Tshwj Xeeb Cov Txiv Hmab Txiv Ntoo Lub Thawv Pwm: EPS Puv Phom Rau Cov Khoom Siv Kom Zoo Moulding

Dongshen nthuav tawm EPS puv ntxiv rau koj cov block moulding tshuab, zoo meej crafted ua lub thawv txiv hmab txiv ntoo koj tau tshawb. Peb nkag siab qhov tseem ceeb ntawm kev ntseeg tau, muaj txiaj ntsig, thiab siv tau molding ntaus ntawv hauv koj kab ntau lawm. Thiab yog vim li cas peb thiaj qhia koj rau peb qhov kev tsis sib haum xeeb EPS puv phom. Cov cuab yeej zoo tshaj plaws los nrog cov qauv yooj yim, ua rau nws tsis yog tus neeg siv khoom - tus phooj ywg tab sis kuj tseem ceeb yooj yim los tswj. Peb ntseeg tias muaj kev daws teeb meem uas tsis ntxiv cov nyom tsis tsim nyog rau koj txoj haujlwm. Li no, peb lub EPS ntim phom, koj lub thawv txiv hmab txiv ntoo zoo tagnrho ua rau koj ua haujlwm, kom koj cov haujlwm ua rau koj cov haujlwm txhua hnub. Peb lub thawv txiv hmab txiv ntoo pwm ua kom cov khoom siv tau txais yuav cov nyhuv rov qab, yog li txhim kho kev ua haujlwm ntawm koj cov txheej txheem ntau lawm. Cov ntsiab lus tseem ceeb no tshwj xeeb tshaj plaws ntawm cov teeb meem tawg paj tawg, qhov teeb meem uas muaj cov tshuab uas tsis tshua muaj siab dua. Los ntawm averting qhov no, peb ua kom koj cov khoom lag luam zoo tseem tsis tau pom, tuav kom tsis tsuas yog koj cov qauv tab sis cov qauv ntawm koj cov neeg siv khoom ib yam nkaus.

Yav dhau los:EPS Txiv Hmab Txiv Ntoo Lub thawv pwm Tom ntej:EPS Puv Phom Rau Cov Qauv Moulding Tshuab

Ua nrog versatility ntawm nws cov tub ntxhais, peb txiv hmab txiv ntoo pwm yog haum rau txhua hom thaiv MACHINE. Qhov no tau txais qhov ua kom koj tsis tuaj yeem ntsib kev txwv raws li kev sib raug zoo. Txawm hais tias koj nyob hauv kev lag luam khoom noj khoom haus, tsim khoom lag luam lossis chaw ntim khoom, qhov no yog cov txiv hmab txiv ntoo lub thawv uas yuav xa cov txiaj ntsig txhua zaus, txhua zaus. Xaiv peb qhov tshwj xeeb EPS pilling phom rau koj thaiv cov tshuab moulding. Tsa cov khoom zoo ntawm koj cov khoom lag luam, xyaum koj cov txheej txheem thiab txaus siab rau cov txiaj ntsig zoo heev peb yuav tsum muaj. Nrog Dongshen EPS Puv Phom, koj yuav hloov pauv txoj kev uas koj tsim, ua kom zoo sib xws, ua kom zoo sib xws, ua kom zoo thiab kev ntseeg tau. Ntseeg peb kom muab koj cov txiv ntoo zoo tshaj plaws pwm rau qhov kev thaiv tshwj xeeb moulding txheej txheem.

