Hoë - kwaliteit EPS -blokvormmasjien van Dongshen, die betroubare vervaardiger van die EPS -masjien

Produkbesonderhede

EPS -uitbreidbare polistireenmasjienvervaardiger het 'n doeltreffende vakuumstelsel, 'n vinnige hidrouliese stelsel en 'n vinnige dreineringstelsel. Vir dieselfde produk is die siklusstyd in die E -tipe masjien 25% korter as in die normale masjien, en energieverbruik is 25% minder.

EPS uitbreidbare polistireenmasjienvervaardiger voltooi met PLC, aanraakskerm, vulstelsel, doeltreffende vakuumstelsel, hidrouliese stelsel, elektriese vak

Belangrikste kenmerke

Masjienplate is van dikker staalplate gemaak, sodat dit lank bly;

Masjien het 'n doeltreffende vertikale vakuumstelsel, vakuumtenk en kondensortenk apart;

Masjiengebruik vinnige hidrouliese stelsel, bespaar die sluiting van die vorm en die openingstyd, met behulp van hoëdrukolie -silinder, hidrouliese druk 140 - 145balk, hidrouliese snelheid tot 250 mm/s.

Verskillende vulmetodes is beskikbaar om die probleem in spesiale produkte, rugdrukvulling, normale drukvulling, polsvulling, die keuse van onder druk, ens. Te voorkom.

Machine gebruik 'n groot pypstelsel, waardeur lae druk stoom kan wees. 3 ~ 4bar stoom kan die masjien werk;

Masjienverhittingstelsel gebruik Duitse druksensor om stoomdruk te beheer.

Komponente wat in die masjien gebruik word, word meestal ingevoer en beroemde handelsmerkprodukte, lae wanfunksionering;

Masjien met opheffing van bene, so kliënt hoef net 'n eenvoudige werkplatform vir werkers te maak.

Masjienstoomverbruik minder en werksdoeltreffendheid hoër.

Belangrikste tegniese parameters

| Item | Eenheid | Fav1200e | Fav1400e | Fav1600e | FAV1750E | |

| Vormafmeting | mm | 1200*1000 | 1400*1200 | 1600*1350 | 1750*1450 | |

| Maksimum produkafmeting | mm | 1000*800*400 | 1200*1000*400 | 1400*1150*400 | 1550*1250*400 | |

| Beroerte | mm | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | |

| Stoom | Binnekoms | Duim | 3 '' (DN80) | 4 '' (DN100) | 4 '' (DN100) | 4 '' (DN100) |

| Verbruik | Kg/siklus | 4 ~ 7 | 5 ~ 9 | 6 ~ 10 | 6 ~ 11 | |

| Druk | MPA | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | |

| Koelwater | Binnekoms | Duim | 2.5 '' (DN65) | 3 '' (DN80) | 3 '' (DN80) | 3 '' (DN80) |

| Verbruik | Kg/siklus | 25 ~ 80 | 30 ~ 90 | 35 ~ 100 | 35 ~ 100 | |

| Druk | MPA | 0.3 ~ 0.5 | 0.3 ~ 0.5 | 0.3 ~ 0.5 | 0.3 ~ 0.5 | |

| Saamgeperste lug | Lae druktoegang | Duim | 2 '' (DN50) | 2.5 '' (DN65) | 2.5 '' (DN65) | 2.5 '' (DN65) |

| Lae druk | MPA | 0.4 | 0.4 | 0.4 | 0.4 | |

| Hoë druktoegang | Duim | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | |

| Hoë druk | MPA | 0,6 ~ 0,8 | 0,6 ~ 0,8 | 0,6 ~ 0,8 | 0,6 ~ 0,8 | |

| Verbruik | m³/siklus | 1.5 | 1.8 | 1.9 | 2 | |

| Dreinering | Duim | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | 6 '' (DN150) | |

| Kapasiteit15 kg/m³ | S | 60 ~ 110 | 60 ~ 120 | 60 ~ 120 | 60 ~ 120 | |

| Verbind las/krag | Kw | 9 | 12.5 | 14.5 | 16.5 | |

| Algehele dimensie (l*w*h) | mm | 4700*2000*4660 | 4700*2250*4660 | 4800*2530*4690 | 5080*2880*4790 | |

