Cov Chaw Tsim Tshuaj rau Thermocol Moulding tshuab - Cov Vaj Huam Sib Zoo Zoo Tsim Kho Kev Tsim Vaj Huam Sib Luag Tshuab - Dongshen

Cov Chaw Tsim Tshuaj rau Thermocol Moulding tshuab - Cov Vaj Huam Sib Haum Zoo Tsim Kho Kev Tsim Vaj Huam Sib Luag Tshuab - Dongshendetail:

Lub hauv paus rau phau ntawv

Nta

Zoo tsim nyog tsim vaj vaj vaj huam sib luag nrog kev tswj tuab thiab muaj txiaj ntsig zoo thiab muaj zog wyriling ib qho khoom ntawm cov khoom lag luam zoo. Piv cov kab vaj huam sib luag 3D vaj huam sib luag tshuab, peb txoj kev tsim vaj huam sib luag tshuab tau muaj ntau tshaj li kab rov tav hom kab rov tav.

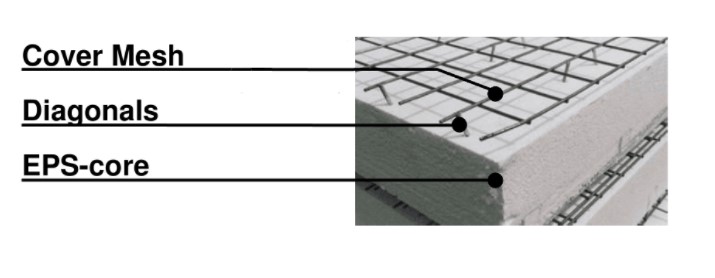

Vaj huam sib luag tshwj xeeb yog cov vaj huam sib luag tsim kho tsev muaj cov nta raws li hauv qab no:

Vaj huam sib luag tshwj xeeb yog cov vaj huam sib luag tsim kho tsev muaj cov nta raws li hauv qab no:

1. Nws tuaj yeem tsim tau ob qho tib si - Txheej thiab ob npaug - Txheej 3D Panels rau sab nraud phab ntsa rwb thaiv tsev thiab muaj peev xwm muaj peev xwm.

2. Nws muaj cov kab ke sib xyaw rau cov khoom siv kom ntseeg tau tias nws txoj haujlwm ruaj khov, muaj kev ntseeg siab thiab lub neej ntev ntev.

3. Cov hlau hlau feter ntawm cov khoom siv hom muaj lub pneumatic thiab lub tshuab vuam tsis yooj yim.

4. Cov Hlau Hlau feed ntawm cov khoom b hom muaj tus pneumatic clamping ntaus ntawv thiab lub vuam kaum tau tuaj yeem hloov kho.

5. Tus Mahine yooj yim rau kev khiav lag luam thiab saib xyuas nrog tus kheej - Kev kuaj tus kheej thiab tsis siv neeg lub tswb.

| Qho ntev | 2000mm-6000mm lossis Mekas |

| Qhov dav | 1200mm (ntsug hlau chaw loj), Mesh loj dua 50mm × 50 hli |

| Galvanized Kab Hlau | Φ2.5 hli - φ3.0 hli; |

| Vuam Ceev (Peev) | 50Step / Min-55 Kauj ruam / min; 150m² / h; |

| Vuam zoo | Meshen Welding Missed Ratio ≤8 ‰, Solder Koom Tes Muaj Zog: ≥1000n / Taw tes Mesh Qhov loj me no kev sib txawv ± 1mm cov kev sib txawv sib txawv 3m ≤3mm / m; |

Rooj plaub

Related video

Khoom Qhia:

Phau Ntawv Qhia Yam Khoom Qhia Txog:

Peb ntseeg tau tias kev sib koom tes ua ke, kev lag luam ntawm peb yuav coj peb kev sib nrig sib. Peb tuaj yeem lav koj cov khoom lag luam zoo thiab muaj kev sib tw muaj nuj nqi tsim kev tsim khoom lag luam rau thermocol tshuab moulding tshuab - Lub vaj huam sib luag zoo tsim nyog tsim kho vaj tsev tshuab - Dongshen, xws li cov khoom lag luam zoo, lub tuam txhab ua kom txhua yam kom muab peb cov neeg siv khoom zoo tshaj plaws thiab cov khoom lag luam zoo tshaj plaws. Peb cog lus tias peb yuav ua lub luag haujlwm mus txog thaum kawg thaum peb cov kev pabcuam pib.