Tshawb nrhiav Dongshen lub Revolutionary Styrofoam granulator rau EPS Ua npuas ncauj Thaiv Ntau Lawm

Khoom Paub meej

Nthuav dav polystyrene fooam thaiv kev siv tshuab yog siv los ua EPS thaiv, tom qab ntawd txiav rau cov ntawv txheeb rau tsev rwb thaiv tsev lossis ntim khoom. Cov khoom nrov ua los ntawm EPS cov ntawv txheeb yog EPS Sandwich Panels, sab hauv thiab sab nraud phab ntsa rwb thaiv tsev panels, ntim iav iav ntim khoom thiab lwm yam.

Nthuav dav polystyrene fooam thaiv kev siv lub tshuab yog qhov tsim nyog me me thov thiab qis dua kev tsim khoom, nws muaj kev lag luam EPS tshuab. Nrog cov thev naus laus zis tshwj xeeb, peb nthuav dav polystyrene fooam thaiv kev siv tshuab tuaj yeem ua rau 4G / l ntom block, thaiv yog ncaj thiab zoo.

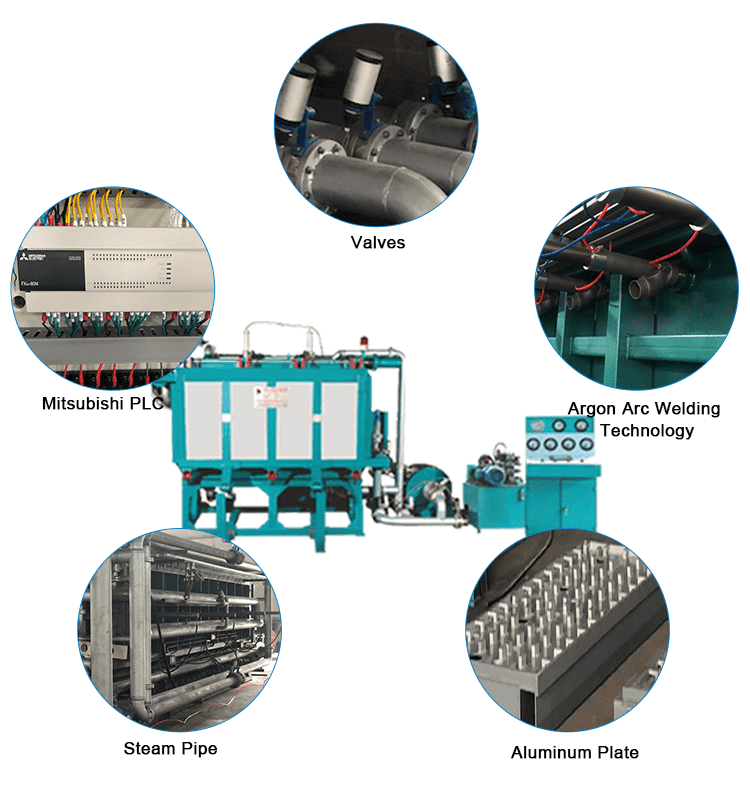

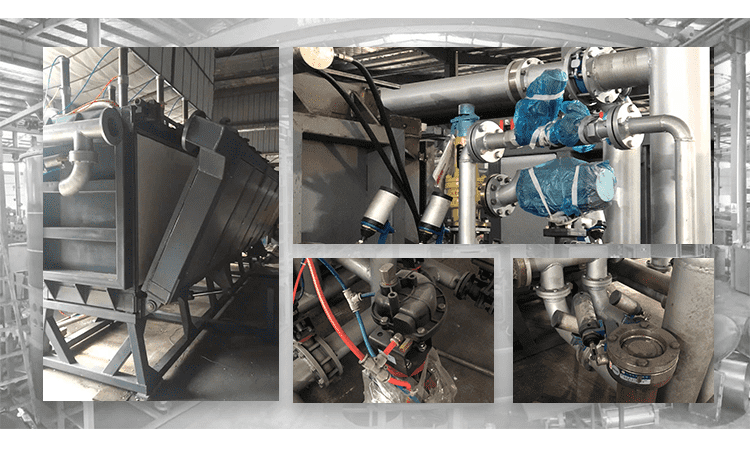

Tshuab ua tiav nrog lub cev loj, tswj lub thawv, blower, hnyav, system thiab lwm yam.

Cov yam ntxwv tseem ceeb

1. Lub tshuab adopishi plc thiab winview top tshuaj ntsuam rau tsis siv neeg tuaj pwm, khoom siv, ua kom cua txias, kub thiab muab rhaub.

