txhij rau daim ntawv thov zaum kawg. -

Rov qab siv Pelletizer: Cov feem tiv thaiv no ua kom muaj ntau lawm los ntawm kev rov ua cov khib nyiab polystyrene mus rau hauv cov hlaws dai tau siv.

● EPS Moulding txheej txheem

Ua Ntej - Bubbling theem

EPS tsim cov txheej txheem pib los ntawm kev ua ntej - Foaming theem. Nyob rau theem no, cov hlaws nyoos polystyrene tau muab tso rau hauv lub tshuab ua ntej - Foaming rau chav kho. Cov cua sov tsim los ntawm cov chav so kom zoo nkauj thiab nthuav cov hlaws dai, nce lawv cov ntim. Qhov kev nthuav dav thawj yog qhov tseem ceeb rau kev sib sau cov qauv ntxig ntawm cov npaus.

Cua Sov Thiab P ..

Tom qab ua ntej - foaming, cov hlaws dai yog rhuab thiab nias. Lub tshuab npau npau npau npau npau npau npau npau npau tau ntxiv rau cov hlaws dai. Nyob rau hauv tshav kub kub thiab siab, lub blowing tus neeg sawv cev rau hauv cov hlaws dai, ua rau txuas ntxiv thiab tsim cov qauv ua npuas ncauj. Qeb no yog qhov tseem ceeb heev los xyuas kom meej tias cov hlaws pleev kom ua tiav qhov yuav tsum tau ntom thiab cov qauv txheej txheem.

Txias thiab Laus

Tom qab cua sov, qhov nthuav tawm cov hlaws dai uas dhau mus ua ntu txias. Raws li lawv txias, cov pentane siv nyob rau hauv lub tshuab Lub tshuab nqus lub tshuab nqus no ua rau muaj qhov loj kawg thiab ntom ntawm cov hlaws dai. Cov hlaws dai yog tom qab ntawd cov laus los ruaj khov lawv ua ntej txav mus rau theem tom ntej.

EPS Txoj Kev Siv Lub Tshuab

Ib qho ntawm cov feem ntau tshwj xeeb hauv EPS neeg siv tshuab yog EPS txoj kev ua tshuab. Cov cav tov no tsim rau qhov siab precision, ua rau cov tuam txhab tsim khoom lag luam kom tsim kev lag luam thiab qhov ntau thiab tsawg raws kev lag luam kev lag luam tshwj xeeb. Txawm hais tias siv rau ntim cov khoom siv hluav taws xob lossis cov khoom lag luam ua kom ntseeg tau tias cov khoom lag luam zoo nkauj thiab cov khoom siv tshwj xeeb.

Txiav thiab Rov Ua Dua Tshiab

Tom qab foam thaiv yog tsim, lub cutter txiav nws ua ntau yam duab thiab ntau thiab tsawg. Cov kauj ruam no yog qhov tseem ceeb heev rau kev kho kom zoo nkauj raws li nws siv kawg, txawm siv rau hauv, kev tsim kho, lossis lwm yam kev siv. Thaum kawg, ib qho pov tseg los ntawm cov pelletizer txheej txheem siv dua tshiab, uas rov ua dua tshiab rau hauv cov hlaws nplaum ua rau cov txheej txheem kev tsim khoom lag luam.

● Cov ntawv thov thiab cov txiaj ntsig

EPS Machine pab txhawb kev tsim cov khoom ntau ntawm ntau yam ntawm cov khoom siv ua npuas dej ntau ntau. Ntawm cov ntaub ntawv ntim khoom kom tiv thaiv cov khoom tawg thaum lub caij rwb thaiv tsev kom txhim kho kev ua haujlwm, EPS ua npuas dej muaj ntau yam kev siv. Cov txiaj ntsig ntawm kev siv EPS lub tshuab muaj xws li tus nqi ua tau zoo, cov khoom siv khoom siv, thiab muaj peev xwm tsim cov duab kev cai thiab ntau los ntawm EPS txoj kev ua tshuab.

