Hoobkas - Npaj EPS Txhaj Tshuaj Molding Tshuab

Khoom cov tsis muaj cov khoom lag luam tseem ceeb

| Yam | Ib yam | FAV1200 | Fav1400 | Fav1600 | Fav1750 |

|---|---|---|---|---|---|

| PWM NTIM | mm | 1200 * 1000 | 1400 * 1200 | 1600 * 1350 | 1750 * 1450 |

| Max Cov Khoom Muaj Peev Xwm | mm | 1000 * 800 * 400 | 1200 * 1000 * 400 | 1400 * 1150 * 400 | 1550 * 1250 * 400 |

| Txoj hlab ntsha | mm | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 |

| Chav tau | Kg / kev voj voog | 5 ~ 7 | 6 ~ 9 | 7 ~ 11 | 8 ~ 12 |

| Nce Siab | MPa | 0.5 ~ 0.7 | 0.5 ~ 0.7 | 0.5 ~ 0.7 | 0.5 ~ 0.7 |

| Qho hnyav | Kg | 5000 | 5500 | 6000 | 6500 |

Cov Khoom Lag Luam Khoom Tshwj Xeeb

| Kev qhia tshwj xeeb | FAV1200 | Fav1400 | Fav1600 | Fav1750 |

|---|---|---|---|---|

| Cua Txias Dej | 45 ~ 130 kg / kev voj voog | 50 ~ 150 Kg / Kev voj voog | 55 ~ 170 kg / kev voj voog | 55 ~ 180 kg / kev voj voog |

| Kev Siv Cua Hluav Taws Xob | 1.5 ML / CXWM | 1.8 ML / CLEXLE | 1.9 ML / CLEXLE | 2 m³ / voj voog |

Cov khoom lag luam tsim khoom

Kev tsim khoom lag luam ntawm EPS txhaj tshuaj moulding machine ua raws cov txheej txheem ua kom tiav kom ua haujlwm tau zoo thiab qhov zoo. Cov txheej txheem pib nrog ua ntej - Kev nthuav dav ntawm EPS Beads los ntawm kev nthuav dav ua ntej - Qhov chaw uas lawv tau teeb tsa qhov loj me kom nce ntxiv thiab npaj lawv kom loj hlob. Ua raws li ua ntej - Kev nthuav dav, cov khoom tau thauj mus rau EPS txhaj tshuaj molding tshuab ntawm kev cia siab thiab sau rau hauv cov pwm kab noj hniav. Hauv cov pwm no, lub EPS dua li nthuav tawm cov pa hauv qab kev tswj hwm uas ua rau cov hlaws dai kom nthuav ntxiv thiab fuse, tsim qhov xav tau. Advanced chav, cua txias, thiab cov hlab kub hauv peb lub tshuab, txhawb nqa los ntawm kev tswj ruaj khov, ua kom muaj kev tsim khoom zoo thiab ua haujlwm. Raws li qhov tseem ceeb ntawm kev rov ua dua tshiab, kev tsim kho kom pom tseeb rau kev txo qis cov khib nyiab thiab txhim kho cov ntaub ntawv rov siv dua, ua ntej lub neej tom ntej rau EPS tsim.

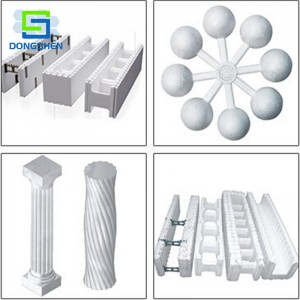

Khoom Daim Ntawv Thov

EPS Txhaj Tshuaj Moulding Machine yog PIVOTAL hauv ntau yam kev lag luam vim lawv cov versatility thiab efficiency. Nyob rau hauv lub hnab ntim khoom, lawv tau siv los tsim Cushioning ntsiab rau cov khoom hluav taws xob tsis yooj yim, ua kom pom kev nyab xeeb thiab xa khoom. Hauv kev tsim kho, vim lawv cov khoom siv rwb thaiv tsev zoo heev, lawv pom cov ntawv thov hauv cov khoom sib xyaw ua ke, ua rau lub zog ua kom muaj txiaj ntsig. Kev lag luam automotive los ntawm EPS rau nws cov kev cuam tshuam kev puas tsuaj, siv nws hauv kev nyab xeeb cov khoom siv kaus mom hlau thiab pob tw tsheb. Raws li kev lag luam sib cav rau kev ruaj khov thiab cov tswv yim tsim khoom zoo, cov tswv yim zoo ntawm EPS kev txhaj tshuaj molding tshuab ua rau lawv tsis tseem ceeb hauv cov chaw ua haujlwm tam sim no.

