Babban EPs ya toshe hanyoyin magance mafita daga jagorancin EPS ES Ejects Man masana'antu, Dongshen

Bayanan samfurin

Polystyrene tuya injin molmin mashin tare da vacuum inji inji na EPS don yin tubalan EPS. Ana iya yanke tubalan EPS zuwa zanen gado don rufin gida ko shirya. Shahararrun kayayyakin da aka yi ne daga zanen EPS sune bangarorin sandwi, bangels na 3D, ciki da waje bango bangs, shirya fakitin da sauransu.

Polystyrene tuya na'ura mold mashin da wuri na iya samar da babban yawa eps, aiki a cikin sake zagayowar sauri, kuma duk shinge suna madaidaiciya kuma suna da ƙarancin danshi. Hakanan injin din na iya yin ƙananan tubalan tare da inganci mai kyau. Zai iya yin babban rauni a 40G / l da ƙananan yawa a 4g / l.

Polystyrene tuki mai launin mold m inji tare da injin cikakke tare da babban injin, akwatin sarrafawa, tsarin computeum, tsarin yin nauyi da sauransu.

Polystyrene tuya injin mold inji tare da m fa'idodi:

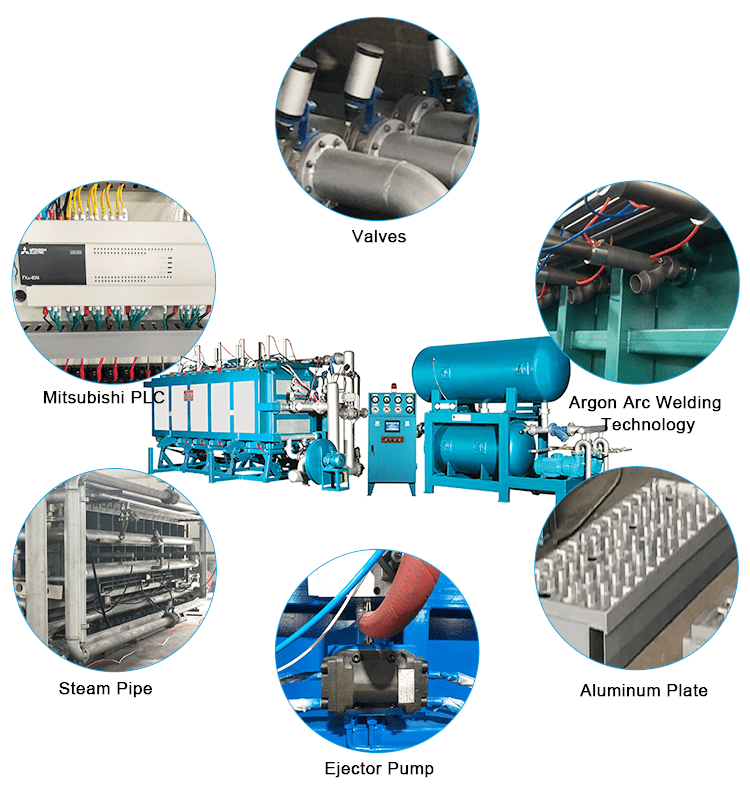

1.Machine an yi shi da sittin - tsayin murabba'in murabba'in karfe da kuma murfin karfe;

2.machine yana amfani da 5mm mai kauri mai kauri tare da kayan teflon. Kuma a karkashin farantin aluminium, manyan abubuwan tallafawa ana sanya su don magance farantin aluminium a ƙarƙashin matsanancin matsin lamba. Farayen Aluminum yayi't canza canji bayan shekaru goma suna aiki;

3.Machine'S Dukkan bangarori shida suna ta hanyar magani mai zafi don saki walwalwar damuwa, saboda haka bangarorin ba zasu iya lalata ba a ƙarƙashin babban zazzabi;

4.Machine tare da ƙarin layin tururi don tabbatar da tururi har ma a cikin katanga, don haka toshe fuska mai kyau;

5.Machine farantin suna tare da mafi kyawun tsarin magudanar don haka tubalan sun fi bushe kuma ana iya yanke su cikin ɗan gajeren lokaci;

6. Wallt faranti ta hanyar cire tsatsa.

7.Machine amfani da tsarin pipping da tsarin tururi, tabbatar da kyakkyawan haɓakar ƙwayoyin cuta da ƙarancin yawa;

8. Cika tsarin cikar da ingantaccen tsarin yana yin aiki mai sauri, kowane toshe 4 ~ 8 minti;

9.Etega da ke sarrafawa ta hanyar m slumpusa, don haka duk masu fitar da kai suka koma daidai da;