Hauv ntej, eps lub tshuab yog qhov tseem ceeb nyob rau hauv kev tsim cov khoom siv ua npuas dej polystyrene ua npuas ncauj thiab ua si lub luag haujlwm tseem ceeb hauv kev lag luam ntau yam. Nkag siab txog lawv kev ua haujlwm, Cheebtsam, thiab tag nrho cov txheej txheem molding qhia kev pom rau kev ua haujlwm tau zoo thiab muaj peev xwm ntawm EPS tsim khoom. Nrog rau cov khoom siv xws li EPS cov qauv, cov kab ntawv no muab cov kev daws teeb meem ntau ntxiv thiab ntau yam ua npuas dej.

EPS Me Nyuam Ua Dab Tsi?▾

Txhab polystyrene (EPS) cov ntawv thov neeg kho tshuab encompass ntau yam kev lag luam, muab cov kev daws tseem ceeb los ntawm nws cov khoom siv thiab ntau yam. Raws li tus kws tshaj lij, Kuv yuav delve rau hauv lub qhov txawv ntawm eps thiab nws qhov tseem ceeb hauv kev ua haujlwm tshwj xeeb hauv eps moulding tshuab ua cov khoom siv ua ntoo.

Txhab polystyrene (EPS) Cov hlaws dai yog impregnated nrog kev ua npuas ncauj thiab muaj cov roj txuas ntxiv, ua rau muaj kev sib tw thiab muaj zog heev ua npuas ncauj. Lub kaw - cov qauv xov tooj, muaj huab cua muaj 98%, ua rau nws cov cua sov ua haujlwm, ua kom zoo nkauj eps ib qho zoo heev insulator. Qhov no muaj kev sib xyaw no tseem qiv cov nqi qis dua thiab lub zog loj dua - cov khoom siv dag zog ua piv rau cov versuality, txhim kho nws cov versatility hauv ntau cov ntawv thov.

EPS twv ntau ntau yam zoo, suav nrog kev tiv thaiv kom tsis txhob khoov thiab compression, ua rau muaj kev ruaj khov hauv load - cov kabmob. Nws txoj kev qojweight tsis muaj lub zog, ua rau nws cov khoom siv zoo rau cov ntawv thov thiab qhov hnyav. Ib qho ntxiv, nws qhov kev xaiv tshav kub tsis zoo ua rau nws xaiv tau qhov kev xaiv hauv rwb thaiv tsev, koom nrog kev ua kom muaj zog hauv cov tsev thiab qhov kub thiab txias.

Hauv kev tsim kho thiab kev ua haujlwm architectural, ePS yog dav rau nws cov khoom insulating thiab cov qauv kev ntseeg. Nws ua haujlwm ua cov khoom siv tseem ceeb hauv cov xuab zeb, muab cov thermal rwb thaiv tsev thiab kev ruaj khov. EPS thaiv thiab cov ntawv txheeb kuj tau siv nyob rau hauv kev kev siv hauv kev los tiv thaiv cov huab cua txias, ua kom muaj kev ntseeg tau ntev thiab kev ntseeg tau ntawm txoj kev tsheb. Nws txoj kev yoog raws tus kws kos duab tsim qauv rau cov duab zoo nkauj thiab cov qauv tsim, txhim kho ob qho tib si lub aesthetic thiab kev ua haujlwm ntawm cov tsev.

Eps ua si lub luag haujlwm tseem ceeb hauv kev lag luam hauv tsheb, feem ntau hauv kev tsim khoom ntawm cov tsheb uas xav tau lub teeb tseem ceeb tseem muaj cov ntaub ntawv muaj zog. Nws siv nyob rau hauv kev tsim lub rooj zaum hauv tsheb, cov neeg nyob sab hauv, thiab qee qhov kev txo lub cev, uas nyob rau hauv lem txhim kho kev ua pa roj. Lub poob siab - nqus cov khoom ntawm eps kuj tseem ceeb rau nws cov khoom siv tseem ceeb hauv kev siv kev nyab xeeb, xws li hauv bumers thiab cushioning rau kev tiv thaiv kev cuam tshuam.