Khoom tom qab - muag kev pabcuam

Peb cov kev muaj txhij txhua tom qab kev pabcuam muag kom ntseeg tau tias koj lub Hoobkas tau txais kev txhawb nqa txuas ntxiv - Kev yuav. Peb muab kev saib xyuas ib txwm, software hloov tshiab, thiab kev cob qhia kev cob qhia rau cov neeg ua haujlwm Hoobkas kom ua rau lub TSHUAB ua haujlwm zoo thiab muaj sia. Yog tias txhua qhov teeb meem, peb pab pawg tau npaj txhij los muab ob qho chaw taws teeb thiab cov kev pab cuam.

Cov Tsheb Thauj Mus Los

Peb xyuas kom peb EPS txhaj tshuaj molding tshuab thauj nyab xeeb kom nyab xeeb thiab ua tau zoo rau koj lub Hoobkas chaw, nrog cov tsheb thauj khoom, tuav kev txhawb nqa. Customized ntim cov kev daws teeb meem tsawg kawg kev pheej hmoo ntawm kev puas tsuaj thaum pib.

Cov khoom lag luam zoo

- Customizable:Haum qauv thiab ntau lawm muaj peev xwm kom haum lub Hoobkas yuav tsum tau ua.

- Tus nqi - Siv tau zoo:Tsim los rau kev ua haujlwm siab, txo cov nqi kev ua haujlwm.

- Kev tswj hwm cov tshuab:Txhim kho cov kev ntsuas thiab kev tswj hwm ua haujlwm.

- Ib puag ncig cov neeg:Txhawb nqa rov ua dua tshiab thiab cov khib nyiab me me.

Khoom Muag FAQ

- EPS Txhaj Tshuaj Moulding Machine tau pab tau kuv lub Hoobkas?EPS Txhaj Tshuaj Moulding Machine Muaj Siab Precision, Kev Ua Haujlwm, Thiab Kev Tsim Khoom, Qhov Tseem Ceeb Rau Lub Hoobkas Xav Tau Zoo.

- Nws puas yooj yim los tswj EPS txhaj tshuaj molding tshuab?Yog lawm, peb lub tshuab tau tsim rau kev yooj yim txij nkawm, nrog tus neeg siv - cov phooj ywg interfaces rau kev kuaj mob thiab kev daws teeb meem.

- Lub tshuab puas tuaj yeem kho rau kev siv lub Hoobkas tshwj xeeb?Kiag li, peb tuaj yeem hloov lub tshuab tsim qauv thiab kev teeb tsa kom phim cov kev tsim khoom uas yuav tsum tau ntawm koj lub hoobkas.

- Yuav ua li cas yog lifespan ntawm EPS txhaj tshuaj molding tshuab?Nrog rau kev tu xyuas kom tsim nyog, peb cov tshuab ua tau kom kav ntev, xa cov kev ua tau zoo rau kev nce qib kaum xyoo hauv Hoobkas.

- Zog zog - txuag tau cov tshuab no?Peb cov tshuab sib xyaw ua ke rau cov thev naus laus zis los txo kev siv hluav taws xob tsawg dua thaum ua haujlwm loj heev hauv lub hoobkas.

- Dab tsi kev cob qhia nrog lub tshuab?Peb muaj cov kev kawm qhia meej meej kom ntseeg tau tias koj cov neeg ua haujlwm hauv lub Hoobkas tau ua haujlwm tau zoo thiab tswj cov cuab yeej siv.

- Tom qab cov muag khoom lag luam ua haujlwm li cas?Peb tom qab - Cov Khoom Muag Khoom suav nrog kev saib xyuas kev saib xyuas ib txwm, software hloov tshiab, thiab kev txhawb nqa kev ua haujlwm kom ntseeg tau tias kev ua haujlwm zoo.

- Cov ntaub ntawv dab tsi yuav siv tau rau EPS Txhaj Tshuaj Molding Tshuab?Lub tshuab yog qhov zoo rau cov EPS cov ntaub ntawv, muab rau ntau yam kev tsim khoom lag luam.

- Lub tshuab puas tuaj yeem ua haujlwm ntau lawm?Yog lawm, peb cov tshuab tsim rau high - volum ntau lawm, catering rau loj - cov cav Hoobkas yuav tsum muaj peev xwm ua tau zoo.

- Yuav ua li cas yog tias peb xav tau cov khoom seem?Cov khoom seem yog npaj tau yooj yim thiab tuaj yeem xa tawm sai sai rau txo qis downtime hauv koj lub hoobkas.