10. An shigo da kayan haɗin 10. Ana amfani dasu a cikin injin din ko shahararrun samfurori.

Babban sigogi na fasaha

Kowa | Guda ɗaya | Pb2000v | Pb3000v | Pb4000v | Pb6000v | |

Girman hankali | mm | 2040 * 1240 * 1030 | 3060 * 1240 * 1030 | 4080 * 1240 * 1030 | 6100 * 1240 * 1030 | |

Girman toshe | mm | 2000 * 1200 * 1000 | 3000 * 1200 * 1000 | 4000 * 1200 * 1000 | 6000 * 1200 * 1000 | |

Tururi | Shigowa | Inke | 2 '' (DN50) | 2 '' (DN50) | 6 '' (DN150) | 6 '' (DN150) |

Amfani | KG / sake zagayowar kilogram | 25 ~ 45 | 45 ~ 65 | 60 ~ 85 | 95 ~ 120 | |

Matsa lambu | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

A iska | Shigowa | Inke | 1.5 '' (DN40) | 1.5 '' (DN40) | 2 '' (DN50) | 2 '' (DN50) |

Amfani | M³ / Catcle | 1.5 ~ 2 | 1.5 ~ 2.5 | 1.8 ~ 2.5 | 2 ~ 3 | |

Matsa lambu | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Ruwa mai sanyaya ruwa | Shigowa | Inke | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) |

Amfani | M³ / Catcle | 0.4 | 0.6 | 0.8 | 1 | |

Matsa lambu | MPA | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | |

Magua | Madaidai | Inke | 4 '' (DN100) | 5 '' DN125) | 5 '' DN125) | 6 '' (DN150) |

Saukar da tururi iska | Inke | 4 '' (DN100) | 5 '' DN125) | 6 '' (DN150) | 6 '' (DN150) | |

Air sanyaya iska | Inke | 4 '' (DN100) | 4 '' (DN100) | 6 '' (DN150) | 6 '' (DN150) | |

Mai karfin 15kg / M³ | Min / sake zagayowar min / zagayawa | 4 | 5 | 7 | 8 | |

Haɗa kaya / iko | Kw | 19.75 | 23.75 | 24.5 | 32.25 | |

Gaba daya girma (L * h * w) | mm | 5700 * 4000 * 2800 | 7200 * 4500 * 3000 | 11000 * 4500 * 3000 | 12600 * 4500 * 3100 | |

Nauyi | Kg | 5000 | 6500 | 10000 | 14000 | |

Harka

Mai dangantaka mai dangantaka

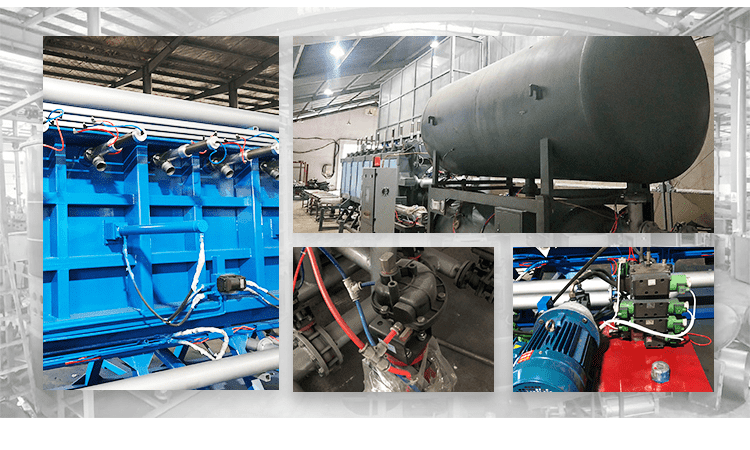

As an Eps Ejector Manufacturer, our machine's design incorporates a vacuum system, ensuring precise moulding of EPS blocks. This feature provides remarkable savings in terms of time and energy, contributing to an eco-friendly manufacturing process. Our product is not just about making EPS blocks; it's about delivering quality, efficiency, and sustainability in every block produced. At DongShen, we understand the needs of the industry. Our commitment as an Eps Ejector Manufacturer goes beyond just delivering machines; we provide full-fledged solutions to assist our clients in enhancing their manufacturing capabilities. By choosing our Polystyrene block moulding machine with vacuum, you choose superior performance, quality, and sustainability. Explore our innovative product range and make a smart choice for your business. Partner with DongShen, your trusted Eps Ejector Manufacturer, to leverage the power of advanced block moulding solutions.