Tuam Tshoj Pheej Yig Nqe EPS Resin Reactor - EPS Raw Khoom Cov Khoom Siv - Dongshen

Tuam Tshoj Pheej Yig Nqe EPS Resin Reactor - EPS Raw Khoom Cov Khoom Siv - Dongshendetail:

Ntsiab lus ntawm EPS(Nthuav dav polystyrene) Cov Khoom Siv Raw Khoom

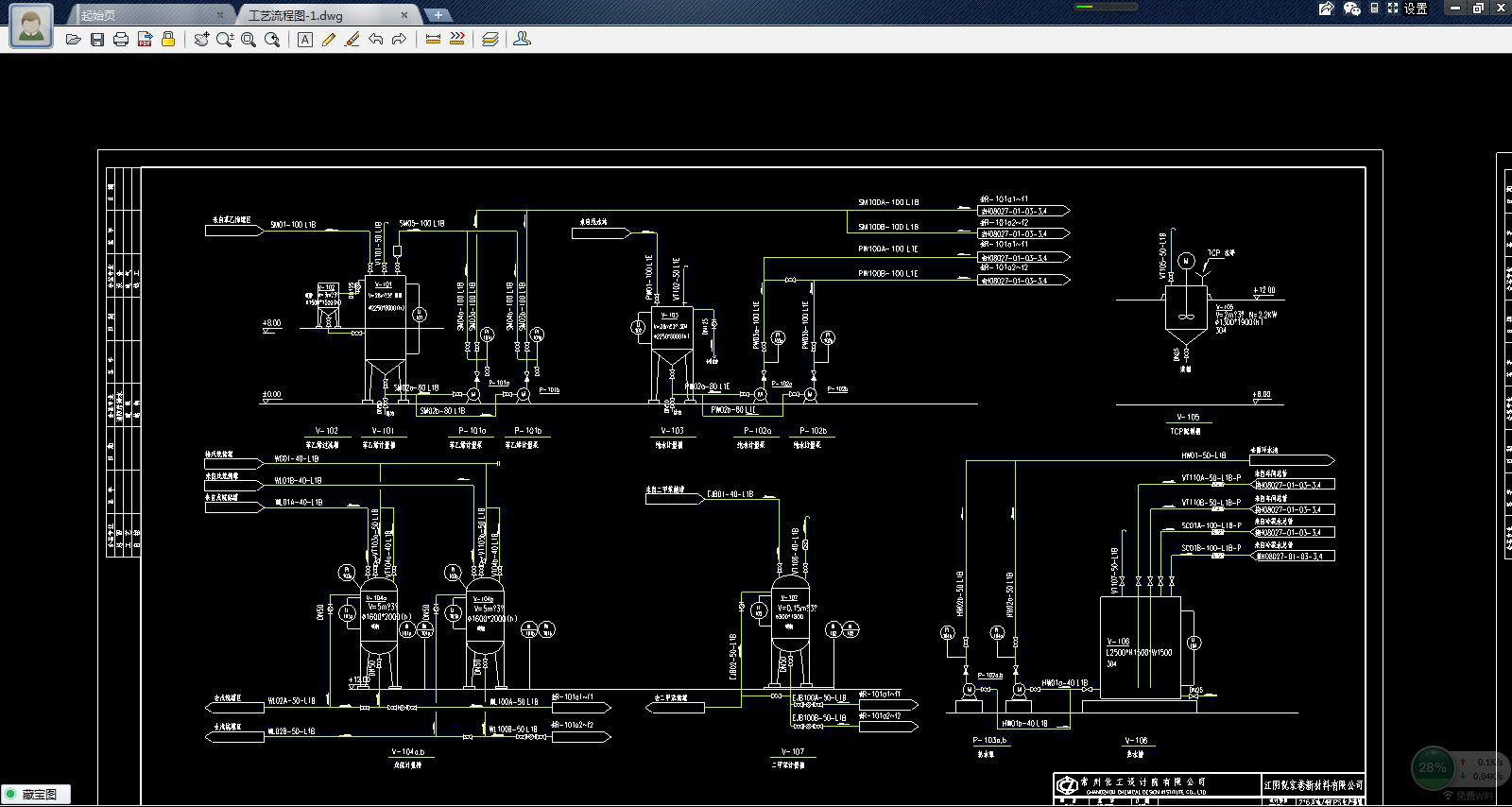

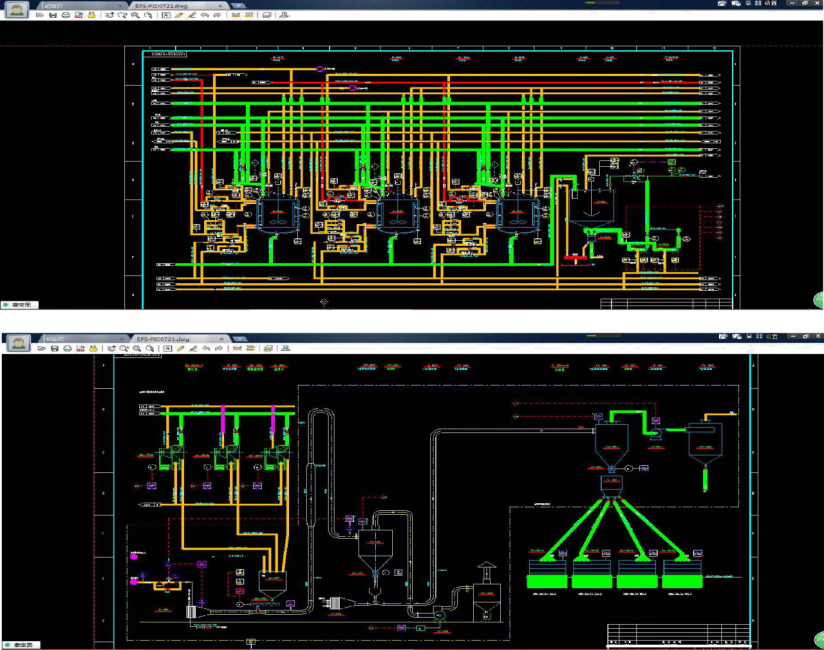

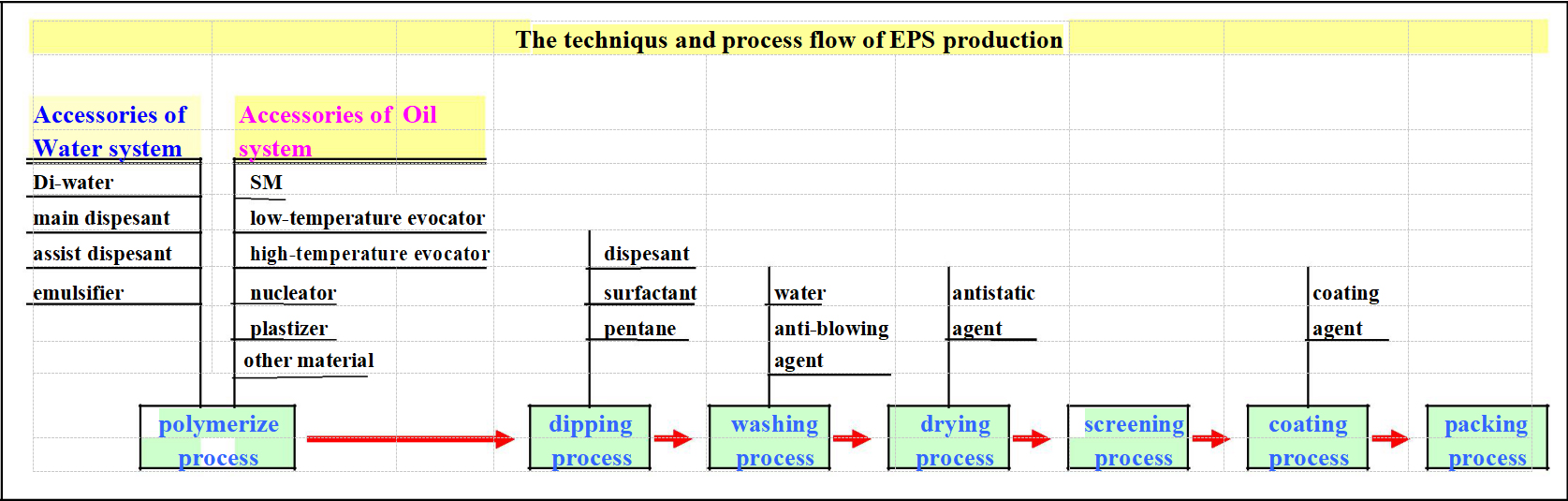

Txheej Txheem Flunge

Cov txheej txheem ntawm ib qho - theem qauv suav nrog polymerization, txias, ua kom txias, ntxuav, sieving, kev co kuaj, ntim. Lub sijhawm nruab nrab ntawm EPS ntau lawm yog 16 ~ 17 teev.