Khoom Kub Khoom Kub

- Lub neej yav tom ntej ntawm Cov Chaw Tsim Tshuaj nrog EPS Txhaj Tshuaj Molding MachineNrog kev nce qib hauv thev naus laus zis, EPS txhaj tshuaj molding yog lub tsa suab li cas thiaj li ua haujlwm. Lawv cov txiaj ntsig thiab precision yog enable cov tuam txhab los tsim cov khoom lag luam siab los ua cov khoom lag luam siab, raug nqi - cov khoom lag luam zoo thaum txo cov khib nyiab. Raws li muaj kev coj ua kom ruaj khov ua qhov tseem ceeb, cov tshuab no hloov kho rau ib puag ncig - Cov ntaub ntawv ua phooj ywg rau lawv raws li cov cuab tam tseem ceeb hauv kev tsim khoom niaj hnub no.

- Txhim Kho Cov Kev Txhim Kho Hoobkas Nrog Kev Cai EPS SolutionsCov ntaub ntawv kev siv EPS txhaj tshuaj molding tshuab ua pov thawj lub zog tseem ceeb hauv kev tsim khoom. Los ntawm kev tso cai rau lub tshuab customization, peb xyuas kom meej tias koj cov kab ntau lawm yog ua kom tau raws li cov kev xav tau thaum muaj kev tswj hwm cov khoom lag luam zoo. Qhov kev sib txuas lus no tsis tsuas yog cov haujlwm cub tab sis kuj tseem txo cov khoom pov tseg, qhia cov versatility ntawm EPS kev siv tshuab hauv cov chaw ua haujlwm hauv Hoobkas.

- Kev Siv Kom Muaj Peev Xwm Hauv Hoobkas Ntau Lawm nrog EPS TshuabRaws li kev txhawj xeeb ib puag ncig sawv, lub chaw ua haujlwm tau tig mus rau EPS txhaj tshuaj molding tshuab rau lawv cov khoom siv thiab lub zog ua haujlwm. Cov tshuab no tsis tsuas yog txo cov nqi tsim khoom tab sis kuj tseem ua txoj hauv kev hauv kev ua haujlwm hauv lub Hoobkas los ntawm kev txhawb nqa cov khoom siv ua rov qab thiab txo cov hneev taw ntxiv.

- Tus nqi - Kev tsim tau zoo nrog EPS txhaj tshuaj molding tshuabLos ntawm kev sib xyaw EPS txhaj tshuaj molding tshuab, Hoobkas tuaj yeem txiav cov nqi ntau lawm. Cov tshuab 'ua tau zoo siv cov ntaub ntawv thiab lub zog txhais ua cov nuj nqis txo qis, ua kom cov tuam txhab ua kom rov ua haujlwm rau lwm lub Hoobkas txhim kho thiab kev txhim kho.

- EPS Txhaj Tshuaj Moulding Machine: Tus qaumteb dua ntawm cov chaw ua haujlwm niaj hnubCov tshuab no sawv ntsug raws li kev ua tim khawv txog niaj hnub kev lag luam. Lawv sib koom ua ke rau hauv cov neeg ua haujlwm hauv tsev ua ntej ua ntej cov instrumental hauv kev tsim cov khoom siv, cov txheej txheem ntau lawm, pab tau ntau dua cov khoom xav tau raws li qhov xav tau zuj zus thiab nrawm.

- Revolutioning cov chaw hauv EPS thev naus laus zisTsoos kev tsim qauv paradigms yog nrawm zuj zus nrog kev tawm ntawm EPS txhaj tshuaj molding tshuab. Cov tshuab no yog enabling cov teeb meem los pivot ntawm ntau ntau yam, cov kab tsim khoom lag luam, ua rau lub neej tom ntej ntawm kev tsim khoom lag luam.

- Lub Luag Hauj Lwm Ntawm EPS Txhaj Tshuaj Molding Machine Hauv Ntiaj Teb RaugThoob ntiaj teb, cov teeb tsa EPS txhaj tshuaj EPS txhaj tshuaj molding tshuab ua kom PACE nrog cov qauv tsim khoom thoob ntiaj teb. Kev hloov pauv no tsis yog txhim kho cov peev xwm ntau lawm tab sis tseem tso cov teeb meem ntawm qhov ua ntej ntawm kev tsim tawm kev tsim tawm tshiab.

- Lub Hoobkas Taus thiab EPS Txhaj Tshuaj Molding MachineFactories saib ntsuas kom nrawm nrawm nrhiav EPS txhaj tshuaj molding tshuab tsis tau. Lawv cov tawv nqaij tso tawm cov chaw ua haujlwm kom nthuav cov kab ntau lawm yam tsis muaj kev cuam tshuam zoo rau kev loj hlob sai thiab kev yoog raws.

- Txhim Kho Lub Hoobkas Layout Nrog EPS TshuabEPS Txhaj Tshuaj Moulding Machine Yuav tsum tau muaj kev xav txog kev npaj phiaj xwm Hoobkas, kev ua tau zoo tshaj plaws thiab kev tsim tau. Qhov kev ua tau zoo no ua rau cov haujlwm seamless, kom ntseeg tau tias cov chaw ua haujlwm tseem muaj kev sib tw thiab ua haujlwm.

