ʻO nā loiloi maikaʻi loa e hoʻopaʻa i nā hoʻonāʻana o nā hoʻoponoponoʻana mai ka alakaʻi e nā mea hana ejector, dongshen

Nā 'Detailslelo kiko'ī

Hoʻopiliʻo Polystyrene i nā mīkini Willing Wireing me ka hakahaka e nā mīkini eps maikaʻi e hana i nā poloka eps. Hiki keʻokiʻia nā poloka eps no nā pale no ka hoʻopaʻaʻana a iʻole ka paleʻana. Nā huahana kaulana i hanaʻia mai nā'āpana eps eps ipswelich, 3d palt, inner

Hoʻopiliʻo Polystyrene poloka i nā mīkini hoʻolimalima me nā hua hoʻolimalima e hiki ai ke hana i nā block density, e hana pololei ana a me ka ikaika o nā'ōiwi a me ka ikaika o nā wai. Hiki i ka mīkini ke hana i nā poloka haʻahaʻa haʻahaʻa me ka maikaʻi maikaʻi. Hiki iā ia ke hana i ka nui kiʻekiʻe ma ka 40g / l a me ka haʻahaʻa haʻahaʻa ma 4g / l.

Hoʻopiliʻo Polystyrene i nā mīkini Willing Wireing me ka hakahaka o ke kino me ka mana o ka mīkini, ka pahu mālama,'ōnaehana, hoʻololi i ka'ōnaehana

Hoʻopiliʻo Polystyrene i nā mīkini Willing Widing me nā mea ponoʻole:

Ua hanaʻiaʻo 1.Machine i kahi kiʻekiʻe loa o nā hōʻailona kiʻekiʻe.

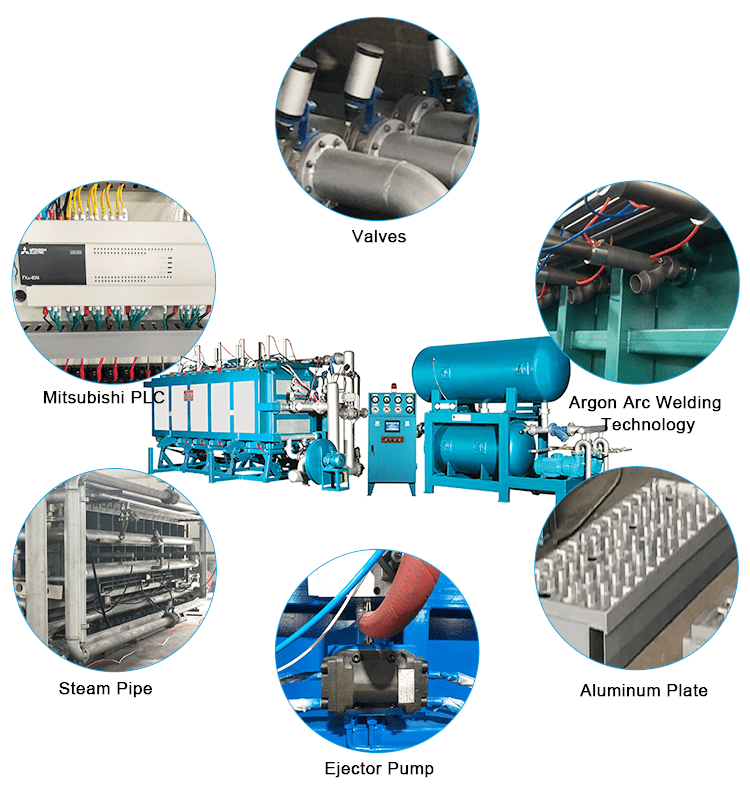

2. Ua hoʻohanaʻo 2.Machine i nā papa inoaʻo 5mm alumini a me nā papa inoaʻo Aluminim A ma lalo o ka papaʻaina alumini, ua kākoʻo nuiʻia nā kākoʻo nui ma ka nui o ka nui o ka nui o ka nui o ka nui o ka hoʻonuiʻana i ka nui o keʻano kiʻekiʻe. ʻO nā papa Aluminum't hoʻololi i ka palapala ma hope o nā makahiki heʻumi;

3.Mai Kakaki's all a pau nā paneʻeono ma o ka mālama wela e hoʻokuʻu i ke kaumaha,ʻaʻole hiki i kēlā mau pākeke ke nānā i lalo o ka mahana kiʻekiʻe;

4.Maicine me nā laina Steam e hōʻoia ai i kaʻaihueʻana ma nā poloka, no laila ua maikaʻi ka wikiwiki;

5. Ua maikaʻi nā papa hana me ka hoʻolālāʻana i nā brainage no nā blog a hiki ke maloʻo a hiki keʻoki i ka manawa pōkole;

6. Ma nā papa mīkini e lele ai i ka leleʻana, e pīhoihoi ana, a laila hanaʻo Anti -ʻAʻole maʻalahi ke kaomiʻana i ka mīkini