EPS Moulding Machine Yog PIVOTAL nyob rau hauv kev tsim cov EPS cov khoom lag luam, ua kom cov qauv zoo thiab muaj txiaj ntsig zoo ntawm polystyrene hlaws rau cov ntawv uas xav tau. Cov cav tov ua haujlwm los ntawm kev thov kom kub thiab siab kom nthuav cov hlaws thiab pwm rau lawv cov duab, ua kom tau raws li cov kev xav tau ntawm ntau yam kev siv. Cov txheej txheem cuam tshuam ntau theem, suav nrog ua ntej - kev laus, molding, thiab txiav, txhua meticly tswj kom ntseeg tau qhov zoo thiab xwm yeem ntawm cov khoom kawg.

Kev nce qib hauv EPS Moulding thev naus laus zis tau txhim kho cov txiaj ntsig zoo thiab muaj peev xwm ntawm cov cav tov. Niaj hnub no EPS molding tshuab yog nruab nrog cov kev tswj kom nruj uas siv tau rau qhov kub thiab txias, kom pom kev nthuav dav thiab moulding. Cov kev txhawb nqa no tseem tau coj mus rau kev noj hluav taws xob thiab lub sijhawm luv thum, txhim kho cov khoom lag luam tag nrho thiab kev ruaj ntseg ntawm EPS tsim khoom.

EPS Moulding Machine yog siv hla cov khoom lag luam sib txawv los tsim cov khoom sib txawv ntawm cov khoom lag luam. Hauv kev tsim kho, lawv tsim cov vaj huam sib luag insulating, block, thiab cov duab ua kom haum rau cov kev xav tau hauv lub tsev. Nyob rau hauv lub tsheb saib tsheb, cov cav no los tsim cov khoom sib xyaw uas ua rau muaj kev nyab xeeb hauv tsheb thiab kev ua tau zoo. Tsis tas li ntawd, kev lag luam ntim kev lag luam ntawm EPS moulding tshuab los tsim cov khoom ntim cov khoom tiv thaiv uas cov khoom tiv thaiv cov khoom lag luam thaum khaws khoom thauj thaum mus cia khoom thauj khoom thaum chaw tsheb thauj mus los thiab chaw khaws khoom.

Hauv kev xaus, nthuav dav polystyrene (EPS) yog ib qho khoom siv tsis tau muaj txiaj ntsig hauv cov nqe lus, kev sib cais ntawm lub zog, rwb thaiv tsev, thiab qhov hnyav. Lub luag haujlwm ntawm EPS moulding tshuab yog qhov tseem ceeb heev thiab kho cov khoom lag luam zoo ntawm EPS cov khoom lag luam, tsav tsheb tshiab hla ntau yam kev lag luam. Raws li thev naus laus zis txuas ntxiv hloov zuj zus, cov ntawv thov thiab cov txiaj ntsig ntawm EPS yog qhov chaw ua haujlwm tseem ceeb hauv kev ua lag luam niaj hnub thiab kev tsim khoom.

Nkag siab nthuav dav polystyrene (EPS)

● Cov yam ntxwv thiab muaj pes tsawg leeg ntawm EPS

Txhab polystyrene (EPS) Cov hlaws dai yog impregnated nrog kev ua npuas ncauj thiab muaj cov roj txuas ntxiv, ua rau muaj kev sib tw thiab muaj zog heev ua npuas ncauj. Lub kaw - cov qauv xov tooj, muaj huab cua muaj 98%, ua rau nws cov cua sov ua haujlwm, ua kom zoo nkauj eps ib qho zoo heev insulator. Qhov no muaj kev sib xyaw no tseem qiv cov nqi qis dua thiab lub zog loj dua - cov khoom siv dag zog ua piv rau cov versuality, txhim kho nws cov versatility hauv ntau cov ntawv thov.

Zoo ntawm EPS hauv kev siv tshuab tshuab

EPS twv ntau ntau yam zoo, suav nrog kev tiv thaiv kom tsis txhob khoov thiab compression, ua rau muaj kev ruaj khov hauv load - cov kabmob. Nws txoj kev qojweight tsis muaj lub zog, ua rau nws cov khoom siv zoo rau cov ntawv thov thiab qhov hnyav. Ib qho ntxiv, nws qhov kev xaiv tshav kub tsis zoo ua rau nws xaiv tau qhov kev xaiv hauv rwb thaiv tsev, koom nrog kev ua kom muaj zog hauv cov tsev thiab qhov kub thiab txias.