- Sib xyaw EPS Txhaj Tshuaj Molding Machine Rau Hauv Lub Hoobkas Ua HaujlwmKev sib xyaw ua ke yog qhov tseem ceeb rau kev shoption shoption of EPS txhaj tshuaj molding tshuab hauv Hoobkas. Los ntawm poligning cov tshuab no nrog cov haujlwm ua haujlwm uas twb muaj lawm, cov chaw ua haujlwm tuaj yeem ua tiav kev ua tiav ntau dua thiab tso zis, teeb tsa cov qauv tshiab hauv kev ua haujlwm Hoobkas.

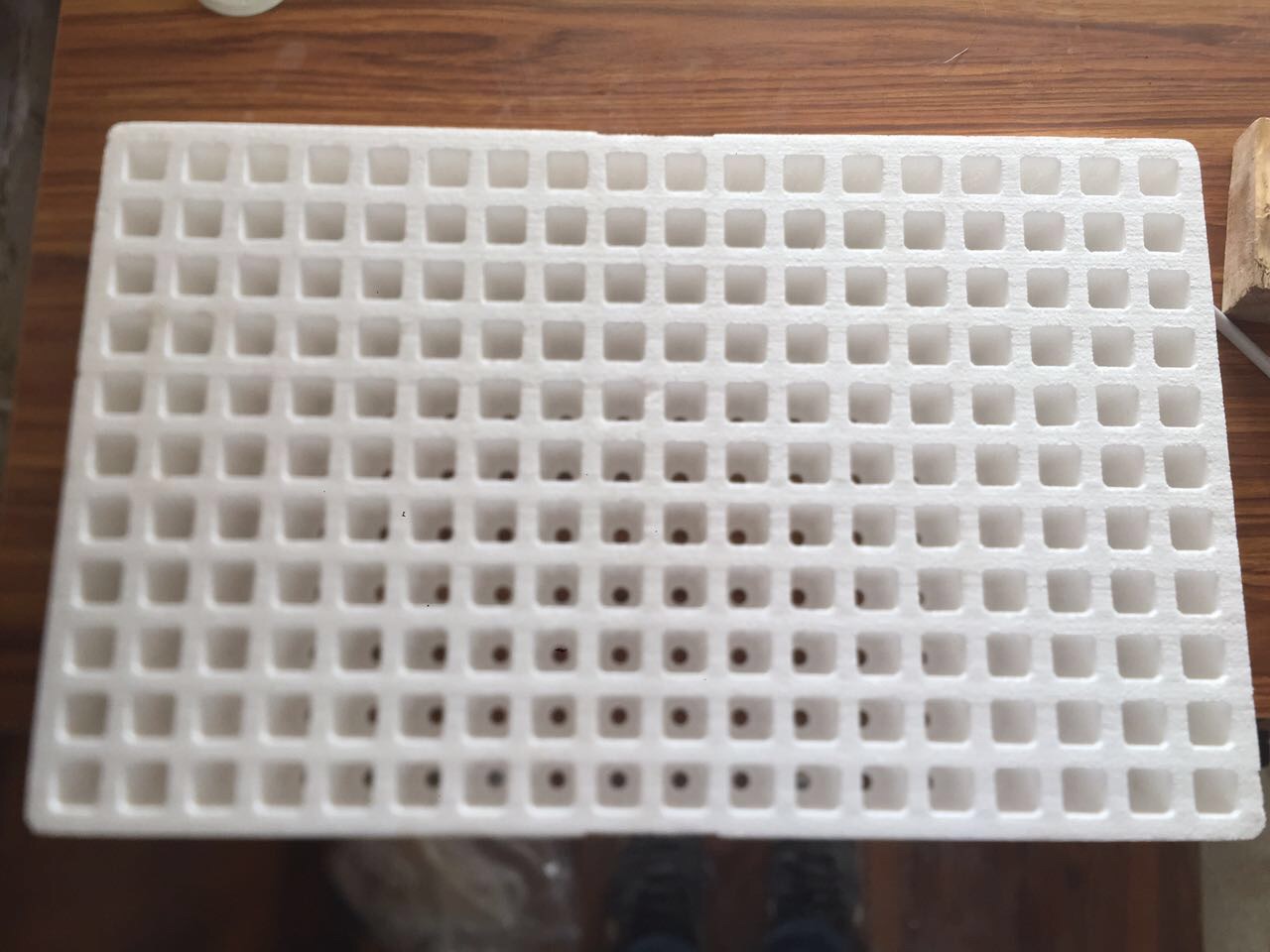

Duab piav qhia

Tsis muaj cov lus piav qhia rau cov khoom no