2. TSHUAB rau tag nrho rau cov panels yog los ntawm kev kho cua sov kom tso cov kev ntxhov siab rau kev siv tshuab loj, yog li ntawd tsis tuaj yeem ua rau kub thiab txias;

3. Cov Pwm Cav yog ua los ntawm tshwj xeeb alloy phaj nrog siab - kev ua haujlwm kub heev 5 hli, nrog teflon txheej rau yooj yim didoulding.

4. Lub tshuab teeb tsa siab - Siab Blower rau kev nqus cov khoom. Cua txias yog ua los ntawm kev cog lus huab cua los ntawm Blower.

5. Cov phiaj hlau yog los ntawm High - Kev Kho Kom Zoo Hlau Profile, los ntawm kev kho cua sov, muaj zog thiab tsis muaj deformation.

6. Ejection yog tswj los ntawm cov twj tso kua mis hydraulic, yog li txhua tus ejors lub laub thiab rov qab rau hauv tib lub nrawm;

Lub ntsiab kev tsis sib xws

Yam | Ib yam | Pb2000a | Pb3000a | Pb4000a | Pb6000a | |

Pwm kab noj hniav loj | mm | 2040 * 1240 * 630 | 3060 * 1240 * 630 | 4080 * 1240 * 630 | 6100 * 1240 * 630 | |

Thaiv loj | mm | 2000 * 1200 * 600 | 3000 * 1200 * 600 | 4000 * 1200 * 600 | 6000 * 1200 * 600 | |

Pa ncho | Qhov chaws nkag | Nti | Dn80 | Dn80 | DN100 | DN150 |

| Kev noj | Kg / kev voj voog | 18 ~ 25 | 25 ~ 35 | 40 ~ 50 | 55 ~ 65 |

| Nyem | MPa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 |

Compressed cua | Qhov chaws nkag | Nti | Dn40 | Dn40 | Dn50 | Dn50 |

| Kev noj | miv / kev voj voog | 1 ~ 1.2 | 1.2 ~ 1.6 | 1.6 ~ 2 | 2 ~ 2.2 |

| Nyem | MPa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 |

Tso kua mis | Chav Tshuaj | Nti | DN100 | DN150 | DN150 | DN150 |

Muaj peev xwm 15kg / m³ | Min / kev voj voog | 4 | 5 | 7 | 8 | |

Txuas load / Fais Fab | Kw | 6 | 8 | 9.5 | 9.5 | |

Zuag Tawm Ib Zos (L * h * w) | mm | 3800 * 2000 * 2100 | 5100 * 2300 * 2100 | 6100 * 2300 * 2200 | 8200 * 2500 * 3100 | |

Qho hnyav | Kg | 3500 | 5000 | 6500 | 9000 | |

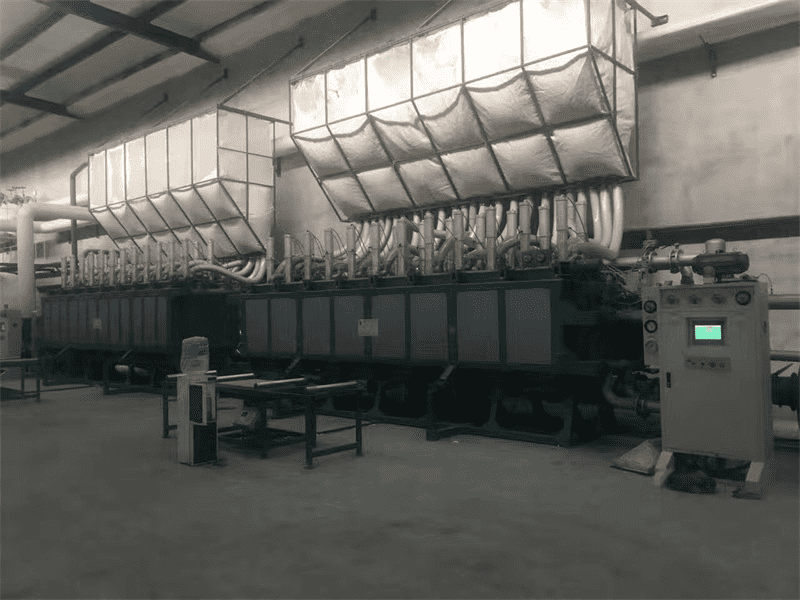

Rooj plaub

Related video

Using the Styrofoam Granulator is an incredible way to keep production costs down while enhancing output quality. Its ease of operation and maintenance further adds to the productivity of the process, making it an indispensable tool for any industry relying on EPS foam blocks. In conclusion, Dongshen's Styrofoam Granulator is not only a game-changer in the production of EPS foam blocks, but it is also a significant step towards developing more sustainable and efficient industrial processes. Relying on this machine means entrusting the production of your EPS foam blocks to a fast, reliable, and cost-effective solution, which ultimately leads to maximized productivity and profitability in your operations. Trust in Dongshen’s innovation to meet and exceed your industry's requirements.