Eʻike i ka Revolutionary Dongshen Styrofoam Styrofotor no ka EPS Foam Block

Nā 'Detailslelo kiko'ī

Ua hoʻonuiʻiaʻo Polystyrene Foam Boot Blolat block e hana i ka mīkini hana e hana i nā poloka eps, a laila eʻoki i nā pale no ka hoʻopaʻaʻana i ka hale kūʻai hale a iʻole ka paleʻana. Nā huahana kaulana i hanaʻia mai nā'āpana eps eps ipswelich, 3d palt, inner

Hoʻonuiʻiaʻo Polystyrene Foam Foum Blolat block e hana i ka mīkini i kūpono no ka noiʻana o ka mīkini liʻiliʻi. Me kaʻenehana kūikawā

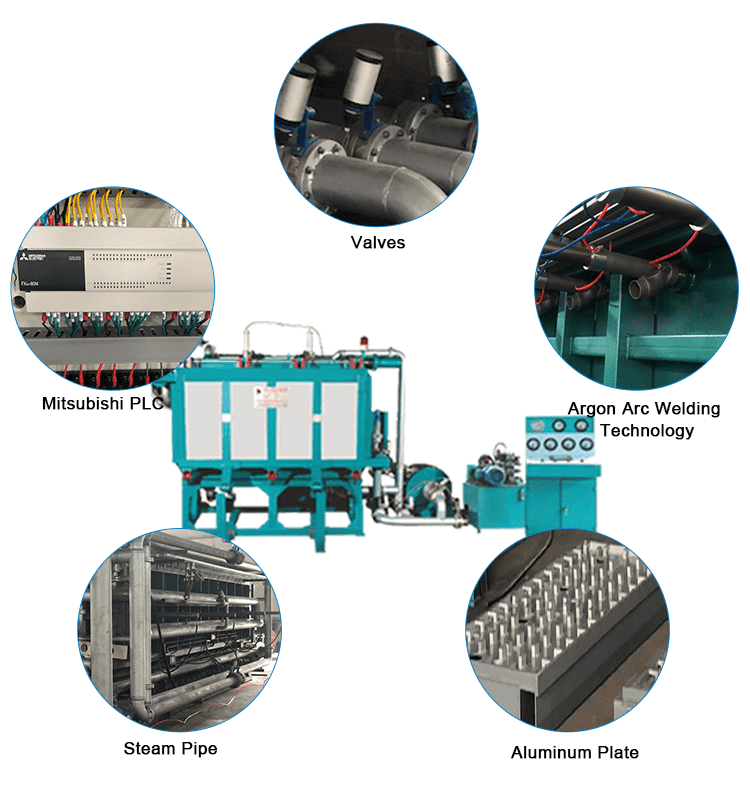

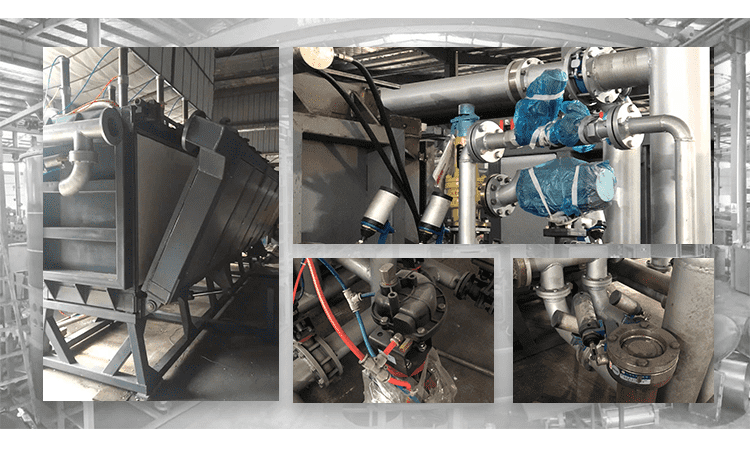

Hoʻopili ka mīkini me ke kino nui, ka pahu hoʻokele, ka mea puhi, ka mea kaupaona etc.

Nā hiʻohiʻona nui

1.ʻO nā mīkini editts Mitsubishi plc a me Wintern patch i ka weheʻana i ka weheʻana, ka hoʻopihaʻana, a me ka hoʻoluʻuʻana, ka hoʻoluʻuʻana, ka leʻaleʻa

2.ʻO nā papa hana o nā mīkiniʻeonoʻeono ma waena o ka mālama wela e hoʻokuʻu i ke kaumaha, no lailaʻaʻole hiki i nā panils ke hōʻemi ma lalo o ka mahana kiʻekiʻe;

3.ʻO ka melold cavity i hanaʻia i ka papaʻalu piha piha loa me ka papaʻaina - Pono e kaohi i ka helu 5mm

4. Ua hoʻonohonohoʻia ka mīkini i kiʻekiʻe loa -ʻO ka pohō ikaika no nā mea waiwai. Hanaʻiaʻo Cooking e ka hau e pili ana i ka pā.