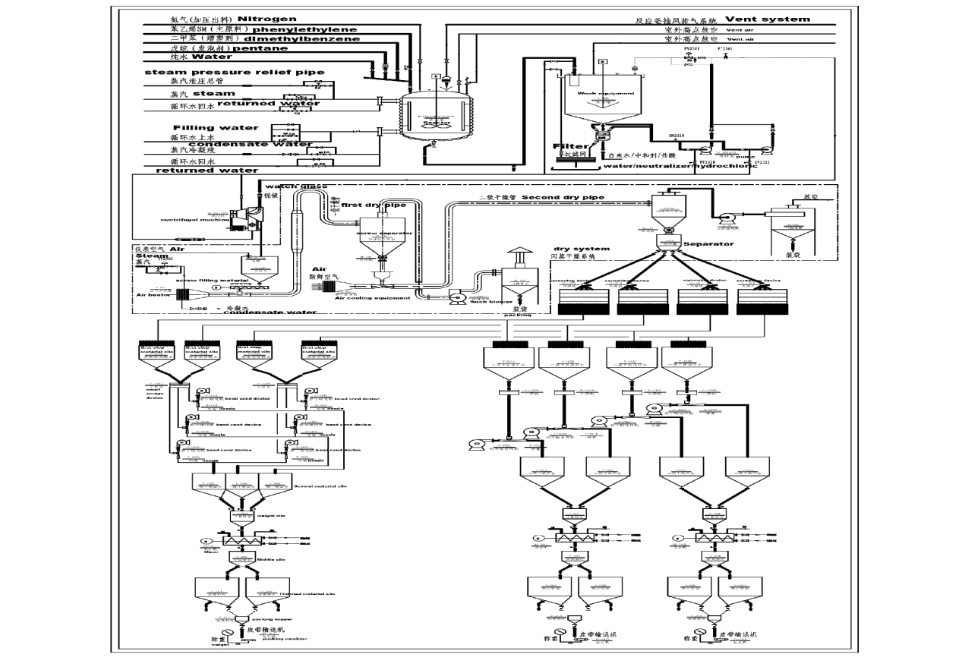

(1) polymerization thiab impregnation

Polymerization thiab impregnation yog proyessed hauv reactor. Nyob rau hauv qee qhov kev kub siab, SM yuav polymerize. Los ntawm comtinuous nplawm, sm yuav txuas ntxiv thiab txiav mus rau hauv ib daim hlab, tom qab ntawd comprosing sm roj tee nyob rau hauv dej vim tias sab ntuj siab. Nws muaj cov neeg khib nyiab tshem tawm hauv dej kom tsis txhob pob ua pob thiab txuas ua ke. Nyob rau hauv cov txheej txheem no lub zog cuam tshuam yuav tsum loj dua li lub zog txuas los xyuas kom meej qhov qis - Kub Polyerization.

Cov tshuaj tiv thaiv kev ua haujlwm tsawg - Kev ntsuas cov tshuaj tiv thaiv Polymnerization tau khiav hauv cov roj tso rau hauv cov tshuaj kub yuav coj mus rau hauv cov dej txias hauv cov txheej txheem clip. Txhawm rau tshem tawm cov cua sov nyob rau lub sijhawm, peb yuav tsum ua kom cov nquag ua haujlwm ntawm cov dej rov qab ua dua thaum lub sijhawm cov tshuaj tiv thaiv. Txwv tsis pub, qhov ntsuas kub nyob rau hauv cov reactor yuav dhau heev, uas ua rau cov tshuaj tiv thaiv nrawm thiab muaj txiaj ntsig viscosity.