Cov ntawv thov ntawm EPS hauv kev lag luam

● Kev tsim kho thiab kos

Hauv kev tsim kho thiab kev ua haujlwm architectural, ePS yog dav rau nws cov khoom insulating thiab cov qauv kev ntseeg. Nws ua haujlwm ua cov khoom siv tseem ceeb hauv cov xuab zeb, muab cov thermal rwb thaiv tsev thiab kev ruaj khov. EPS thaiv thiab cov ntawv txheeb kuj tau siv nyob rau hauv kev kev siv hauv kev los tiv thaiv cov huab cua txias, ua kom muaj kev ntseeg tau ntev thiab kev ntseeg tau ntawm txoj kev tsheb. Nws txoj kev yoog raws tus kws kos duab tsim qauv rau cov duab zoo nkauj thiab cov qauv tsim, txhim kho ob qho tib si lub aesthetic thiab kev ua haujlwm ntawm cov tsev.

● Kev lag luam Automotive

Eps ua si lub luag haujlwm tseem ceeb hauv kev lag luam hauv tsheb, feem ntau hauv kev tsim khoom ntawm cov tsheb uas xav tau lub teeb tseem ceeb tseem muaj cov ntaub ntawv muaj zog. Nws siv nyob rau hauv kev tsim lub rooj zaum hauv tsheb, cov neeg nyob sab hauv, thiab qee qhov kev txo lub cev, uas nyob rau hauv lem txhim kho kev ua pa roj. Lub poob siab - nqus cov khoom ntawm eps kuj tseem ceeb rau nws cov khoom siv tseem ceeb hauv kev siv kev nyab xeeb, xws li hauv bumers thiab cushioning rau kev tiv thaiv kev cuam tshuam.

Lub Luag Hauj Lwm Ntawm EPS Moulding Machine

EPS Moulding Machine Yog PIVOTAL nyob rau hauv kev tsim cov EPS cov khoom lag luam, ua kom cov qauv zoo thiab muaj txiaj ntsig zoo ntawm polystyrene hlaws rau cov ntawv uas xav tau. Cov cav tov ua haujlwm los ntawm kev thov kom kub thiab siab kom nthuav cov hlaws thiab pwm rau lawv cov duab, ua kom tau raws li cov kev xav tau ntawm ntau yam kev siv. Cov txheej txheem cuam tshuam ntau theem, suav nrog ua ntej - kev laus, molding, thiab txiav, txhua meticly tswj kom ntseeg tau qhov zoo thiab xwm yeem ntawm cov khoom kawg.

● Kev txhim kho Technological hauv EPS Moulding

Kev nce qib hauv EPS Moulding thev naus laus zis tau txhim kho cov txiaj ntsig zoo thiab muaj peev xwm ntawm cov cav tov. Niaj hnub no EPS molding tshuab yog nruab nrog cov kev tswj kom nruj uas siv tau rau qhov kub thiab txias, kom pom kev nthuav dav thiab moulding. Cov kev txhawb nqa no tseem tau coj mus rau kev noj hluav taws xob thiab lub sijhawm luv thum, txhim kho cov khoom lag luam tag nrho thiab kev ruaj ntseg ntawm EPS tsim khoom.

● Cov ntawv thov ntawm EPS Moulding Machine

EPS Moulding Machine yog siv hla cov khoom lag luam sib txawv los tsim cov khoom sib txawv ntawm cov khoom lag luam. Hauv kev tsim kho, lawv tsim cov vaj huam sib luag insulating, block, thiab cov duab ua kom haum rau cov kev xav tau hauv lub tsev. Nyob rau hauv lub tsheb saib tsheb, cov cav no los tsim cov khoom sib xyaw uas ua rau muaj kev nyab xeeb hauv tsheb thiab kev ua tau zoo. Tsis tas li ntawd, kev lag luam ntim kev lag luam ntawm EPS moulding tshuab los tsim cov khoom ntim cov khoom tiv thaiv uas cov khoom tiv thaiv cov khoom lag luam thaum khaws khoom thauj thaum mus cia khoom thauj khoom thaum chaw tsheb thauj mus los thiab chaw khaws khoom.