5. Mai kiʻekiʻe nā papa mīkini mai ke kiʻekiʻe o ka CIVIL FILL. Ma ka mālama wela, ikaika aʻaʻohe ikaika.

6. Ua mālamaʻiaʻo Ejection e Hydraulic Bump

ʻO nā hiʻohiʻona koʻikoʻi

Mea | Kōho | PB2000A | PB3000A | Pb4000a | PB6000A | |

ʻO ka nui mold cavity | mm | 2040 * 1240 * 630 | 3060 * 1240 * 630 | 4080 * 1240 * 630 | 6100 * 1240 * 630 | |

Poloka | mm | 2000 * 1200 * 600 | 3000 * 1200 * 600 | 4000 * 1200 * 600 | 6000 * 1200 * 600 | |

Māhu | Ke komo | Loko | Dn80 | Dn80 | Dn100 | Dn150 |

| Kālā | Kg / cycle | 18 ~ 25 | 25 ~ | 40 ~ 50 | 55 ~ 65 |

| Ka paipai | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 |

Ka hau | Ke komo | Loko | Dn40 | Dn40 | Dn50 | Dn50 |

| Kālā | M³ / keke | 1 ~ 1.2 | 1.2 ~ 1.6 | 16 ~ 2 | 2 ~ 2.2 |

| Ka paipai | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 |

Drainage | Steam vent | Loko | Dn100 | Dn150 | Dn150 | Dn150 |

Kepani 15Kg / M³ | Min / cycle | 4 | 5 | 7 | 8 | |

Hoʻopili i ka ukana / mana | Kw | 6 | 8 | 9.5 | 9.5 | |

ʻO ka dimension holoʻokoʻa (L * h * w) | mm | 3800 * 2000 * 2100 | 5100 * 2300 * 2100 | 6100 * 2300 * 2200 | 8200 * 2500 * 3100 | |

Ke kaumaha | Kg | 3500 | 5000 | 6500 | 9000 | |

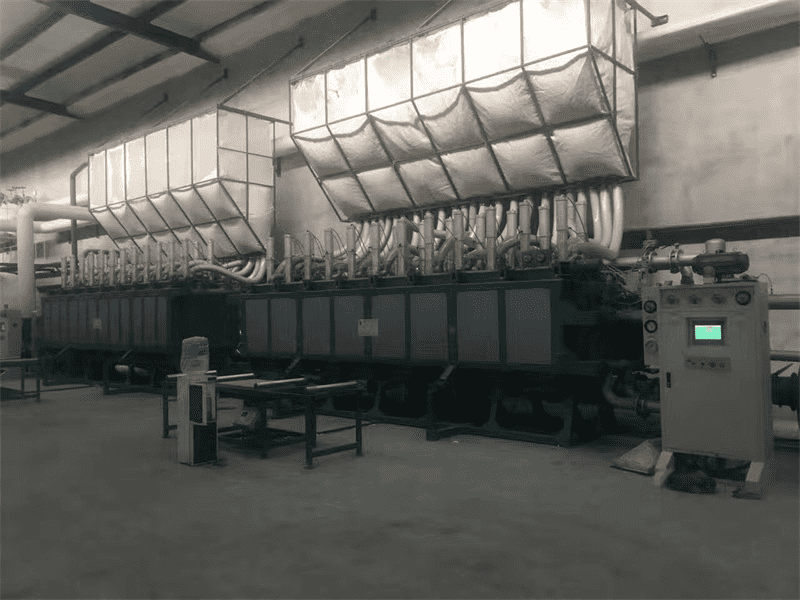

Laina

Nā wikiō pili maikaʻi

Using the Styrofoam Granulator is an incredible way to keep production costs down while enhancing output quality. Its ease of operation and maintenance further adds to the productivity of the process, making it an indispensable tool for any industry relying on EPS foam blocks. In conclusion, Dongshen's Styrofoam Granulator is not only a game-changer in the production of EPS foam blocks, but it is also a significant step towards developing more sustainable and efficient industrial processes. Relying on this machine means entrusting the production of your EPS foam blocks to a fast, reliable, and cost-effective solution, which ultimately leads to maximized productivity and profitability in your operations. Trust in Dongshen’s innovation to meet and exceed your industry's requirements.