| Gewig | Kg | 5500 | 6000 | 6500 | 7000 | |

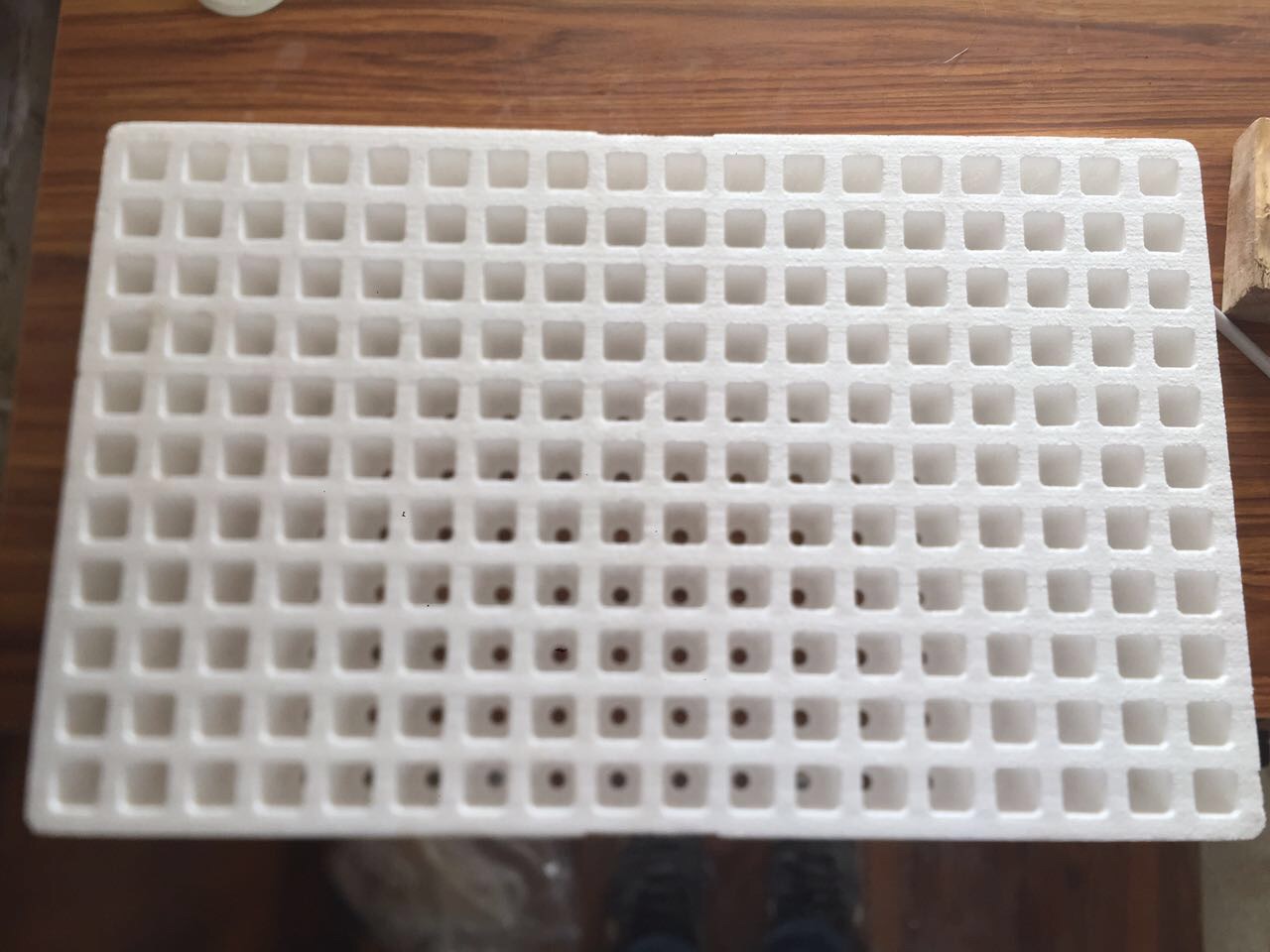

Saak

Verwante video

DongShen offers a wide range of machines to suit every EPS need. From EPS Injection Moulding Machine to EPS Sheet Making Machine, EPS Preforming Machine, EPS Panel Making Machine, EPS Block Cutting Machine, and more, we have you covered. Experience the power of efficient EPS production with DongShen, your reliable EPS Machine Manufacturer. Our commitment to quality and innovation is what keeps us at the top of the EPS machine manufacturing industry.