Hauv kev xaus, nthuav dav polystyrene (EPS) yog ib qho khoom siv tsis tau muaj txiaj ntsig hauv cov nqe lus, kev sib cais ntawm lub zog, rwb thaiv tsev, thiab qhov hnyav. Lub luag haujlwm ntawm EPS moulding tshuab yog qhov tseem ceeb heev thiab kho cov khoom lag luam zoo ntawm EPS cov khoom lag luam, tsav tsheb tshiab hla ntau yam kev lag luam. Raws li thev naus laus zis txuas ntxiv hloov zuj zus, cov ntawv thov thiab cov txiaj ntsig ntawm EPS yog qhov chaw ua haujlwm tseem ceeb hauv kev ua lag luam niaj hnub thiab kev tsim khoom.

Yog eps tib yam li styrofoam?▾

Nthuav cov polystyrene (eps) thiab styrofoam yog cov ntsiab lus feem ntau siv sib pauv sib pauv, ua rau muaj kev ntxhov siab ntawm cov neeg siv khoom thiab cov tub txawg tib yam nkaus. Txawm li cas los xij, nws yog qhov tseem ceeb kom nkag siab qhov sib txawv ntawm ob cov ntaub ntawv los siv lawv kom zoo thiab muaj kev tsim nyog hauv ntau yam kev siv.

Nthuav cov polystyrene, uas tau raug hu ua EPS, yog lub teeb yuag, nruj, thiab ntau yam ua npuas ncauj. Nws yog tsim los ntawm nthuav polystyrene hlaws dai nrog chav thiab siab, uas tau sib khi ua ke los ua cov qauv ruaj khov. EPS muaj li ntawm 98% huab cua, ua rau nws lub nra tsis txaus ntshai thiab muaj insulator zoo heev. Tsis tas li ntawd, EPS tau ruaj khov, tiv taus ya raws, thiab rov ua dua, ntxiv rau nws cov npe ntawm cov khoom muaj txiaj ntsig zoo.

Styrofoam, ntawm qhov tod tes, yog lub cim lag luam rau ib hom kev kaw lus tshwj xeeb kaw - Cell Extruded Polystyrene ua npuas ncauj. Daim ntawv tshwj xeeb ntawm polystyrene ua npuas ncauj yog engineed rau thermal rwb thaiv tsev thiab cov ntawv thov khoom siv tes ua. Thaum styrofoam sib faib qee yam ntxwv nrog EPS, xws li ua lub teeb thiab ib qho insulator thiab insulator, nws tsis yog tib yam khoom. Lo lus "styrofoam" feem ntau ua ib qho khoom lag luam hauv cov khoom siv ua npuas dej vim tias nws tau lees paub, nws hais txog ib hom ntawm polystyrene ua npuas ncauj.

Thawj qhov sib txawv ntawm EPS thiab Styrofoam nyob hauv lawv cov txheej txheem tsim qauv thiab ua rau muaj cwj pwm qauv. EPS yog tsim los ntawm nthuav polystyrene hlaws, uas tsim cov khoom sib zog ntau dua thiab cov khoom siv tsis tshua muaj. Hauv kev sib piv, Styrofoam yog tsim los ntawm kev ua tiav kev nkag mus, ua rau hauv smoother, denser, thiab ntau cov qauv ua npuas ncauj zoo sib xws.

EPS siv nyob rau hauv ib qho loj heev ntawm cov ntawv thov vim nws lub cev lub cev. Nws yog feem ntau siv nyob rau hauv ntim rau nws qhov zoo heev kev poob siab - nqus muaj peev xwm, ua kom muaj kev nyab xeeb thauj ntawm cov khoom lag luam tawg. Ib qho ntxiv, EPS Nrov nyob rau hauv kev tsim kho rau phab ntsa, hauv pem teb, ua tsaug rau nws cov thermal bermal ua condivity thiab tsis kam rau ya raws. Cov khoom siv versatility txuas ntxiv rau cov khoom noj khoom noj pov tseg, qhov twg nws muab rwb thaiv tsev zoo rau cov dej kub thiab txias.

