Ba tare da unparalle eps forming na'urar - Donghen EPS

Bayanan samfurin

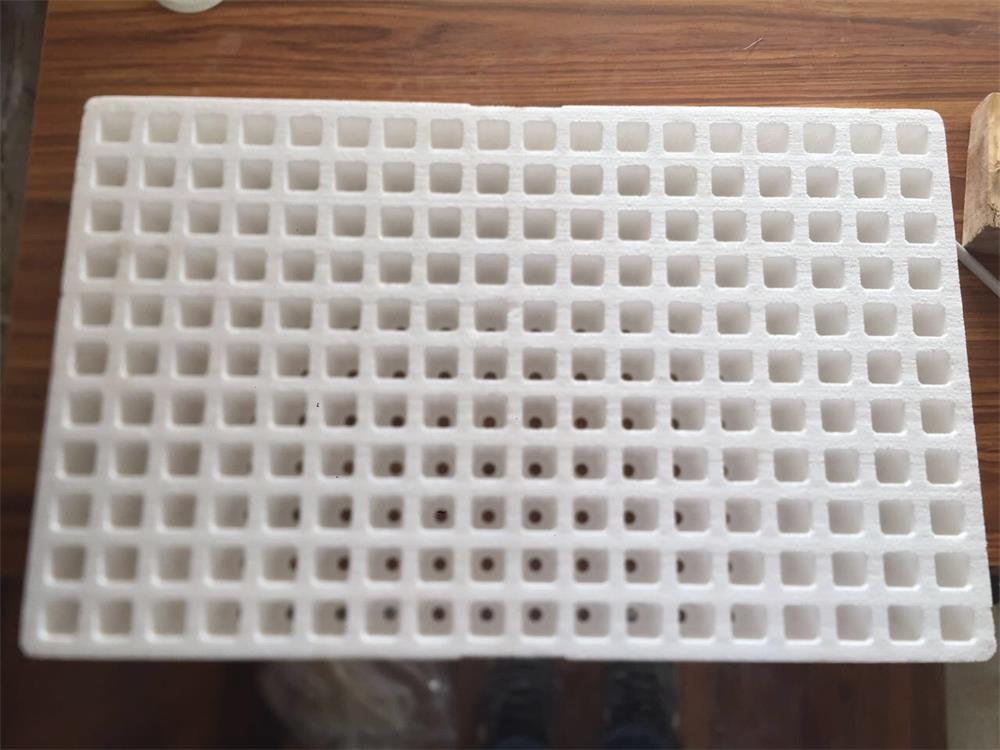

Ana amfani da injin polystyrene tare da mold don samar da samfuran marufi kamar kayan aikin da ICF ɗin, injiniyoyi na iya samar da sifa daban-daban.

Tsarin mai ceton kuɗaɗen ƙirar mold, tsarin hydraulic, da tsarin magudanar sauri. Don samfurin iri ɗaya, lokacin sake zagayowar cikin injin shine 25% ya fi guntu da injin al'ada, da kuma yawan kuzari shine 25% ƙasa.

Injin ya kammala tare da PLC, taɓawa allon, cika tsarin, tsarin iska, tsarin hydraulic, akwatin lantarki, akwatin lantarki, akwatin lantarki, akwatin lantarki, akwatin lantarki, akwatin lantarki, akwatin lantarki, akwatin lantarki, akwatin lantarki, akwatin lantarki, akwatin lantarki, akwatin lantarki, akwatin lantarki

FAV1200E - 1750e fadada injin polystyrene injin (ingantaccen aiki)

Babban fasali

1.Machine faranti an yi shi da fararen karfe don haka yana da dadewa;

2.Machine yana da ingantaccen tsarin voirpe, injin gida da tanki na baya;

3.Machine amfani da tsarin hydraulic mai sauri, adana maɓallin rufewa da lokacin budewa;

4.Da hanyoyin cika hanyoyin da ake cike da su don guje wa cika matsala a samfurori na musamman;

