1. Shrinkage deformation yuav tshwm sim tom qab EPS moulding thiab demoulding

Nyob rau hauv dav dav, shrinkage ntawm eps yog 0% - 0.3%. Tus nqi tshwj xeeb pov tseg yog cuam tshuam nrog cov yam ntxwv ntawm txhua cov khoom, cov txheej txheem txheej txheem (tshwj xeeb tshaj yog kub), cov khoom siv ceev thiab tuab. Hauv qee kis, xws li siab didoulding kub thiab tuab khoom, cov khoom lag luam tsis tsuas yog tsis txhob thim, tab sis nthuav dav. Yog li ntawd, shrinkage deformation ntawm EPS thiab General Cov Txheej Txheem Moulding txheej txheem yuav tsum tau txiav txim siab nyob rau hauv pwm kev tsim khoom. Qhov loj me ntawm cov pwm yuav tsum yog qhov tsim nyog loj, feem ntau 0.2%

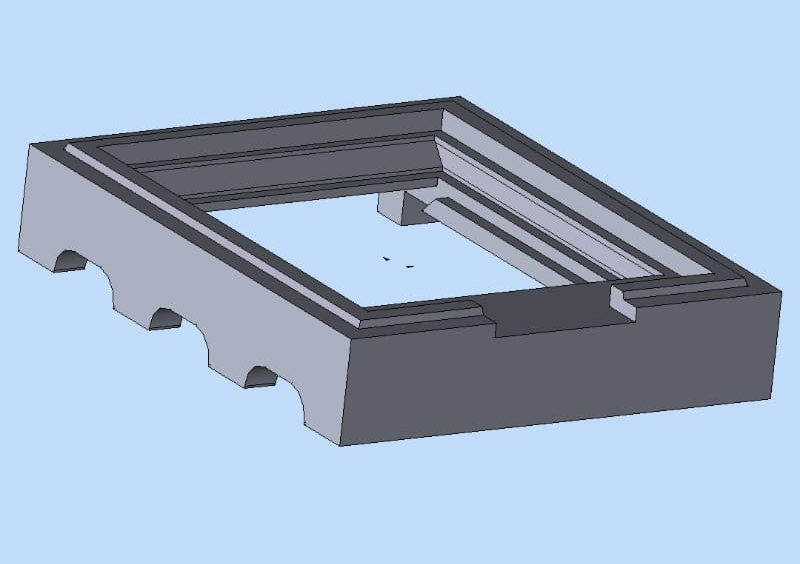

Ib qho ntxiv, nws yuav tsum tau taw qhia tias rau cov khoom ntim cov khoom siv tsis sib xws, cov tuab tuab tsis yooj yim rau txias, ua rau muaj kev nthuav dav hauv zos. Yog li ntawd, thaum tsim qauv ntim, phab ntsa tuab yuav tsum muaj kev sib dhos li sai tau, thiab cov blocks khawb yuav tsum tau ntxiv ntawm qhov chaw tuab

2. Shrinkage deformation ntawm txhuas pwm thaum lub sij hawm ua pov

Tswj cov shrinkage deformation muaj feem ntau ntawm cov teeb meem txuj ci, uas yog hais txog cov npoo ntoo formwork.

(1) Cov duab geometric thiab cov tuab ntawm cov pwm pwm yuav cuam tshuam rau shrinkage ntawm castings. Feem ntau hais lus, shrinkage deformation ntawm ntau cov nyom txhuas castings yog qhov tsawg

(2) Qhov tseeb tiag tiag ntawm cov kab hlau ua txhuas feem ntau yog 1.1 - 1.2%

(3) Cov khoom pov tseg cov ntoo muaj feem cuam tshuam nrog nws cov txheej txheem thiab cov txuj ci, tshwj xeeb tshaj yog cov txheej txheem kev cas ntawm cov txheej txheem casting. Feem ntau hais lus, qhov loj ntawm cov pwm ntoo yuav tsum muaj ntau los ntawm 1.3 - 1.8%. Txoj kev tshwj xeeb tuaj yeem txiav txim siab raws li qhov xwm txheej tiag tiag. Yog tias qhov chaw ua kom du, theem txheej txheem yog qhov siab thiab cov khoom siv shrinkage ntawm cov tog ntoo yuav tsum tseem me dua

(4) Phab ntsa ntawm cov pwm yuav tsum yog thinner thiab lub npoo yuav tsum tau smoother kom ntau li ntau tau. Yog li ntawd, cov tub ntxhais casting yuav tsum tau txhim kho qhov tseeb thiab ua tiav ntawm cov ntoo pwm

Peb cov tshuab tshuab muaj kev paub zoo thiab muaj kev paub nplua nuj ua rau muaj pwm thiab khoom siv zoo, peb tus EPS pwm tuaj yeem ua haujlwm nrawm dua thiab kav ntev dua.

Yog tias koj muaj kev nug txog EPS pwm, Txais tos kom Hu rau peb rau cov ntaub ntawv ntxiv, Ua tsaug!

Lub Sijhawm Post: Dec - 14 - 2021