Styrofoam thawj daim ntawv thov yog nyob rau hauv thermal rwb thaiv tsev thiab khoom siv tes ua. Nws cov neeg kaw - cov qauv xov tooj ua nws cov tshuaj insulator tshwj xeeb, siv nyob rau hauv lub tsev ringulation. Ib qho ntxiv, vim nws cov npoo du thiab yooj yim ntawm kev txiav, styrofoam yog qhov kev nyiam rau cov paj ntaub thiab ua qauv.

Ib qho ntawm qhov tseem ceeb ntawm kev tsim cov khoom siab - Cov khoom lag luam zoo EPS yog kev siv cov EPS nce qib moulding. Cov cav tov no tsim los txhawm rau kho EPS hlaws dai rau hauv ntau hom ntawv thiab ntau thiab tsawg, catering kom muaj kev lag luam tshwj xeeb. Qhov precision thiab ua tau zoo ntawm EPS niaj hnub moulding khoom siv sib xws hauv cov khoom ntom thiab cov qauv kev ncaj ncees, qhov tseem ceeb rau kev tswj cov khoom siv uas xav tau.

Los ntawm kev siv EPS moulding machine, cov chaw tsim khoom tuaj yeem tsim tau ntau cov khoom lag luam, los ntawm cov ntaub ntawv ntim ntim ruaj khov rau cov tsiaj ntawv sib xyaw. Cov tshuab 'lub peev xwm txuas ntxiv mus rau kev txheeb xyuas cov duab thiab ntau thiab tsawg, muab cov kev daws teeb meem nrog cov kev daws teeb meem uas ua tau raws li lawv cov lus qhia tseeb.

Thaum EPS thiab Styrofoam feem ntau tsis meej pem, nkag siab txog lawv cov kev siv sib txawv thiab cov ntaub ntawv tshwj xeeb yog qhov tseem ceeb rau kev txiav txim siab hauv lawv siv. EPS, muaj ntau yam khoom siv thiab cov khoom siv rov ua dua, sawv tawm rau nws siv hauv cov khoom siv hluav taws xob tshwj xeeb rau cov cua sov thiab cov laj thawj ua. Siv cov tshuab siab ua kom tiav EPS moulding machine txuas ntxiv txhim kho cov khoom lag luam zoo thiab ua tau zoo, ua kom muaj kev hloov pauv hloov tshiab hauv EPS kev lag luam thoob plaws ntau yam lag luam. Paub txog cov kev xaiv no ua kom tau cov khoom siv zoo dua thiab siv tau cov txiaj ntsig ntawm ob qho tib si thiab cov khoom lag luam.

Nkag siab EPS thiab Styrofoam

● Dab tsi yog nthuav dav polystyrene (EPS)?

Nthuav cov polystyrene, uas tau raug hu ua EPS, yog lub teeb yuag, nruj, thiab ntau yam ua npuas ncauj. Nws yog tsim los ntawm nthuav polystyrene hlaws dai nrog chav thiab siab, uas tau sib khi ua ke los ua cov qauv ruaj khov. EPS muaj li ntawm 98% huab cua, ua rau nws lub nra tsis txaus ntshai thiab muaj insulator zoo heev. Tsis tas li ntawd, EPS tau ruaj khov, tiv taus ya raws, thiab rov ua dua, ntxiv rau nws cov npe ntawm cov khoom muaj txiaj ntsig zoo.

● Dab tsi yog styrofoam?

Styrofoam, ntawm qhov tod tes, yog lub cim lag luam rau ib hom kev kaw lus tshwj xeeb kaw - Cell Extruded Polystyrene ua npuas ncauj. Daim ntawv tshwj xeeb ntawm polystyrene ua npuas ncauj yog engineed rau thermal rwb thaiv tsev thiab cov ntawv thov khoom siv tes ua. Thaum styrofoam sib faib qee yam ntxwv nrog EPS, xws li ua lub teeb thiab ib qho insulator thiab insulator, nws tsis yog tib yam khoom. Lo lus "styrofoam" feem ntau ua ib qho khoom lag luam hauv cov khoom siv ua npuas dej vim tias nws tau lees paub, nws hais txog ib hom ntawm polystyrene ua npuas ncauj.