Khoom Paub meej

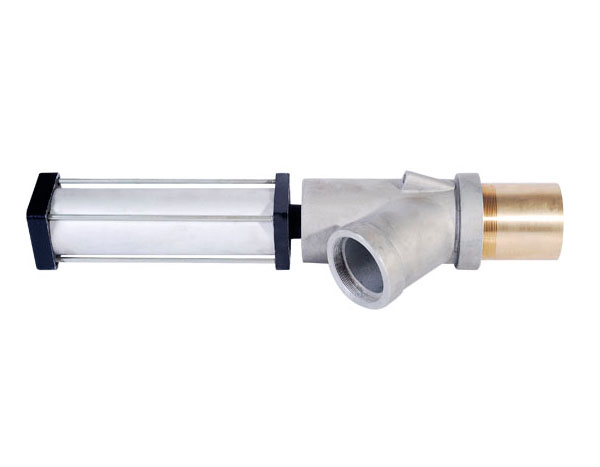

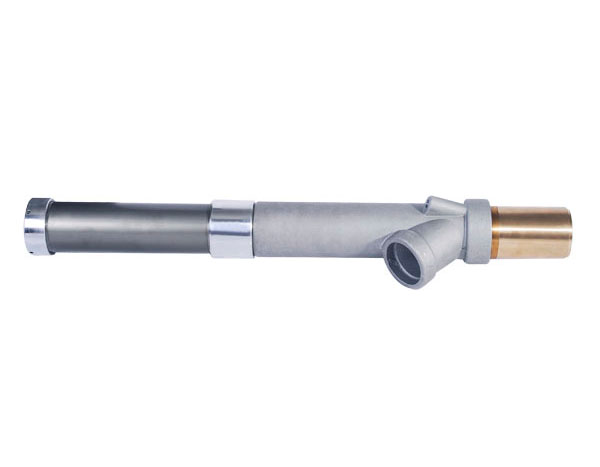

EPS Cov Khoom Siv Hluav Taws Xob yog siv kom phim EPS thaiv cov nyhuv, cov khoom lag luam zoo tau ruaj khov, thiab haum rau txhua hom thaiv cov cav. Cov kev qhia tshwj xeeb ntawm cov phom tau tuaj yeem kho tau raws li cov neeg siv khoom xav tau.

Sib nrug los ntawm hom kev sib sau ua ke, peb tseem muaj EPS sib sau phom rau EPS puab cov tshuab moulding tshuab.

Txais tos koj tiv toj ncaj qha yog tias koj muajKev nug.

Peb Eps Pwm Nta

Lub ntsiab kev tsis sib xws

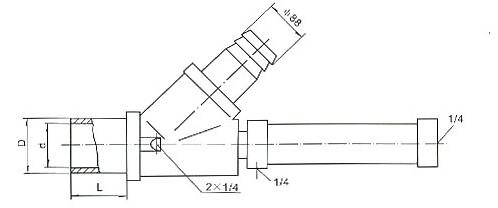

| Me me | D | d | L | Lub tog raj kheej taub | Hais txog |

| 70 | 53 | 100 | 63 | Ib qho tawg yeeb nkab interface rau pub 1/4 | |

| 100 | 80 | 100 | 80 | Ob lub moj tej tawg PIPES interface rau pub 1/4 |

Rooj plaub

Txaus pub

Kev Ua Haujlwm

Related video

Ua nrog versatility ntawm nws cov tub ntxhais, peb txiv hmab txiv ntoo pwm yog haum rau txhua hom thaiv MACHINE. Qhov no tau txais qhov ua kom koj tsis tuaj yeem ntsib kev txwv raws li kev sib raug zoo. Txawm hais tias koj nyob hauv kev lag luam khoom noj khoom haus, tsim khoom lag luam lossis chaw ntim khoom, qhov no yog cov txiv hmab txiv ntoo lub thawv uas yuav xa cov txiaj ntsig txhua zaus, txhua zaus. Xaiv peb qhov tshwj xeeb EPS pilling phom rau koj thaiv cov tshuab moulding. Tsa cov khoom zoo ntawm koj cov khoom lag luam, xyaum koj cov txheej txheem thiab txaus siab rau cov txiaj ntsig zoo heev peb yuav tsum muaj. Nrog Dongshen EPS Puv Phom, koj yuav hloov pauv txoj kev uas koj tsim, ua kom zoo sib xws, ua kom zoo sib xws, ua kom zoo thiab kev ntseeg tau. Ntseeg peb kom muab koj cov txiv ntoo zoo tshaj plaws pwm rau qhov kev thaiv tshwj xeeb moulding txheej txheem.