ʻO kaʻokiʻoki'ē aʻe

Nā 'Detailslelo kiko'ī

Hoʻohanaʻia ka mīkini uila eps styrofoam e hana i nā poloka eps e hana ai, a laila eʻoki i nā pale no ka hoʻopaʻaʻana i ka hale Nā huahana kaulana i hanaʻia mai nā'āpana eps eps ipswelich, 3d palt, inner

ʻO nā mea eps styrofoam block molding i kūpono no ka noi liʻiliʻi liʻiliʻi a me nā haʻahaʻa haʻahaʻa haʻahaʻa a me nā mīkini waiwai e pili ana i ka mīkini. Me kaʻenehana kūikawā

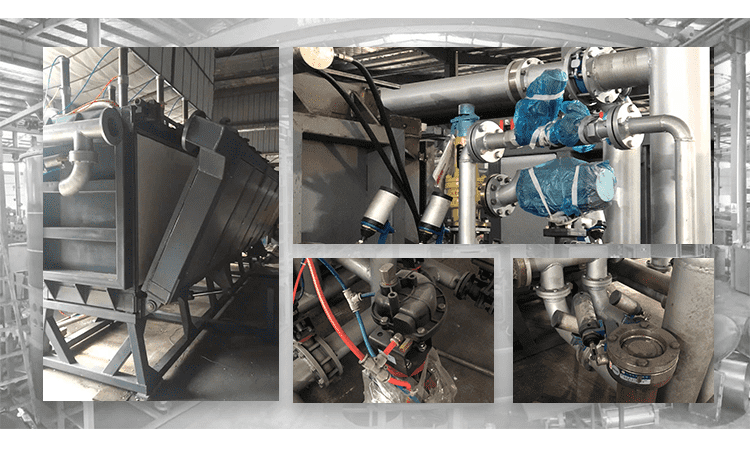

Hoʻopili ka mīkini me ke kino nui, ka pahu hoʻokele, ka mea puhi, ka mea kaupaona etc.

Nā hiʻohiʻona nui

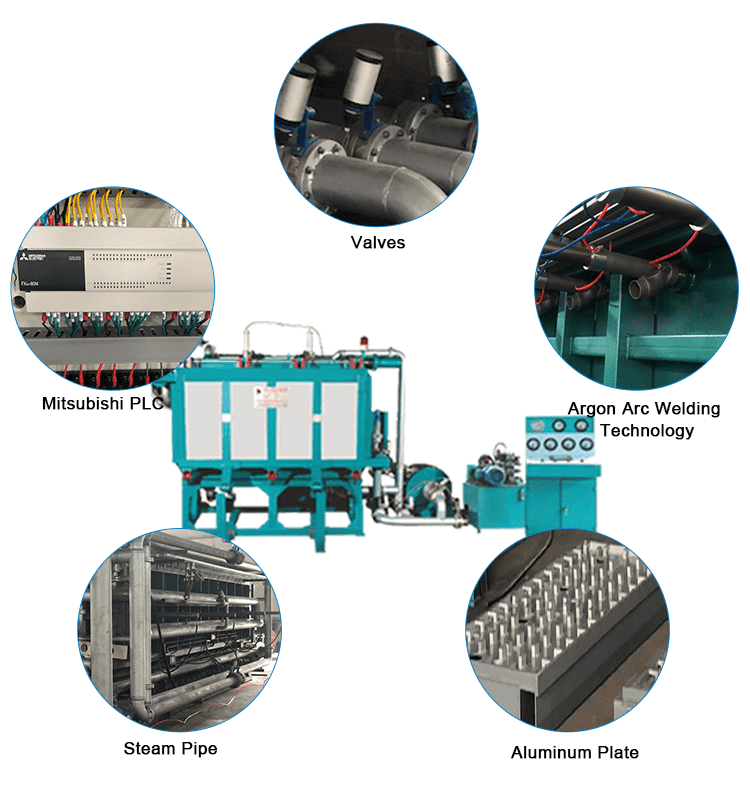

1.ʻO nā mīkini editts Mitsubishi plc a me Wintern patch i ka weheʻana i ka weheʻana, ka hoʻopihaʻana, a me ka hoʻoluʻuʻana, ka hoʻoluʻuʻana, ka leʻaleʻa

2.ʻO nā papa hana o nā mīkiniʻeonoʻeono ma waena o ka mālama wela e hoʻokuʻu i ke kaumaha, no lailaʻaʻole hiki i nā panils ke hōʻemi ma lalo o ka mahana kiʻekiʻe;

3.ʻO ka melold cavity i hanaʻia i ka papaʻalu piha piha loa me ka papaʻaina - Pono e kaohi i ka helu 5mm

4. Ua hoʻonohonohoʻia ka mīkini i kiʻekiʻe loa -ʻO ka pohō ikaika no nā mea waiwai. Hanaʻiaʻo Cooking e ka hau e pili ana i ka pā.

5. Mai kiʻekiʻe nā papa mīkini mai ke kiʻekiʻe o ka CIVIL FILL. Ma ka mālama wela, ikaika aʻaʻohe ikaika.

6. Ua mālamaʻiaʻo Ejection e Hydraulic Bump

ʻO nā hiʻohiʻona koʻikoʻi

Mea | Kōho | PB2000A | PB3000A | Pb4000a | PB6000A | |

ʻO ka nui mold cavity | mm | 2040 * 1240 * 630 | 3060 * 1240 * 630 | 4080 * 1240 * 630 | 6100 * 1240 * 630 | |

Poloka | mm | 2000 * 1200 * 600 | 3000 * 1200 * 600 | 4000 * 1200 * 600 | 6000 * 1200 * 600 | |

Māhu | Ke komo | Loko | Dn80 | Dn80 | Dn100 | Dn150 |

Kālā | Kg / cycle | 18 ~ 25 | 25 ~ | 40 ~ 50 | 55 ~ 65 | |

Ka paipai | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Ka hau | Ke komo | Loko | Dn40 | Dn40 | Dn50 | Dn50 |

Kālā | M³ / keke | 1 ~ 1.2 | 1.2 ~ 1.6 | 16 ~ 2 | 2 ~ 2.2 | |

Ka paipai | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Drainage | Steam vent | Loko | Dn100 | Dn150 | Dn150 | Dn150 |

Kepani 15Kg / M³ | Min / cycle | 4 | 5 | 7 | 8 | |

Hoʻopili i ka ukana / mana | Kw | 6 | 8 | 9.5 | 9.5 | |

ʻO ka dimension holoʻokoʻa (L * h * w) | mm | 3800 * 2000 * 2100 | 5100 * 2300 * 2100 | 6100 * 2300 * 2200 | 8200 * 2500 * 3100 | |

Ke kaumaha | Kg | 3500 | 5000 | 6500 | 9000 | |

Laina

Nā wikiō pili maikaʻi

From the first use, the EPS Cutter demonstrates how effortlessly it takes an EPS block and transforms it into a molded masterpiece. The results are uniformly shaped styrofoam sheets that exceed expectations and truly sets it apart from the competition. Whatever your EPS block molding needs are, our EPS Cutter is here to deliver. It is not just a machine; it is your partner in ensuring that every EPS block is molded to perfection. Try our EPS Cutter today and experience a new standard in EPS block molding efficiency.