Qhov sib txawv thiab cov siv sib txawv

● Cov ntsiab lus sib txawv

Thawj qhov sib txawv ntawm EPS thiab Styrofoam nyob hauv lawv cov txheej txheem tsim qauv thiab ua rau muaj cwj pwm qauv. EPS yog tsim los ntawm nthuav polystyrene hlaws, uas tsim cov khoom sib zog ntau dua thiab cov khoom siv tsis tshua muaj. Hauv kev sib piv, Styrofoam yog tsim los ntawm kev ua tiav kev nkag mus, ua rau hauv smoother, denser, thiab ntau cov qauv ua npuas ncauj zoo sib xws.

● Cov ntawv thov thiab cov txiaj ntsig

EPS siv nyob rau hauv ib qho loj heev ntawm cov ntawv thov vim nws lub cev lub cev. Nws yog feem ntau siv nyob rau hauv ntim rau nws qhov zoo heev kev poob siab - nqus muaj peev xwm, ua kom muaj kev nyab xeeb thauj ntawm cov khoom lag luam tawg. Ib qho ntxiv, EPS Nrov nyob rau hauv kev tsim kho rau phab ntsa, hauv pem teb, ua tsaug rau nws cov thermal bermal ua condivity thiab tsis kam rau ya raws. Cov khoom siv versatility txuas ntxiv rau cov khoom noj khoom noj pov tseg, qhov twg nws muab rwb thaiv tsev zoo rau cov dej kub thiab txias.

Styrofoam thawj daim ntawv thov yog nyob rau hauv thermal rwb thaiv tsev thiab khoom siv tes ua. Nws cov neeg kaw - cov qauv xov tooj ua nws cov tshuaj insulator tshwj xeeb, siv nyob rau hauv lub tsev ringulation. Ib qho ntxiv, vim nws cov npoo du thiab yooj yim ntawm kev txiav, styrofoam yog qhov kev nyiam rau cov paj ntaub thiab ua qauv.

EPS Moulding Machine

Ib qho ntawm qhov tseem ceeb ntawm kev tsim cov khoom siab - Cov khoom lag luam zoo EPS yog kev siv cov EPS nce qib moulding. Cov cav tov no tsim los txhawm rau kho EPS hlaws dai rau hauv ntau hom ntawv thiab ntau thiab tsawg, catering kom muaj kev lag luam tshwj xeeb. Qhov precision thiab ua tau zoo ntawm EPS niaj hnub moulding khoom siv sib xws hauv cov khoom ntom thiab cov qauv kev ncaj ncees, qhov tseem ceeb rau kev tswj cov khoom siv uas xav tau.

Los ntawm kev siv EPS moulding machine, cov chaw tsim khoom tuaj yeem tsim tau ntau cov khoom lag luam, los ntawm cov ntaub ntawv ntim ntim ruaj khov rau cov tsiaj ntawv sib xyaw. Cov tshuab 'lub peev xwm txuas ntxiv mus rau kev txheeb xyuas cov duab thiab ntau thiab tsawg, muab cov kev daws teeb meem nrog cov kev daws teeb meem uas ua tau raws li lawv cov lus qhia tseeb.

Tag

Thaum EPS thiab Styrofoam feem ntau tsis meej pem, nkag siab txog lawv cov kev siv sib txawv thiab cov ntaub ntawv tshwj xeeb yog qhov tseem ceeb rau kev txiav txim siab hauv lawv siv. EPS, muaj ntau yam khoom siv thiab cov khoom siv rov ua dua, sawv tawm rau nws siv hauv cov khoom siv hluav taws xob tshwj xeeb rau cov cua sov thiab cov laj thawj ua. Siv cov tshuab siab ua kom tiav EPS moulding machine txuas ntxiv txhim kho cov khoom lag luam zoo thiab ua tau zoo, ua kom muaj kev hloov pauv hloov tshiab hauv EPS kev lag luam thoob plaws ntau yam lag luam. Paub txog cov kev xaiv no ua kom tau cov khoom siv zoo dua thiab siv tau cov txiaj ntsig ntawm ob qho tib si thiab cov khoom lag luam.