7.Machine E hoʻohana i ka'ōnaehana pīpī akamai a me ka hoʻopauʻana i ke kaʻina hana, e hōʻoia ana i ka wikiwiki o nā poloka a me nā haʻahaʻa kiʻekiʻe;

8.Cast hoʻopiha piha a me ka maikaʻi o ka'ōnaehana e hōʻoia i ka mīkini e hana wikiwiki ana, ma kēlā me kēia poloka 4 ~ 8 mau minuke;

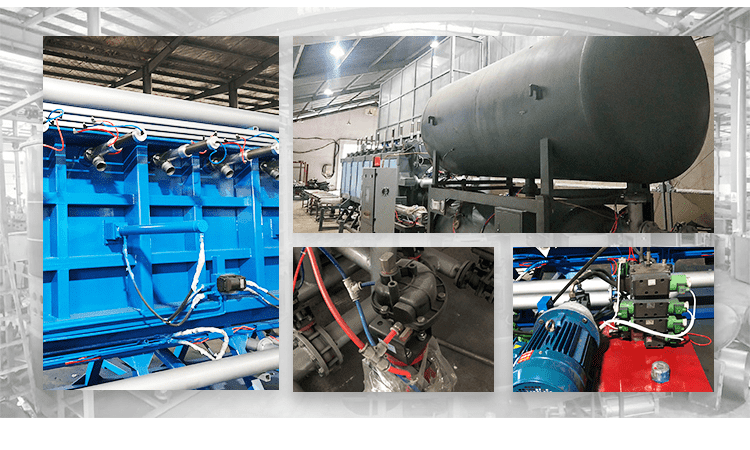

9.EJibection e mālamaʻia e ka pā hydraulic

10.ʻO nā'āpana waiwai i hoʻohanaʻia i loko o ka mīkini i laweʻia a iʻole nā huahana kaulana kaulana kaulana.

ʻO nā hiʻohiʻona koʻikoʻi

Mea | Kōho | Pb2000v | Pb3000v | Pb4000v | Pb6000v | |

ʻO ka nui mold cavity | mm | 2040 * 1240 * 1030 | 3060 * 1240 * 1030 | 4080 * 1240 * 1030 | 6100 * 1240 * 1030 | |

Poloka | mm | 2000 * 1200 * 1000 | 3000 * 1200 * 1000 | 4000 * 1200 * 1000 | 6000 * 1200 * 1000 | |

Māhu | Ke komo | Loko | 2 '(DN50) | 2 '(DN50) | 6 '(DN150) | 6 '(DN150) |

Kālā | Kg / cycle | 25 ~ 45 | 45 ~ 65 | 60 ~ 85 | 95 ~ 120 | |

Ka paipai | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Ka hau | Ke komo | Loko | 1.5 '' (dn40) | 1.5 '' (dn40) | 2 '(DN50) | 2 '(DN50) |

Kālā | M³ / keke | 1.5 ~ 2 | 1.5 ~ 2.5 | 1.8 ~ 2.5 | 2 ~ 3 | |

Ka paipai | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

ʻO ka wai hoʻomaha hoʻomaha | Ke komo | Loko | 1.5 '' (dn40) | 1.5 '' (dn40) | 1.5 '' (dn40) | 1.5 '' (dn40) |

Kālā | M³ / keke | 0.4 | 0.6 | 0.8 | 1 | |

Ka paipai | Mpa | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | |

Drainage | Drain brain | Loko | 4 '' (DN100) | 5 '' (dn125) | 5 '' (dn125) | 6 '(DN150) |

Iho i lalo | Loko | 4 '' (DN100) | 5 '' (dn125) | 6 '(DN150) | 6 '(DN150) | |

Ean motary vent | Loko | 4 '' (DN100) | 4 '' (DN100) | 6 '(DN150) | 6 '(DN150) | |

Kepani 15Kg / M³ | Min / cycle | 4 | 5 | 7 | 8 | |

Hoʻopili i ka ukana / mana | Kw | 19.75 | 23.75 | 24.5 | 32.25 | |

ʻO ka dimension holoʻokoʻa (L * h * w) | mm | 5700 * 4000 * 2800 | 7200 * 4500 * 3000 | 11000 * 4500 * 3000 | 12600 * 4500 * 3100 | |

Ke kaumaha | Kg | 5000 | 6500 | 10000 | 14000 | |

Laina

Nā wikiō pili maikaʻi

As an Eps Ejector Manufacturer, our machine's design incorporates a vacuum system, ensuring precise moulding of EPS blocks. This feature provides remarkable savings in terms of time and energy, contributing to an eco-friendly manufacturing process. Our product is not just about making EPS blocks; it's about delivering quality, efficiency, and sustainability in every block produced. At DongShen, we understand the needs of the industry. Our commitment as an Eps Ejector Manufacturer goes beyond just delivering machines; we provide full-fledged solutions to assist our clients in enhancing their manufacturing capabilities. By choosing our Polystyrene block moulding machine with vacuum, you choose superior performance, quality, and sustainability. Explore our innovative product range and make a smart choice for your business. Partner with DongShen, your trusted Eps Ejector Manufacturer, to leverage the power of advanced block moulding solutions.