Cov hlaws dai ntau lawm yog tswj hwm manually, thaum lub sij hawm, qhov ntsuas kub yuav tsum tau tswj kom raug kev zam loj, lwm yam, ntawm cov hlaws dai yuav yog widened. Lub sijhawm, feem ntau kev saib xyuas ntawm cov qauv yog qhov tseem ceeb los tswj qhov loj ntawm cov hlaws dai.

Los ntawm kev kho ntawm lub teeb hnyav caco3 thiab tcp, qhov loj ntawm cov hlaws dai tuaj yeem tswj tau.

DCS system yog siv rau kev tswj kom kub thaum lub sijhawm ua kom sov, polymerization, impregnation, siab - kub - thiab txias. Txhawm rau kom ntseeg tau tias kev nyab xeeb kev nyab xeeb, DCS system yuav tswj tau cov tshuaj uas cov tshuaj tiv thaiv kev kub ntxhov thiab lub sijhawm, thiab tswb nyob rau hauv tshaj - kub lossis muaj kev kub ntxhov.

Thaum tus nqi hloov dua siab tshiab ntawm SM ncav cuag kwv yees li 75% (li 5 txog 5 teev nyob rau hauv qhov kub tsis tu ncua), qee qhov ntau ntawm cov neeg sawv cev yuav tsum tau ntxiv. Tom qab tus impregnating thiab polymerization nyob rau hauv qee lub sij hawm thiab siab, peb tuaj yeem tau txais EPS Beads.

Lub tshuab sawv cev rau impregnation yog txhaj rau hauv kev ntsuas lub lauj kaub, thiab qhov hnyav los ntawm cov khoom siv hnyav. Tom qab cov txheej txheem siab - tempterature, thaum txias mus rau qhov ntsuas kub, cov khoom tuaj yeem rho tawm mus rau cov tank ntxuav.

(2) ntxuav

Lub impurities xws li dispersant thiab defloculates yuav tsum tau muab tshem tawm los ntawm kev ntxuav. Tom qab tu, EPS hlaws dai yuav qhuav los ntawm centrifugal lub cev qhuav dej kom tshem tawm feem ntau cov dej, thiab npaj rau kev ziab ntxiv.

Peb kuj tseem tuaj yeem siv de - Foaming tus neeg sawv cev kom tshem tawm impurities.

(3) Kom qhuav

Tom qab centrifugal lub cev qhuav dej, yuav muaj txog li 3% dej nyob rau ntawm EPS cov khoom lag luam yuav cuam tshuam rau cov khoom lag luam EPS (hauv cov txheej txheem ua kom qhuav, EPS Beads qhuav los ntawm huab cua kub. Tshuab los ntawm cua kub, lub ntug dej saum npoo ua cov pa hluav taws xob, thiab thawb cov pa hluav taws xob ntau dua los ntawm cov pa hluav taws kub Nyob rau hauv no txoj kev hlaws yuav qhuav.

Tom qab cua tshuab cua kom qhuav, cov hlaws dai yuav tsum tau txias los ntawm cua txias kom txo cov ntsiab lus dej, thiab npaj txhij rau kev tshuaj ntsuam. Txhawm rau tiv thaiv cov hluav taws xob txuam nrog hluav taws xob, tus neeg tiv thaiv tus neeg sawv cev yuav tsum tau ntxiv thaum ziab.

Lub tshuab ziab qhov kub yog tswj tau los ntawm DCS system.