5.Machine yana amfani da babban tsarin bututu mai girma, yana ba da izinin ƙarancin matsin lamba. 3 ~ 4 Surge Steam na iya aiki da injin;

6.Kachine tururi Steam da shigar da shigar ciki yana sarrafawa ta hanyar matsin lamba ta Jamusanci da kuma matsakaiciyar ayyukan da ke sarrafawa;

7.com An shigo da abubuwan da ake amfani da su a cikin injin galibi ana shigo da su kuma sanannun samfuran da aka san su, ƙananan ɓarna;

8.Machine tare da dagawa kafafu, don haka abokin ciniki ne kawai ke buƙatar yin dandamali mai aiki don ma'aikata.

Babban sigogi na fasaha

| Kowa | Guda ɗaya | Fav1200e | FAV1400E | Fav1600e | FAV1750e | |

| M girma | mm | 1200 * 1000 | 1400 * 1200 | 1600 * 1350 | 1750 * 1450 | |

| Matsakaicin samfurin Max | mm | 1000 * 800 * 400 | 1200 * 1000 * 400 | 1400 * 1150 * 400 | 1550 * 1250 * 400 | |

| Bugun jini | mm | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | |

| Tururi | Shigowa | Inke | 3 '' (DN80) | 4 '' (DN100) | 4 '' (DN100) | 4 '' (DN100) |

| Amfani | KG / sake zagayowar kilogram | 4 ~ 7 | 5 ~ 9 | 6 ~ 10 | 6 ~ 11 | |

| Matsa lambu | MPA | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | |

| Ruwa mai sanyaya ruwa | Shigowa | Inke | 2.5 '' (DN65) | 3 '' (DN80) | 3 '' (DN80) | 3 '' (DN80) |

| Amfani | KG / sake zagayowar kilogram | 25 ~ 80 | 30 ~ 90 | 35 ~ 100 | 35 ~ 100 | |

| Matsa lambu | MPA | 0.3 ~ 0.5 | 0.3 ~ 0.5 | 0.3 ~ 0.5 | 0.3 ~ 0.5 | |

| A iska | Ingancin Ingantaccen Matsakaicin Matsayi | Inke | 2 '' (DN50) | 2.5 '' (DN65) | 2.5 '' (DN65) | 2.5 '' (DN65) |

| Low matsin lamba | MPA | 0.4 | 0.4 | 0.4 | 0.4 | |

| Take kai tsaye | Inke | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | |

| Babban matsin lamba | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

| Amfani | M³ / Catcle | 1.5 | 1.8 | 1.9 | 2 | |

| Magua | Inke | 5 '' DN125) | 6 '' (DN150) | 6 '' (DN150) | 6 '' (DN150) | |

| Capacit15kg / M³ | S | 60 ~ 110 | 60 ~ 120 | 60 ~ 120 | 60 ~ 120 | |

| Haɗa kaya / iko | Kw | 9 | 12.5 | 14.5 | 16.5 | |

| Gaba daya girma (l * w * h) | mm | 4700 * 2000 * 4660 | 4700 * 2250 * 4660 | 4800 * 2530 * 4690 | 5080 * 2880 * 4790 | |

| Nauyi | Kg | 5500 | 6000 | 6500 | 7000 | |

Harka

Mai dangantaka mai dangantaka

The core competencies of the Machine EPS lie within its design and functionality. The machine has been engineered with a focus on the user interface, ensuring a smooth and straightforward operation. Moreover, it boasts an exceptional operational efficiency, drastically reducing production time without compromising on the quality of the final packaging product. It has been tailored specifically to meet your production demands, providing you with the capability to create diverse packaging products while adhering to the highest quality and safety standards. In conclusion, DongShen's Machine EPS is the optimal choice for manufacturers seeking to revolutionize their EPS packaging process. This machine brings unprecedented precision, reliability, and efficiency to your production line, solidifying your place in the competitive packaging industry. Put your trust in DongShen's Machine EPS, and experience the revolution in EPS packaging production.