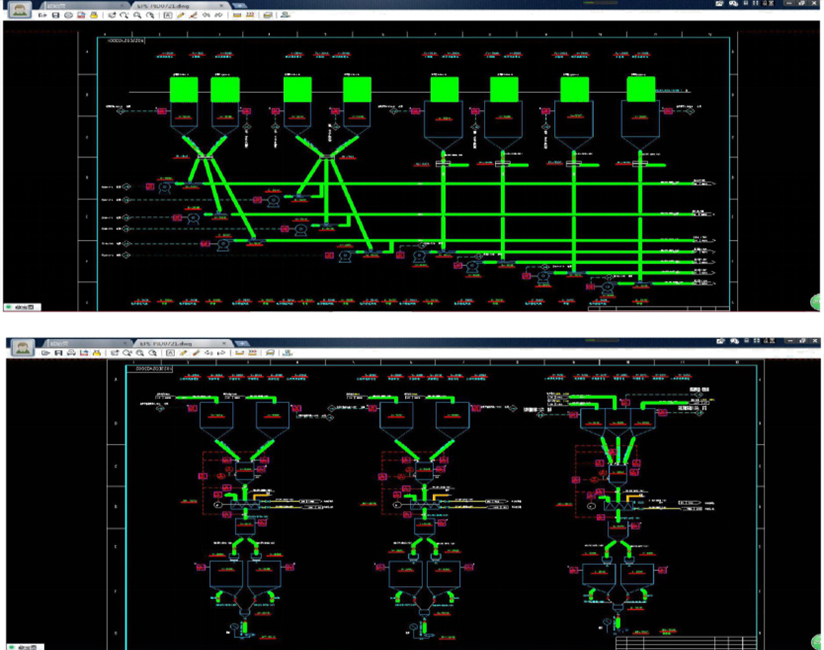

(4) tshuaj ntsuam

Qhov ntau thiab tsawg rau cov hlaws qhuav

(5) Txheej

Thaum lub sij hawm EPS ntau lawm, chaw cia khoom, tsheb thauj mus los, qhov kev khiav dim ntawm cov neeg sawv cev ntawm cov neeg sawv cev yog qhov tsis pom zoo. Yog tias ntau dhau los tus neeg sawv cev, muaj ntau yam teeb meem yuav tshwm sim, thiab tiv thaiv kev ua kom ntev, kev siv txheej txheem txheej ntawm tus neeg sawv cev ntawm EPS yog qhov tseem ceeb.

(6) pob

Pob EPS hlaws dai raws li kev sib txawv. Lub pob txheem hnyav yog 25kg.

Lub hom phiaj ntawm kev ntim khoom siv: kev thauj mus los, zam kev khiav dim ntawm lub caij lav lub sij hawm.

EPS Daim Ntawv Qhia

Rooj plaub

Khoom Qhia:

Phau Ntawv Qhia Yam Khoom Qhia Txog:

Nws yog tiag tiag yog peb lub luag haujlwm kom txaus siab koj cov kev xav tau thiab pab koj zoo rau koj. Koj cov nqi zog ua tiav yog peb cov nqi zog tshaj plaws. Peb nyob nraum yos hav zoov rau koj daim tshev rau kev sib koom tes kev txhim kho forchina pheej yig tus nqi ePS rein reactor - EPS Raw Khoom Siv Khoom Siv - Dongshen, cov khoom yuav muab rau thoob plaws lub ntiaj teb, cov khoom lag luam tau dhau los ntawm cov ntawv pov thawj hauv tebchaws thiab tau txais txiaj ntsig zoo hauv peb kev lag luam tseem ceeb. Peb cov kws tshaj lij engineering yuav feem ntau npaj tau los pab koj rau kev sib tham thiab tswv yim. Peb tau tuaj yeem xa koj cov nqi them rau koj cov qauv pub dawb kom tau raws li koj cov specs. Tej zaum zoo tshaj plaws yuav tau ua los xa koj cov kev pabcuam zoo tshaj plaws thiab cov kev daws teeb meem. Yuav tsum yog tiag tiag koj txaus siab rau peb lub tuam txhab thiab cov kev daws teeb meem, thov ua rau peb xa email lossis hu rau peb kom ncaj. Kom muaj peev xwm paub txog peb cov kev daws teeb meem thiab kev lag luam. A ntxiv, koj yuav tuaj yeem tuaj rau peb lub Hoobkas kom pom nws. Peb yuav niaj hnub txais tos qhua los ntawm thoob plaws lub ntiaj teb mus rau peb lub tuam txhab. o Tsim kev lag luam lag luam. elations nrog peb. Koj yuav tsum muaj kev ywj pheej uas tham nrog peb rau lub koom haum. Nd peb ntseeg tias peb yuav qhia qhov zoo tshaj plaws kev ua lag luam kev ua si nrog txhua tus tub lag luam.